You know how you’ve been doing something for a long time? Like, a really, really long time. I’ve been doing skateboards for that long. I’ve wanted a tool since I started. I finally made it. It’s a drilling fixture for baseplate holes in skate decks. I’ve actually needed this several times in the past few years as I tend to want board shapes that don’t conform to what kids are looking for. For an upcoming project, a juvenile 6.25″ skateboard with a 12″ ‘wheelbase’, I decided I’d finally make what I’ve always wanted. It will produce wheelbases (according to typical skate measures) of up to 20″.

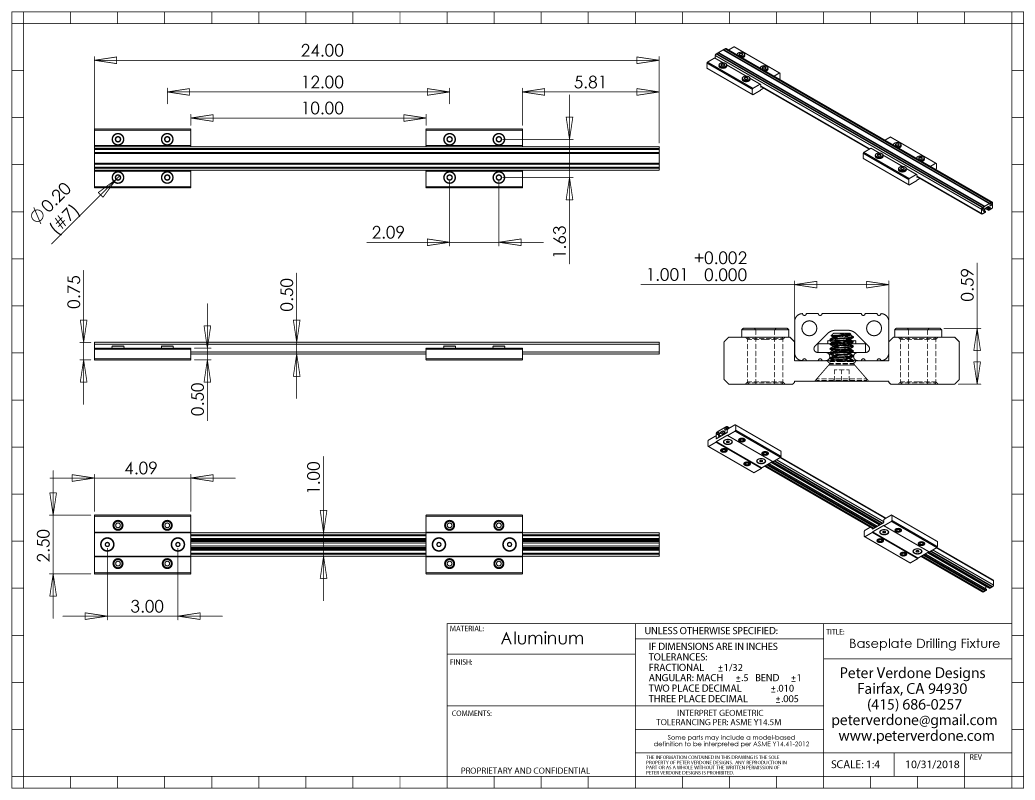

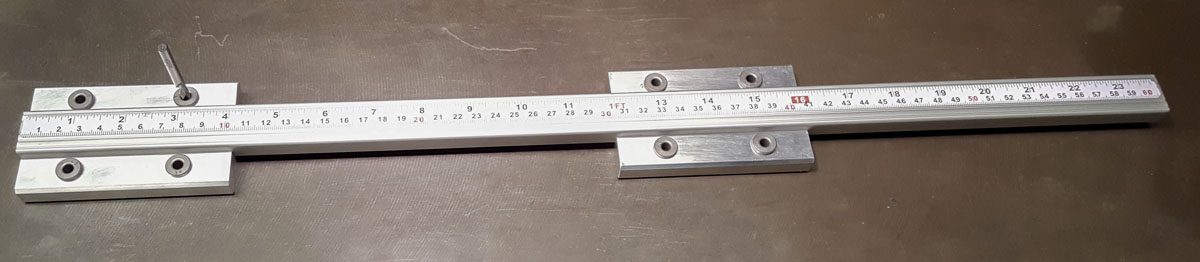

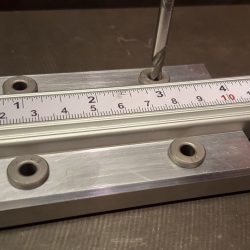

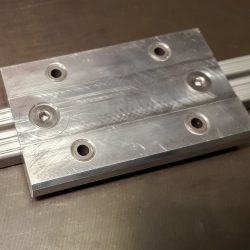

I wanted to engineer this well, also. It uses very inexpensive parts, it’s easy to adjust, it’s easy to make, it’s easy to use. The only real thing that had been holding me back from doing this before is the cost of the drill bushings. These are Press-Fit Drill Bushing with Head for #7, 0.201″, drill. This even as you will probably want to use a #11 (0.191″) stub drill for your work. They cost $9.69 each from McMaster (#8492A101) and I needed 8 of these. I figured I’m old enough that I should just man up and do it right, finally.

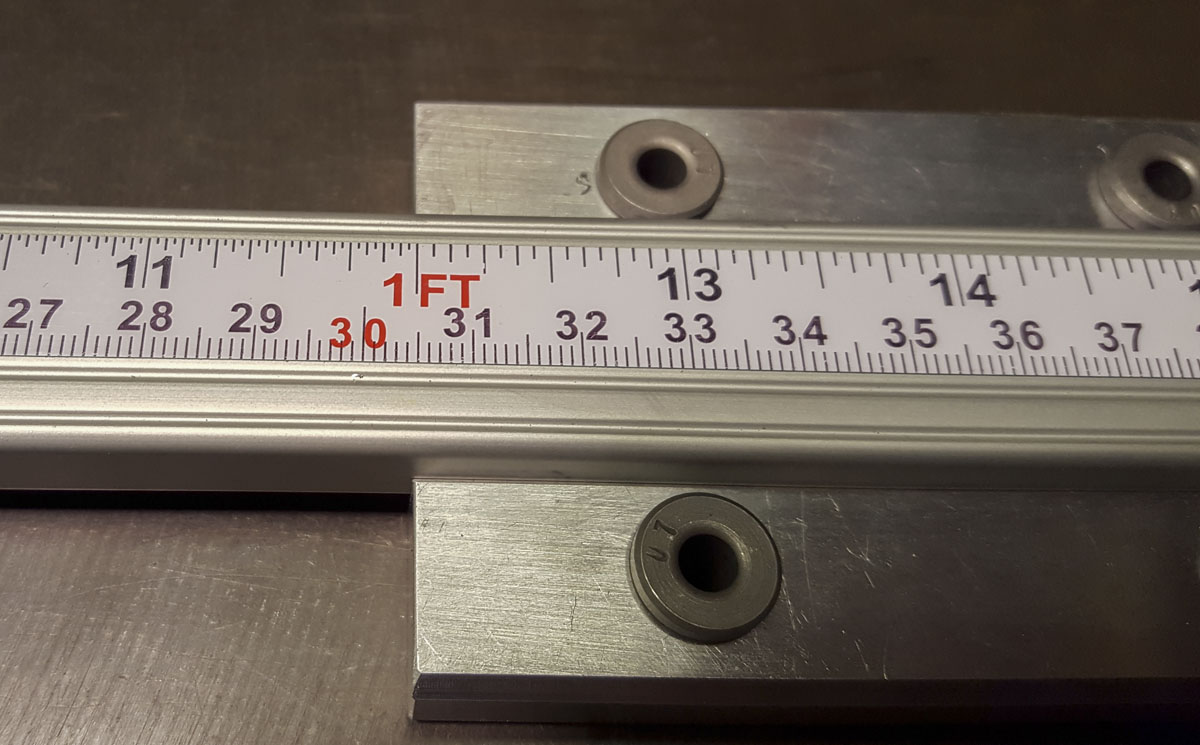

80/20 #1050, 1.00” X 0.50” T-Slotted Profile makes the beam. Some 1/2″ adhesive Imperial/Metric rule makes setup easy. Tnuts has a nice selection of low cost and preferred t-nuts for the 10 Series extrusion.

When cutting the blocks, some additional material is removed where they seat against the deck to help them fit solid, regardless of rocker and concave. Not super awesomely done but a little help goes a long way.

Now I can move forward with the project and cut the deck out.

Today is Halloween. It’s the birthday of an old friend of mine, Ram Hannan. I’ve seen on his Instagram that he’s been stoked on trick skating again at the age of 46. I hope the old man survives. Happy birthday, bro.