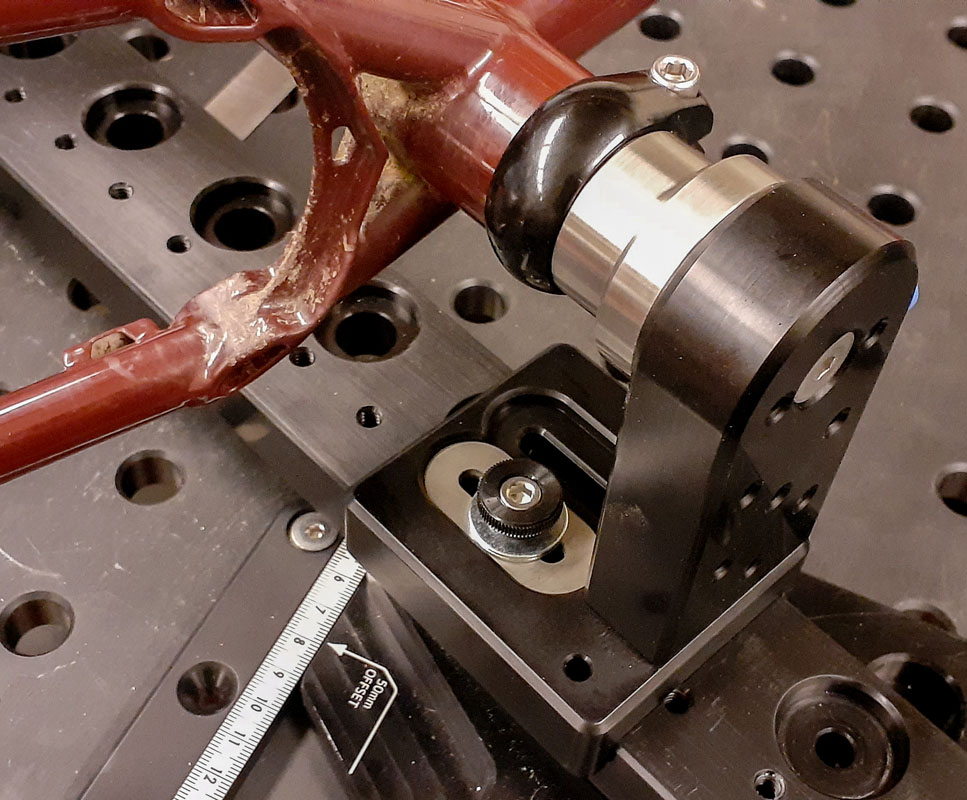

Here’s a cool modification to the Cyberdyne frame fixture. While I worked to make the fixture as best I could in the initial round, I wasn’t going to be able to do everything I wanted as the project would never end. Now, when I can focus on just finer aspects of the use and refinement, I can take on those details.

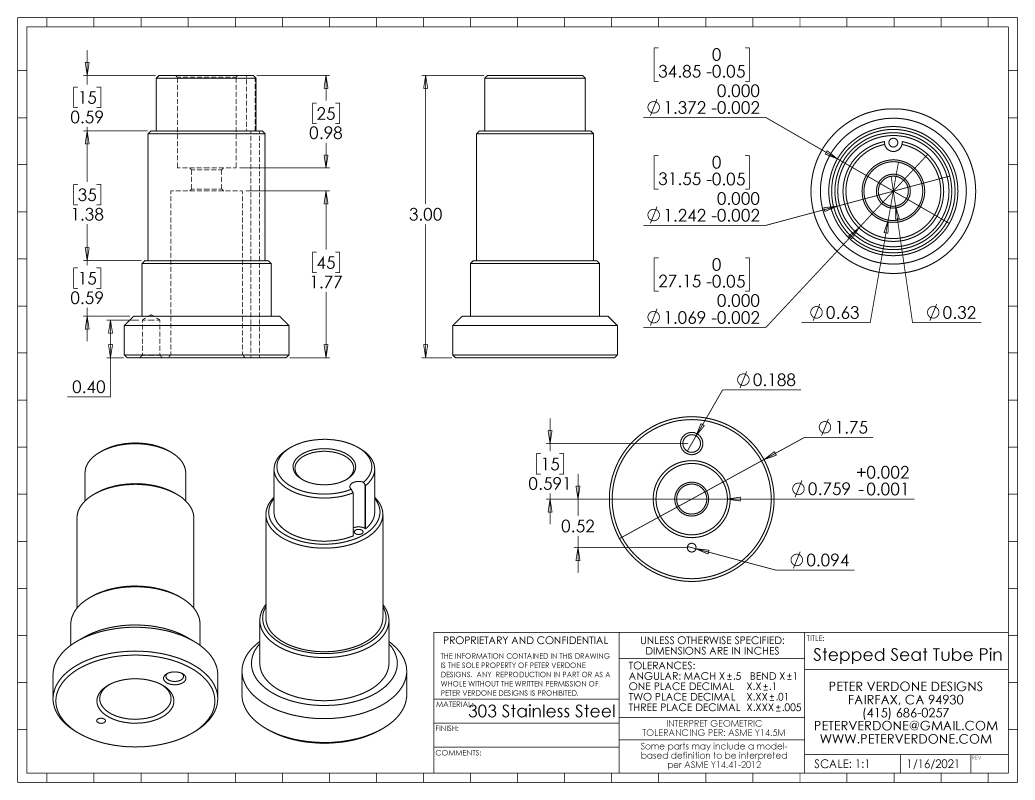

This is a cylindrical post for location of a seat tube, segmented seat tube or for reloading welded frames (slight distortion) into the fixture. Segmented seat tubes need supports without axial pressure but there are times that those aren’t able to be used and this can help. Also, if a frame has been painted, the increased diameter of the tube plus paint won’t fit the holders. Something was needed as an improvement or option from the cone support.

There are good reasons to use a cone for locating tubes in a fixture. They self center and will fit any tube within their range. They are bad for everything else. They need significant pressure to hold fast and they allow significant misalignment without notice. In some cases, a cylinder may be better. They locate precisely if they are cut precisely. They work against misalignment. No pressure is needed to locate a tube axially or radially. They can also handle significant distortion force against them.

I can use the binder of a finished frame with a split top to grab the fixture post then float the adjustments into place of actual rather than theoretical placement. This makes for solid support during repair or measurement a breeze. This can be difficult with a cone.

The fixture post has three diameters, 27.2mm, 31.6mm, and 34.9mm, the most useful sizes in the current era. The 31.6mm section is the longest at 35mm as that is where the real work is happening. The other two are 15mm long, just enough to get me out of jail when the time comes.

It was tricky to make the argon plumbing work correctly with the initial parts but I figured it out and didn’t break a drill making it.

It looks so much nicer IRL than in the CAD. Super cool.