I finally mounted the new Meade LX600 telescope to the newly fabricated pedestal in our observatory at work. This, just as the semester is starting and on the day of a major eclipse in North America.

It looks so nice. It’s another great upgrade for the observatory. I now have just one last scope to isolate. The state of the whole operation is much nicer than when I started here. I’ve improved a few things on this pedestal over the last pedestal. Essentially, better methods and the nice addition of water cut instead of plasma cut parts.

Here is the old pedestal and scope. It was so flexy and and connected directly to the building with no insulation:

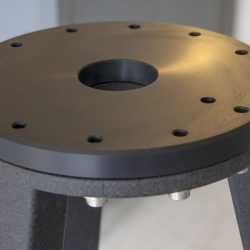

Here is the new. Fully insulated from high frequency noise in the building. Super solid.:

I had to cut the giant studs off and grind the surface smooth.:

I also found some sandbags in the base of the old pedestal. Probably a late addition to stop some of the noise. It hadn’t worked well.

TIG welding the new pedestal was nice. Thick mild steel is so easy to work with compared to the thin cro-moly I use on bicycles. No fuss. No hassle. Just smooth creamy welds. The best part is, even without a great welding table or fixture system, I was able to weld the structure within 0.1 degrees from parallel. Sick.

Everything bolted together as planned and the sliding roof clears the scope.

Crinkle coat black. OG.