We all think of custom differently. I like to take things a lot further than what you see in magazines. Spending money on retail crap isn’t custom as I see things, it’s consumption. Custom should be at your own hands not your pocketbook. It should be about taking risks, to show your style and flair. This, even if others hate it.

I’ve been doing a lot of laser engraving lately for a side hustle. High tech markings for satellite and autonomous aviation parts. The bay area has become and aviation hub and it’s become common to see Space X parts flowing through friends shops. I’m also getting to work on parts that will go to space which is very cool.

This has put me in front of the engraver more than I have been for a while. And pushing my thoughts in that direction.

In the years since getting my engraver, I’ve become better at making great marks and have improved my tooling considerably. I have wanted to update a few bicycle parts with a new eye.

Getting a new tool puts you to work using it ways you aren’t used to. You need to try a few things to see what sticks. Sometimes, you go too far. Other times, not far enough. Things can look messy or intentional or cluttered. Over time, we learn what to do for that nice touch.

The PVD valve caps needed a larger logo and a less cluttered look. I’d run out of the older ones and a new batch will let me drop them onto unsuspecting bikes.

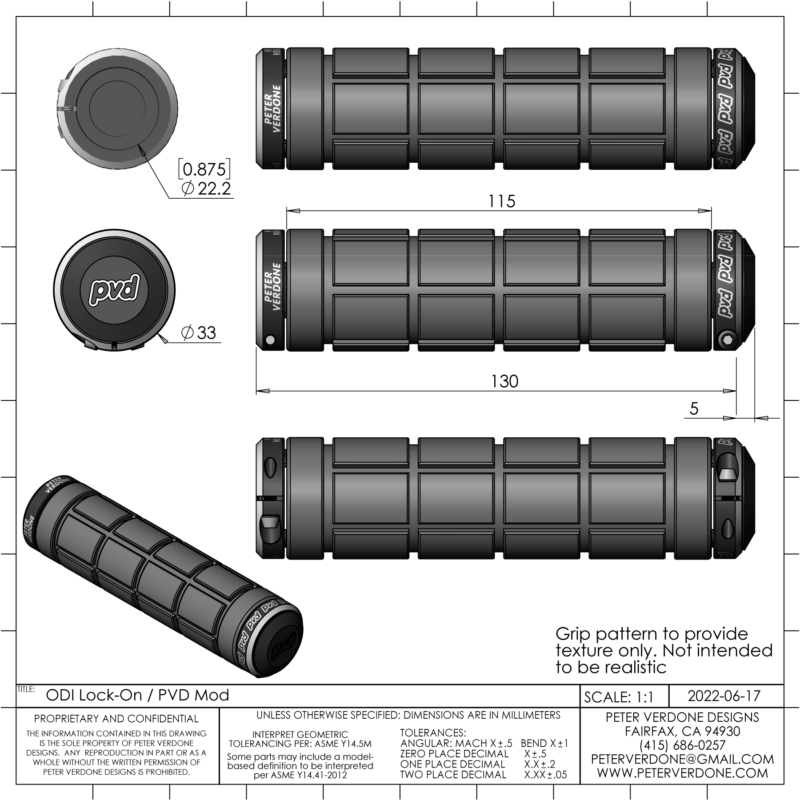

Handgrip clamps were also addressed. Again, less cluttered and bolder logo. Now I’ve added rider names to the inside clamp. It looks nice. On the bike the markings look good.

The carful observer will see that I’ve chamfered the edge of the clamp and reduced the diameter and chamfered the rub disc. I’ve been doing this to lock on grips for the past 15 years or so. This makes the grip more slippery when I rub against tree and rock. It also minimized glove cutting burrs that will form over time. I tend to roll the heel of my hand over the grip when riding and this softens a hot spot. This mod is huge and one that I don’t see others doing.

I also swap out the stock screw as they rust after a bit of use. The stainless steel screw that I use is also chamfered to reduce protrusion into the grip area. A nicer feel and less to rip at.

I’ve been doing these kinds of mods since the mid-nineties. A tricky rock hop on Tenderfoot trail in Mill Valley caused bars to rub hard against a rock wall. I wanted more slip. I’d hammer delrin plugs into the end of bars. It helped.

This customizing isn’t just marking. It’s practical and performance oriented. Recently, a new set of pedals meant another run of sharp spikes. This makes the pedal more grippy with far less pressure. This really helps pedal control for those of us with less gifted skills. These take a lot of work to do but I feel it’s worth it.