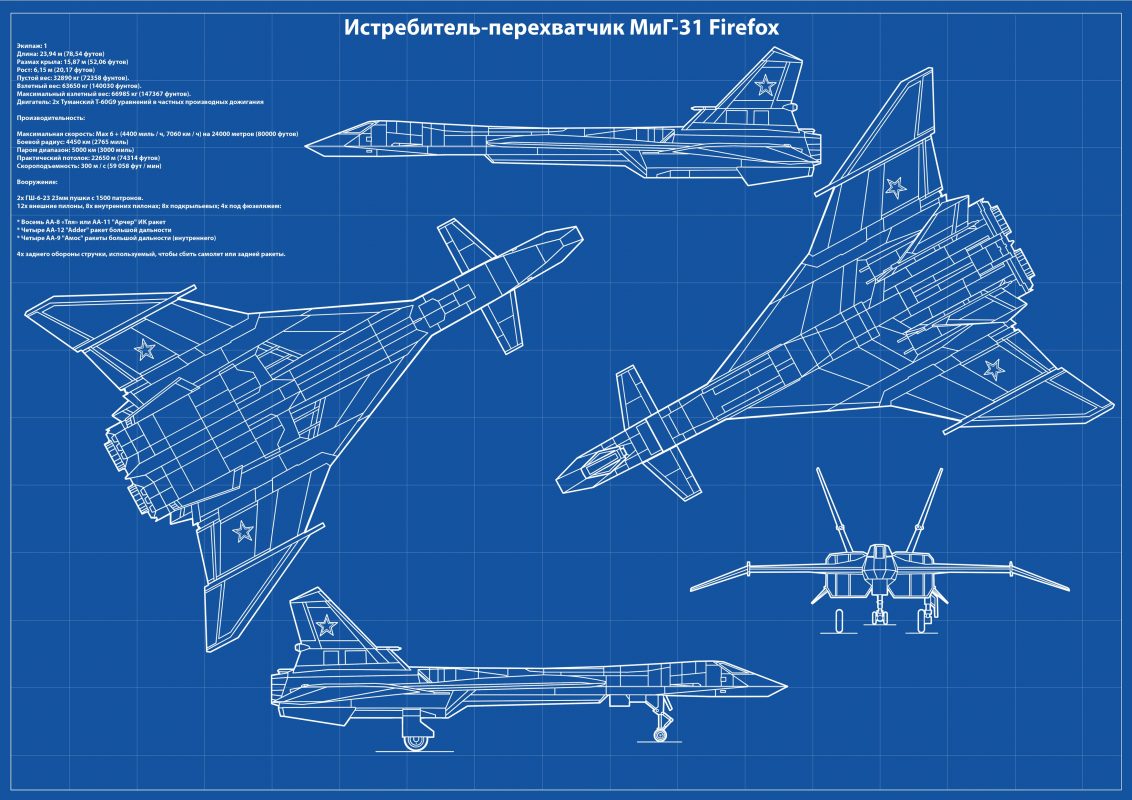

It goes MACH 6 and is ‘invisible’. This insane interceptor fighter is thought-guided and controlled. The Firefox MiG-31. You need to ‘think in Russian’ to get this jet to do it’s job.

In the past year and a half, I’ve invested a huge amount of time and resources developing an update to my state of the art all-road/hybrid platform. Before that, my focus was several rounds of development of the klunker platform. Those sagas tore me to bits. In the last three years, about 90% of my dirt rides have been fully rigid. The testing of these rigid bikes has hurt my wrists, and my arms are beat. I took a lot of risks in trying to find the limits of those bikes.

I learned about improved geometry and setup with those bikes, refining head angles and offsets in my designs, some front and rear center adjustments, and a lot more. What few understand is that rigid bikes are the best platform to study geometry as there is no hiding behind the range of rider error that suspension allows. If something isn’t working, you’ll find out right away on a rigid bike. You are forced to use perfect form or the bike slows to a crawl. As a few inches of suspension travel up front enters the picture, the struggle is to keep the improvements of these rigid bikes without introducing any negative features. We gain additional margins of error and an increase in amplitude with suspension. The cost can become parasitic if not done very well.

I want to boost trail with some front suspension again. I miss hucking deep into a rock garden in a way that only a bike with some degree of suspension allows. I do have a great bike for doing this, the 2018 Warbird, but it is a whole different bike than I want right now, for a few reasons. That bike is a very heavy hitter with the monster front end. I’m a bit older now and riding trail differently. The Warbird is also cast in a 4 year old development paradigm. So much has changed and I’ve learned a considerable amount developing the last few bikes. I want a highly efficient bike that rips up and down the hill. It should ‘feel’ great as well as slash trail. I want that speed! I want to smash without getting broken.

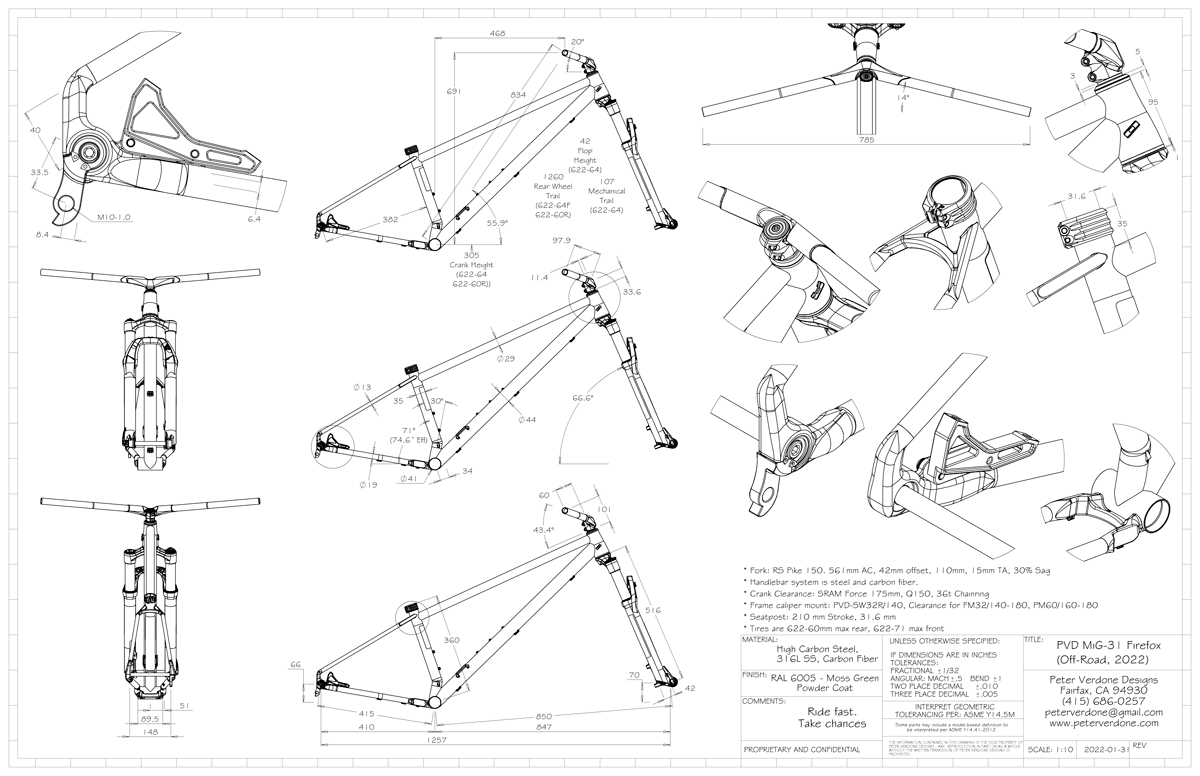

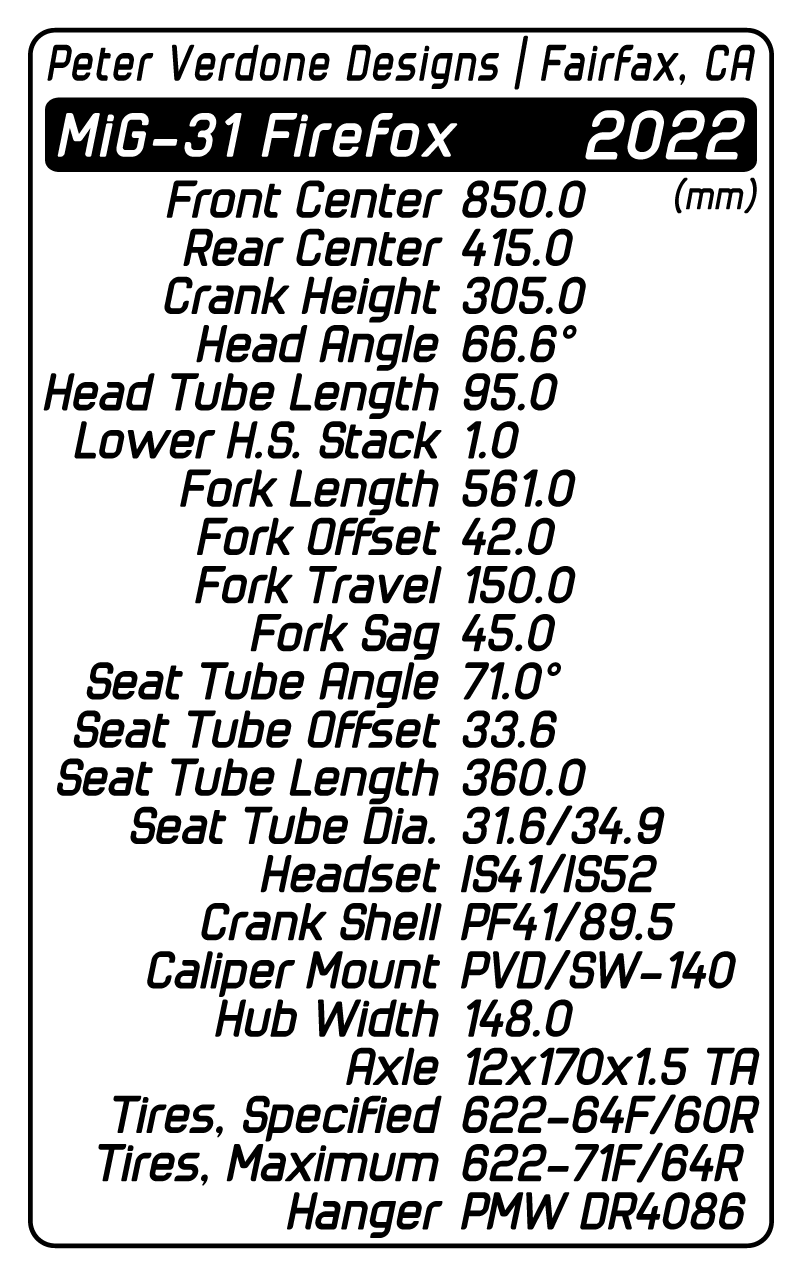

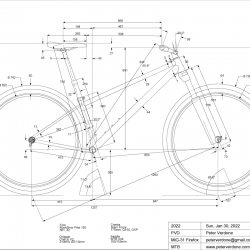

I’ve been using heavy forks on the front of my bikes since the 2016 Red Five (160mm, 170mm and 180mm Yari, Lyrik and ZEB). While these forks are awesome when pointed down the hill, they are very heavy and pull the front end of the bike down to the ground. I’m going to try using a new 150mm Pike fork (1844g). It’s 421g lighter than the ZEB 180 (2265g). I haven’t used a suspension fork this short since 2012. I’m expecting a pretty lively feel.

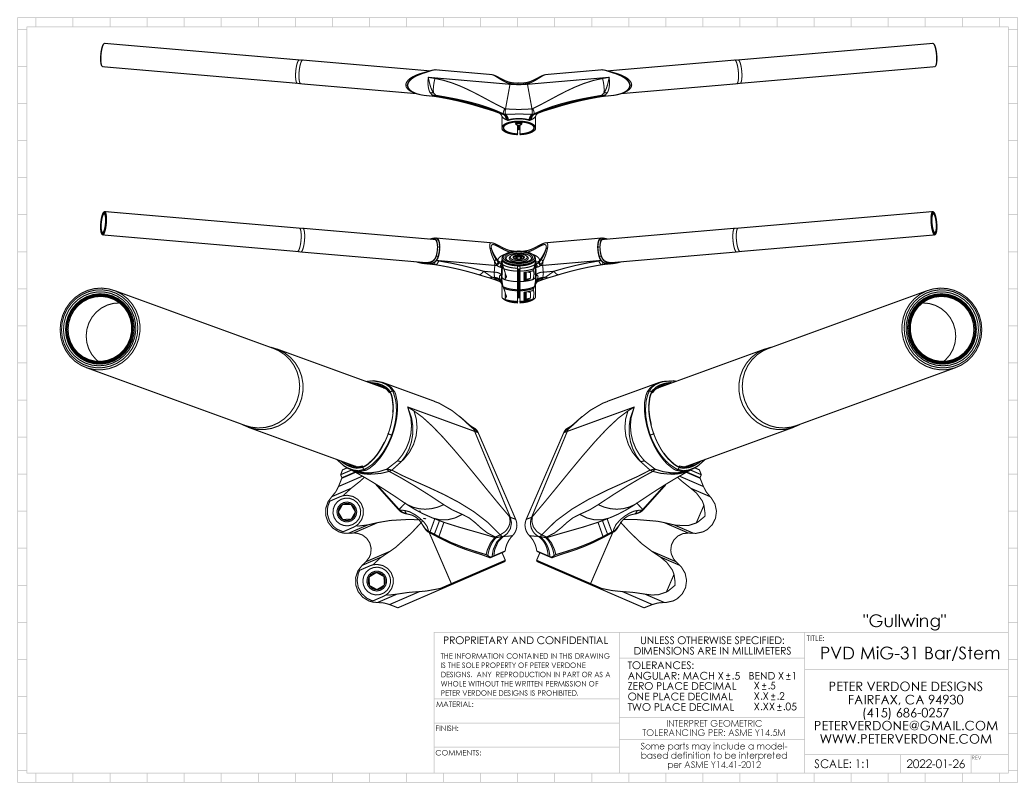

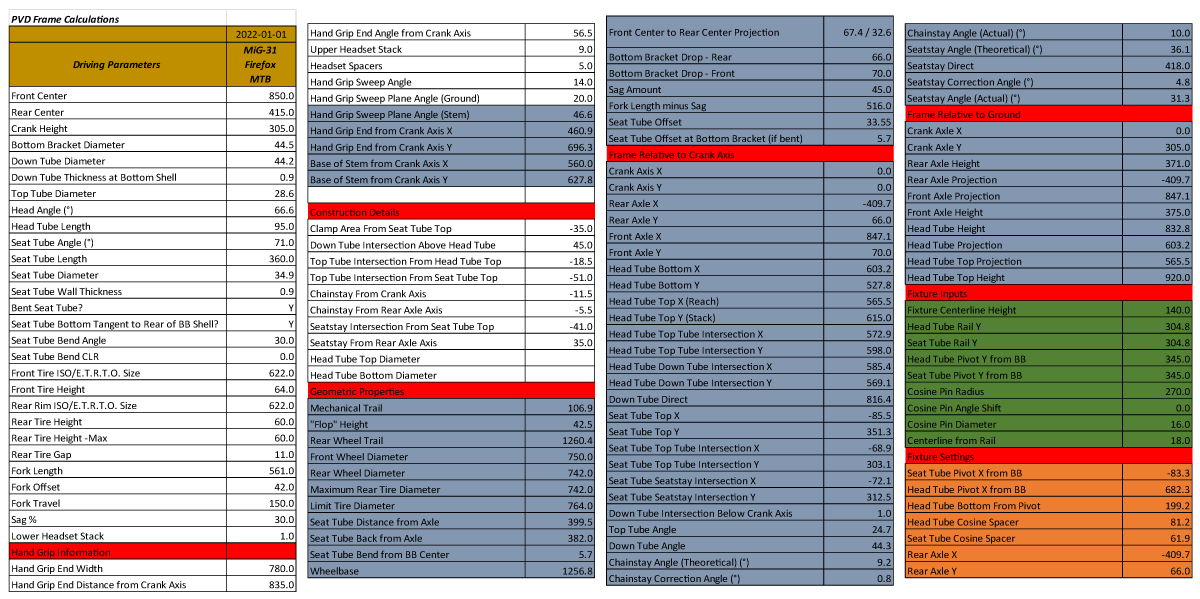

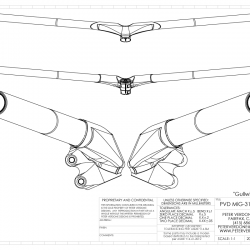

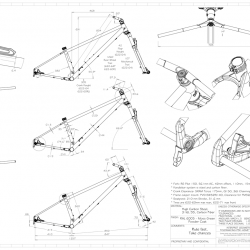

Geometry-wise, this bike marks a move to steeper head tube angles on my mountain bikes. I’ve established that 850mm of front center works pretty good for me on the local trails. Keeping that, I can look to other improvements, namely reducing front end flop. By pushing the stem/bar assembly to the design limit, I gained space that would allow the head to rock forward. The ‘gullwing’ bar/stem unit opens up the space that makes this the steeper head angle possible. This brings the flop height to 42mm which is pretty nice. 16% less than the 50mm of the Warbird with the ZEB 44mm offset fork.

I went through several iteration rounds on this design along with some plastic printing. I’m hoping that it’s strong and good looking. The wing feels very nice in the hand, a common hold point when off the bike. It’s a fabricated part for now. I may move to a fully printed version in the future.

These new gullwing bars solve the problem of an intersectional lug with some rise but not significant enough to be strutted. It was a tough code to crack. In that design is a 14 degree back sweep carried over from the TIE. I can understand the use of 9 degree in downhill or real heavy enduro racing but in general riding, the higher sweeps seem a lot nicer and open up the design. I may iterate on just what the right angle is but 14 is a lot closer than 9 and 16 is getting high, as used on the Klunkers.

Another major change on this bike are the Q150/52 cranks. It is common for mountain bikers to arbitrarily choose Q168 or Q177 cranks. The industry doesn’t want people educated on this as they have an easier time if they don’t. Also, nobody actually cares about fit. For the last decade or so, I’ve been using SRAM XX1 Q156 cranks on my mountain bikes. These are the narrowest production cranks that you could get for this application. The emphasis here is on ‘could’. They haven’t been available for many years and finding them on Ebay has gotten more and more difficult. I needed to make some moves on this front that would work into the future. This isn’t just a procurement problem. Going to a crank narrower than Q156 with the 52mm chainline is a design nightmare. How do you fit a 622-64 tire and a 36t chainring and have room for the crank arm ends and have heel clearance…all while having a structurally viable rear end? Ugh.

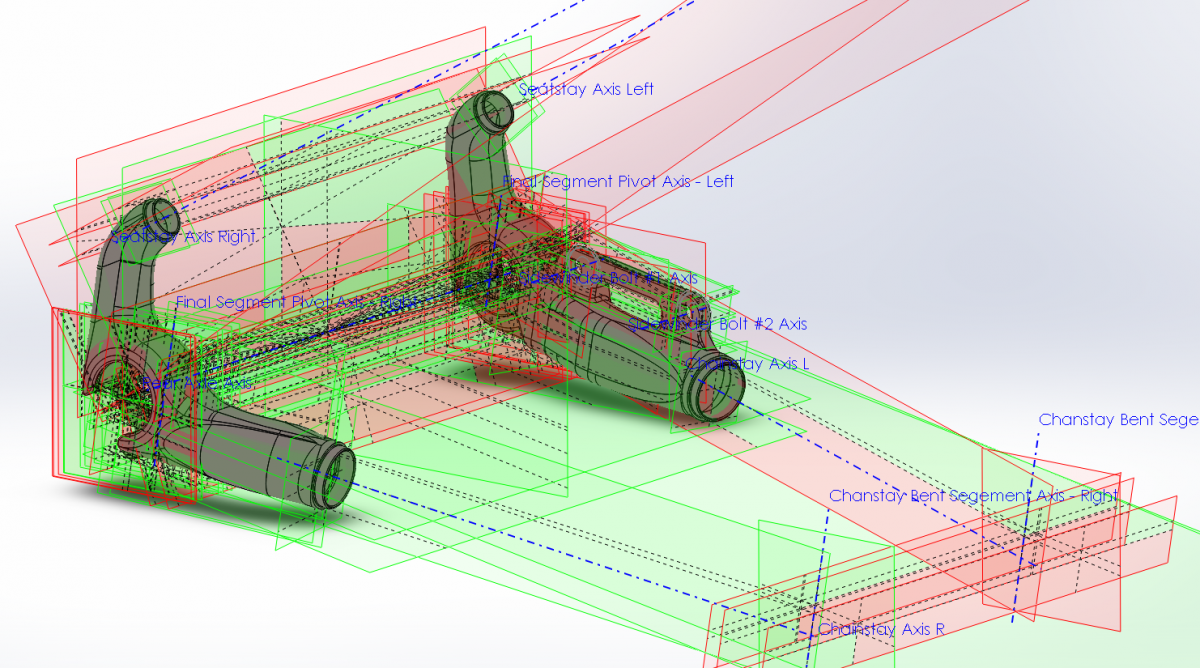

This is where 3D printing and a whole ton of design work come in. I played a lot of tricks in the design of the chainstay yoke and dropouts to have this come together. I checked and double checked…again and again.

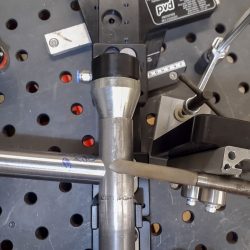

I had to produce a SRAM Force/S900 crankset with a ‘wide axle’ to go with a PF41/89.5 crank shell and some specially modified spacers. The PVD BoostR 1x Spider that I designed back in 2016 is key here. This means that the chainring has the most clearance possible. While test fitting parts before the frame went to paint, I modified a few old chainrings with counterbores.

I found a little space in the final assembly and was able to move the ring inward another 1mm to 51mm chainline for improved efficiency.

While I have a set of newer SRAM Force cranks that I would have liked to use on this bike, they use the newer 8-bolt spider pattern instead of the more established 3-bolt style. I’m going to get some new spiders done for these cranks but I didn’t have them on hand at the moment.

This may sound like a lot of effort but it’s obvious stuff for anyone that’s experienced assembling performance bikes. I’m exploiting each opportunity in the design.

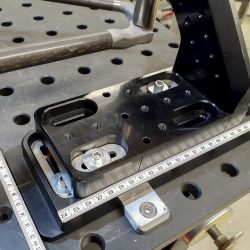

The dropout shape has changed a bit from the TIE. That frame used my first printed dropout design. It was pretty good but certainly not the end of the game. I rebuilt the design entirely for the Firefox. I’m looking to have something that is elegant, strong, light, and blends in with the rest of the drivetrain. I feel that this design does that better than the first. I’m hoping that the next is even better.

Significant effort in the dropout design was for pulling the stays toward the centerline of the bike. With the narrow crank and already having interaction issues with the chainstays, I wanted that minimized. I ride bikes regular footed and pulling in the drive side stay just a little more is good for me. With printing, we can do things like this without adding huge material and machining costs.

A set of braze-ons were designed to improve the cable routing for the new ‘underside’ routing that the industry is forcing on us. In this case, after some time, this has worked out well for my bikes. These new braze-on’s are the final piece to that puzzle. They bring the housing much closer to the frame and give more room for zip ties than commercially available items. Some side mounted housing mounts on the head tube improve the routing up front. This is wholly new for me and something never seen in metal bike frames…at least, for modern hose routing. Some builders had done this with STI adjustment stops on road bikes, but that was always terrible. Here it works. I was careful in laying out the routing to maximize fork crown clearance to the down tube which is more of an issue with the steeper head angle.

The new bag strap boss should make carrying cargo on the bike more stable. It’s light and strong and looks pretty cool. If nothing else, it will allow me to carry more on the bike. My wife is going to work on a PVD/WR bag soon as she is more the ‘bike packer’ type of the two of us.

The bike had been designed around a 622-60 tire in the rear. During setup, I found that a 622-64 tire fit fine. A bit snug but not problematically so. I was being pretty conservative in my design and this is where I can find out what works. The change in tire size alters the angles 0.2 degrees.

The top and down tubes are worth mentioning. The down tube is a strange one. It’s a Reynolds 853 BX2850, 1.75″ diameter and 800mm long. It just fit into my design with a millimeter to spare. Seriously, why are all these tubes so short?! The top tube is a PVD Super-Ultra, 1.125″. What’s crazy here is that the center to center distance of that tube in this frame is 706mm, the longest I’ve ever used in a bike and probably longer than anyone really.

The PVD Sidewinder caliper mount shows up again. This frame can use flat mount calipers for rotor sizes from 140mm to 180mm. Post mount calipers from 160mm to 180mm. This let’s the bike skinny down to extra lean builds and full heavy. Right now it is full heavy, 180mm post mount four piston calipers.

My wife chose the RAL6005 Moss Green color to go with the silver Pike fork. I approved that and it does look great. I’m definitely happy with this. I think that it’s pretty much RAL ‘British Racing Green’, the legendary color of fast.

I can’t help but give a shout out to the wild titanium rotor lockrings from my buddy Josh Ogle. I don’t have much bling on my bike but these are always exciting to look at.

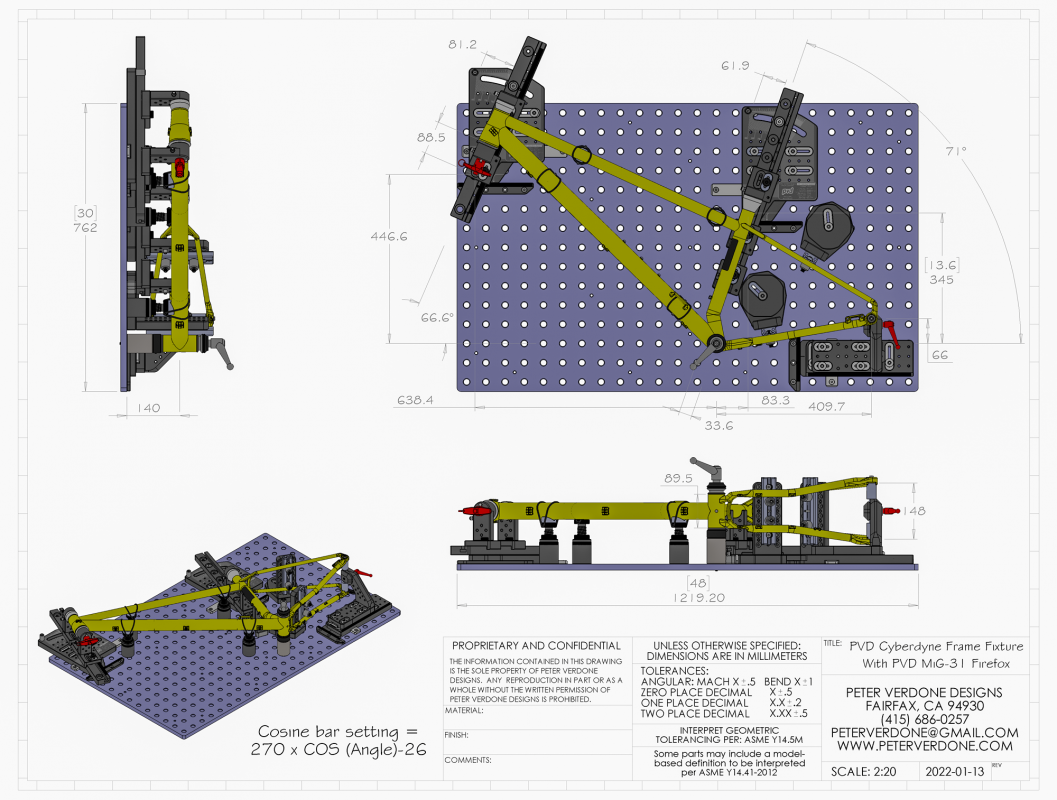

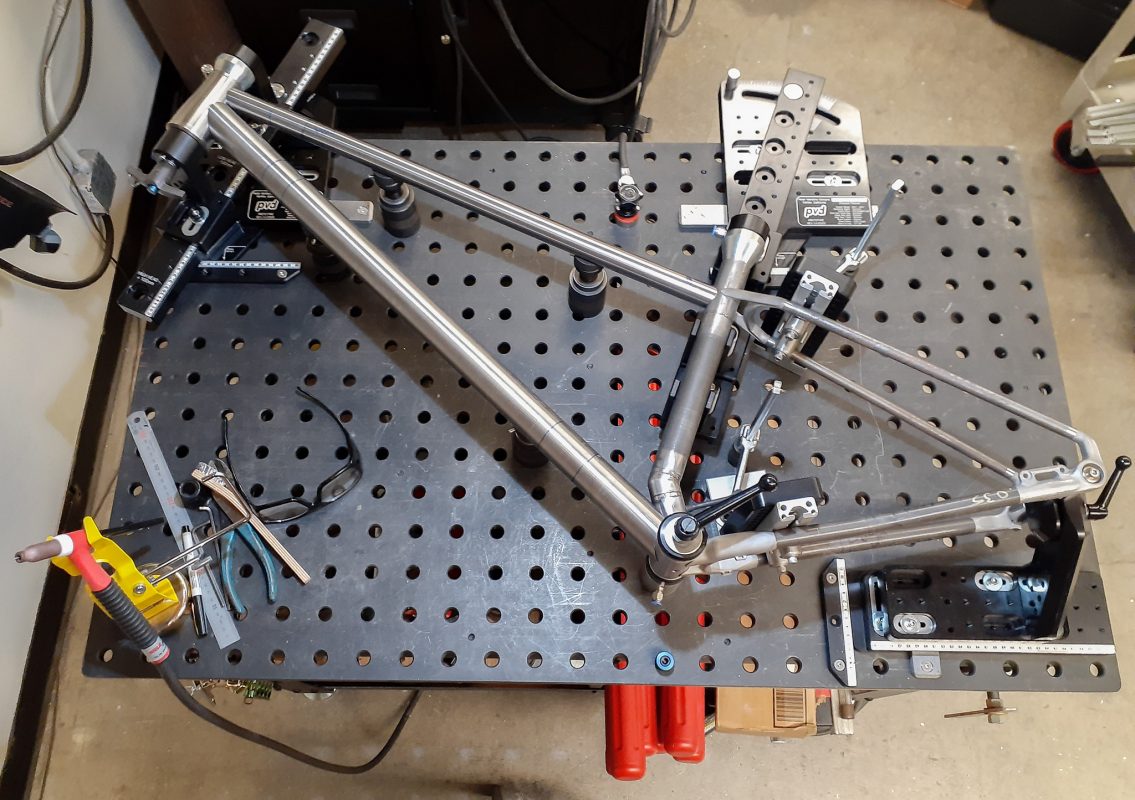

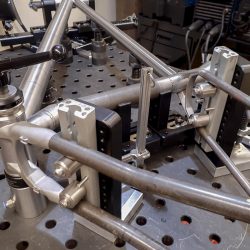

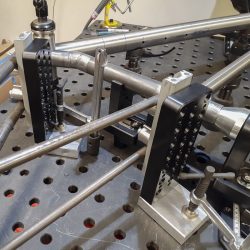

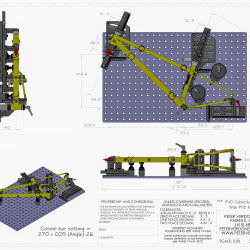

In fabricating this bike, I decided to change the rear end spacer holders in the PVD Cyberdyne frame fixture. The previous system was pretty cool but took up a lot of table space. I wanted to get my spacers close to the area of the stays that has a critical need for centering. So, by going to a clamped down holder, I gained much more room to get into this area. I love how quick and easy it is to make improvements and changes in this system.

Davey Simon came by my home shop while I was assembling the Firefox on Friday night before Saturday’s ride. We shot the shit about his life in Seattle and flying jet planes. He took some selfies. I look old and fat here…I am. Still, this snap captures the mood of a project coming to an end. An exhausted march of death to the end. I thought it was funny.

Ride #1, 2022-01-29 – Two things were clear on this ride. The Firefox was amazing & I was not. The bike did all the stuff. I kept looking for problems with the fit and function but I really couldn’t find any. I lowered the handlebars 5mm some from the initial (as photographed) position. It made the bike feel really aggressive in a good way, like it wanted to climb! Hard!

Drivetrain was solid. Rear end flawless. Fit great.

I was concerned that the saddle wouldn’t be far enough forward in my design to really advantage climbing. Saddle fore/aft is a delicate balance of climbing performance while keeping all day traversing comfort. Here, following too closely to the rigid bikes would be a mistake as the fork will extend during climbing. In a static state the Firefox is 74.6-74.8 degrees depending on rear tire choice. For this old fat guy, that’s about as much as I can handle and I’m glad I didn’t go much further. A strong young racer could easily do more.

The air pressure in the 150mm Pike fork started at 90 psi but was lowered to 85psi which was a bit better. Compared to the 180mm ZEB that I’ve otherwise used on trail, this fork is firm. I might get into some damper modifications to squeeze some ‘plush’ feel from it. Maybe I’ll know more for this in another few rides. I haven’t done anything else with the fork yet and don’t even know how many volume adjusters are in place. I will focus on the fork in the upcoming week.

The build of the bike is certainly on the ‘trail’ side of cross country. In the summer, I’ll try some fancy fast tires on it. For now, real knobs are a better choice. The 36 tooth chainring is really about screaming out loud “THIS IS AN XC BIKE!”. While that works well on the TIE Advanced X1, I’m not sure it’s going to work for me here. I’ll run it until I can’t. Then shift (ha!) to a 34 tooth.

The bad strap worked out so much better than previous iterations. It was easier to work around on the trail and super solid. Like, WOW! This is what’s up. Locked and loaded.

In contrast to the bike, I was garbage. I had no strength. I was doing stupid things. I was pushing too hard to keep in the front of a group. My heartrate was popping. This can often happen when I’m analyzing too much on a ride but this was something else. I just need to caulk today up as worthless.

I ride again tomorrow. Hopefully my body works.

Ride #2-4, 2022-02-05 – As I get used to the bike it gets faster, or I get faster on it. It’s a nice mix of hard changing DH and ‘makes you want to smash’ climbing. Along with a couple of loops around Tamarancho, I’ve taken it on Tamalpa Trail, 999esses, and Hobo. I did notice it working a lot better than the Warbird on the tight switchbacks on upper Tamalpa. I don’t feel that I’ve got the bike up to speed yet. It’s mostly me feeling old and shitty and also getting used to what I can get away with on the 150mm fork. It takes some time to convert from full rigid mode to hardtail mode.

I’ve changed the fork to 80psi and two volume spacers. I need to look up how much more it can take but I’m pretty close.

The bike feels softer in the rear than other bikes. Just, more comfortable. When I did a ton of climbing on Tam, my knees felt a bit better because of the crank width. It was noticeable but mostly later in the ride.