It’s finally time for this problem to be solved. I’ve been wanting this for a very long time! Now testing can begin without constraints.

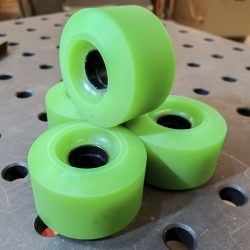

I’ve been contending with the availability of wheels that conform to the needs of my skateboard project. I need tall and soft wheels for ease of travel over rough road but light and narrow to keep the feel of the board light and lively. A very wide wheel carries significant weight and makes for a lot of turning friction. That’s not what I want.

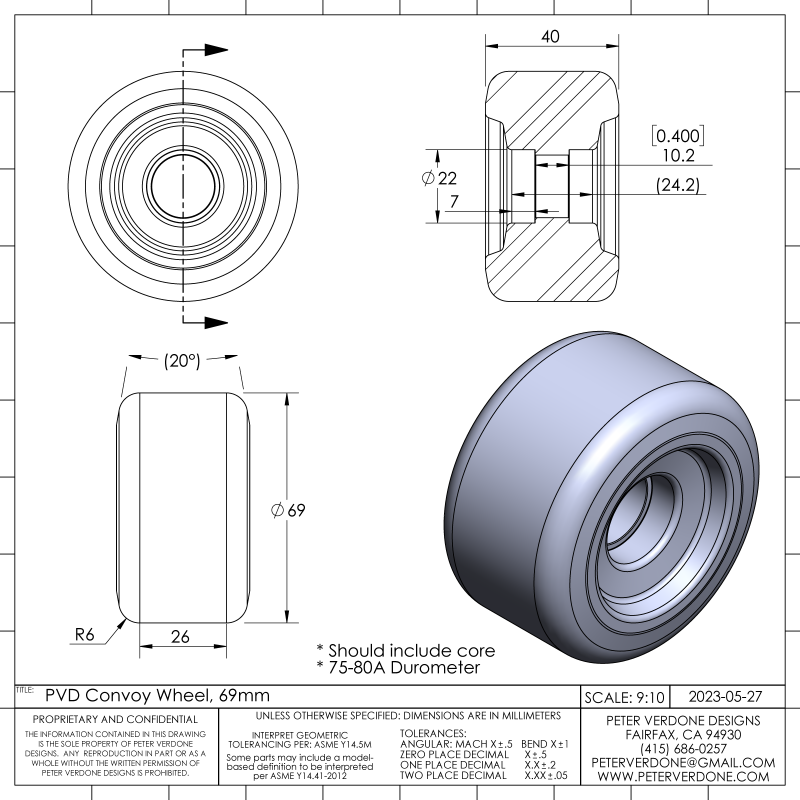

Most wheels in the larger diameters that I need, 66-70mm, are sold for novelty ‘longboards’, sliding rigs, or downhill racing setups. In those cases, the aspect ratio of the wheel is wider than optimal for simple travel. This helps support the wheel when sliding and increases the contact patch for traction. In my case, I need a taller aspect ratio, I’m not looking to do slides or anything but cover ground.

To compare with bicycles, I’m trying to build a road bike, not a BMX bike….but skateboards. It’s not for smashing around and doing tricks and such. It’s for covering ground effortlessly and efficiently while feeling very nice.

I’m currently not prepared to pour my own wheels. Sure, getting molds cut is pretty easy. It’s not a complex model to produce and I have a few friends with very fancy tools that would make quick work of the task. It’s really the R&D of the polymer that doesn’t excite me now. Another time, but not now.

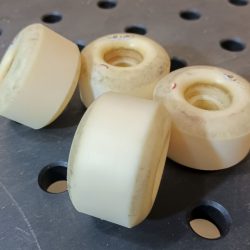

Anyone that has tried to modify skate wheels has had to contend with some brutal truths. Skate wheels are made of some very high quality urethane that is extremely durable and tear resistant. That’s what we want in a skate wheel, durability. The problem is that this also makes cutting them very difficult. For skatepark and flipper wheels, that are between 95-100 Shore A, some reasonable measures can be taken to cut them on a lathe. For the soft wheels that I’m looking for, 70-80 Shore A, it’s extremely challenging.

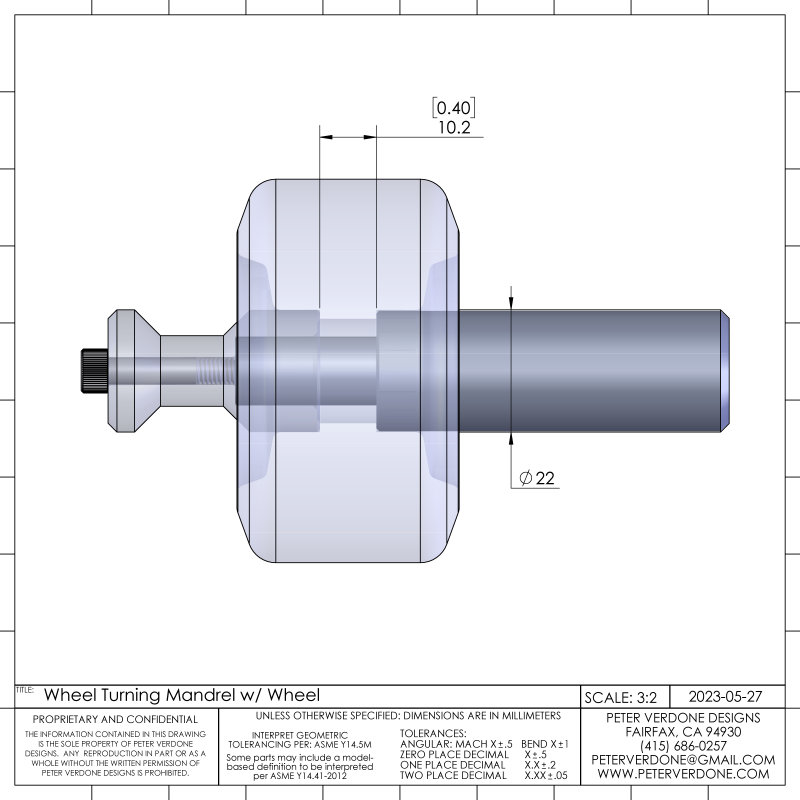

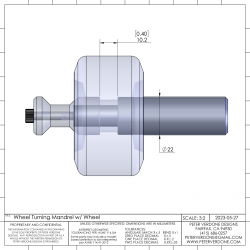

About 20 years ago, I’d made a nice 22mm (608 bearing is 22x8x7) mandrel specifically for cutting skate wheels on the Hardinge HLV-H collet lathe. I’d cut my skatepark wheels to be nice and round again after lots of riding turned them into eggs. The wheels got smaller but being cut rounder and more concentric than stock was super smooth in the skatepark.

Back then, I was able to grind a small HSS bit to a profile to cut the hard wheels. The tool needs an insane top rake and also has to be at the pinnacle of sharpness, like a knife or utility blade. When turning lots of used wheels, the sharpness of HSS is degraded (because of the imbedded grit) and cutting eventually turns into a mess. Still, this was a useful tool.

For cutting the very soft wheels, we need to seriously step up our game.

Abrasive disks could be used on the wheel while it spins in the lathe. This will remove material smoothly. In that case, an angle grinder is fit with a sanding disc in the range of 80-120 grit and is applied to the wheel while it’s spinning. I’m sure a tool post to hold the grinder can be made for precise cuts but this is outside the scope of this post. I don’t go this route as I want more control and quality in my work.

Using the lathe and after making an arbor, the next move for machining very soft wheels is to freeze them. Placing the wheels into a cooler along with a few blocks frozen CO2 ( dry ice) will do the trick. Dry ice is quite cold, −78.5 °C or −109.2 °F. This is much colder than frozen H2O (water) (0 °C).

Dry ice can be obtained in many super markets and most welding supply stores. I work in the College of Science and Engineering at San Francisco State University, so I can just go upstairs and get bricks from the Chemistry stockroom. Hell, I could easily obtain liquid nitrogen (-196 °C) or even liquid helium (-269 °C) from the stockroom but the safety concerns in working with that aren’t practical. If you are at a school or science type operation, ask around and see what might be on hand.

Give the wheels some time in the cooler. I’ve found that 1.5-2 hours up against the dry ice block will produce a (temporarily) very hard wheel. Even with this freezing, it may be necessary to break up the machining of the wheels into a few steps with 15 minutes of freezing in between as the wheels will get warmer as the are cut. The softer the wheels, the more this will be needed.

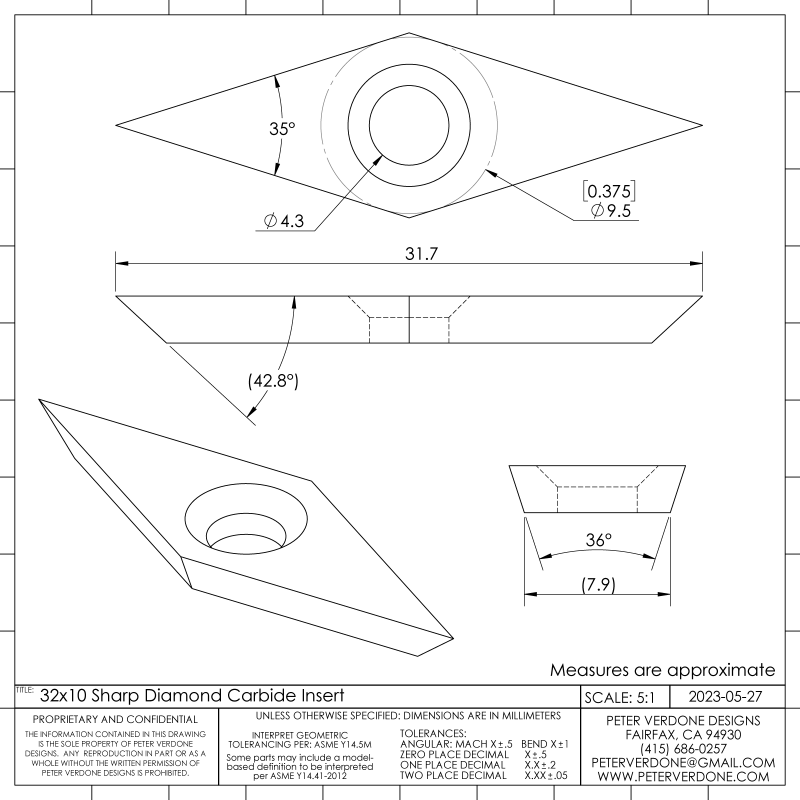

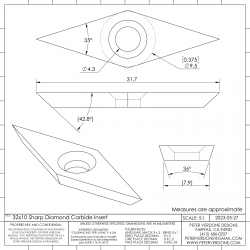

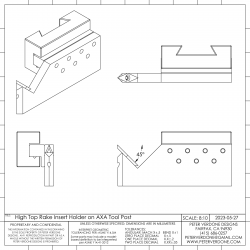

The second issue is a bit more challenging, the tool. Traditional metal working lathe tooling is simply not sharp enough to do this job. I did a bit of research and scouring of the internet to figure this out. I finally came upon the right thing. In the woodworking world, there are tools for spinning wood on lathes. Long arms that are placed over a bar and moved by hand to cut organic shapes. They are extremely sharp as they are cutting such soft material. These can be sourced with carbide inserts. I chose one of those inserts in particular, the 32×10 sharp diamond. These cost about $5.50 each but can be as low as $4.00 each in packs of 10. They are wildly sharp and hard. At the point, they have an approximately 42° end relief angle. There are other shapes available. I think that a diamond with a rounded nose might be good for cutting hard flipper wheels.

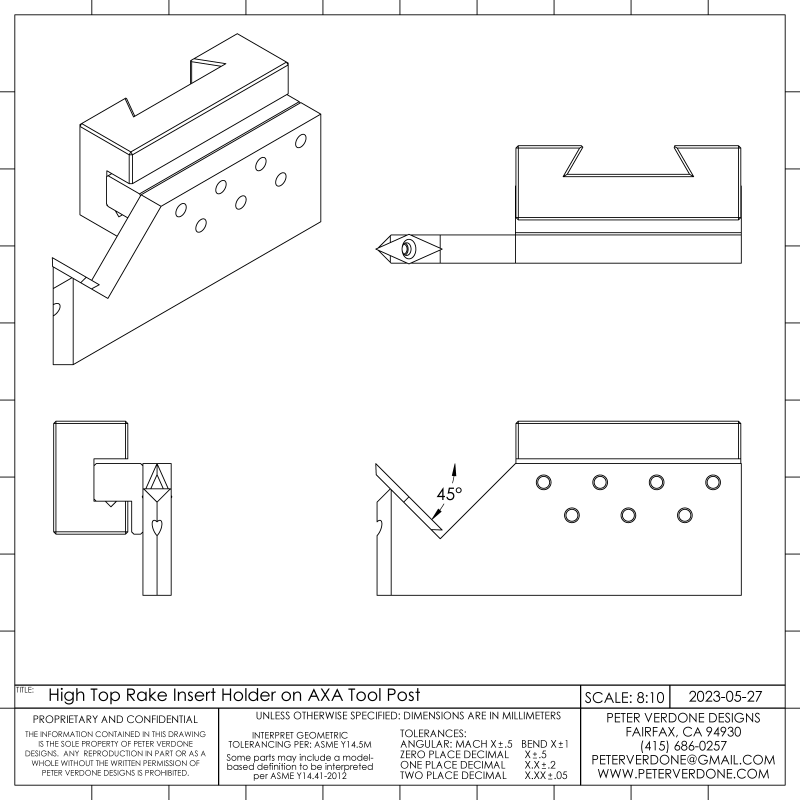

Now, to turn that 42.8° end relief angle into to top rake. This requires a toolholder that will set the insert at 45° relative to the tool post. I made this tool in two pieces so that I’d have some modularity to play with. There may be better ways to make all this happen but I got something done and moved forward.

The tool needs to be aligned so that the point is leading the cut as much as possible. This reduces the loading in the cut area and helps the polymer peal away from itself. This is important. Any loading in the wrong direction will just push the material around and ruin the cut.

I may make another tool using 30×12×1.5mm-35° carbide cutters knives blades. This could allow me to do a single face cut at once without the need to single point. The top rake would end up being 10° less than what I’m using, but with little room for the urethane to escape, a face cut could work well.

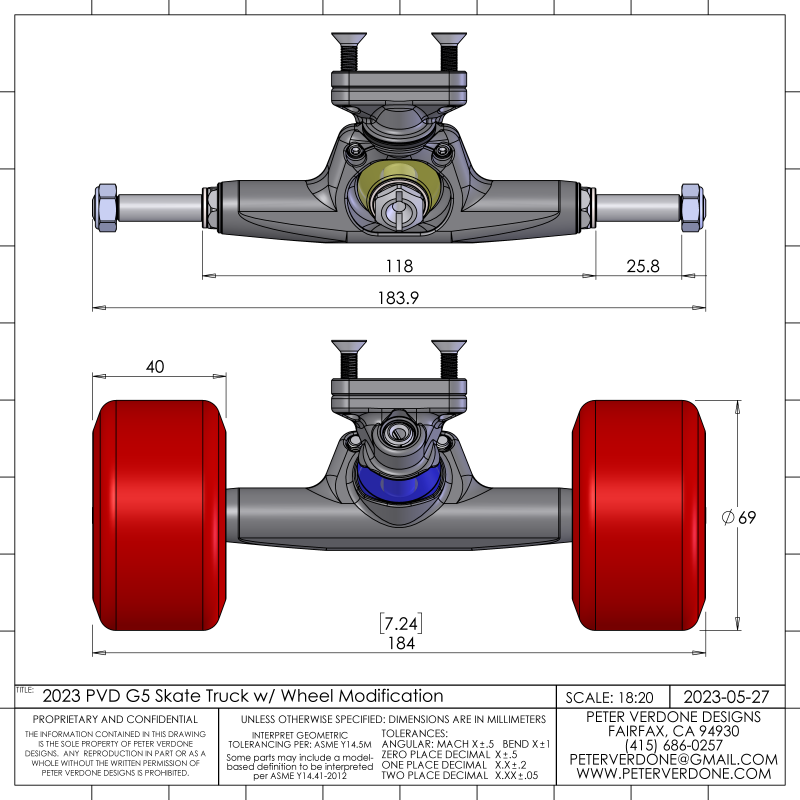

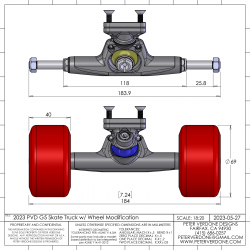

Now that I had narrower wheels, I needed an 8mm wider hanger. I had some wider 118mm PVD G5 hangers produced in my last round of prints for the bicycle I’m currently building. This extended the 40mm wheels to 184mm OAW as is needed for the test board.

As I dream of just the right wheel to actually mold someday, I can now prototype some approximate shapes. I’ve drawn up the rough shape of what I’m thinking. This is all very exciting.