I finally got around to modifying the bolt knob on the bolt of my Remington 700 bolt rifle. I like shooting the rifle a lot. It’s nice and light and accurate. It’s cheap to shoot .223″ or 5.56mm through it and it shoots straight. I could shoot it all day and have fun.

Over the course of hours, though, the small grooved knob provided originally causes sore fingers. This is easy to understand. The rifle was designed and intended as a hunting rifle that wouldn’t see too many rounds going through it in a day. The knob needed to be low profile during carry and easy to action with gloves on. Not the same as sitting easy and shooting a few hundred rounds on a warm day. Simple.

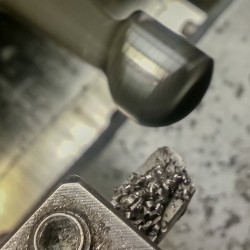

The fix that many folks do is to install a new knob. Remington doesn’t make this easy. The part needs to be cut at a very fancy angle on a lathe and threaded to 5/16-24. Then there are all types of knobs available.

To hold the bolt, I was originally going to make a holder. Over time, this project sat. I decided to just pony up for a holder from Pacific Tool & Gauge. They make great stuff for gunsmithing. I just purchased the Phase I Bolt Handle Knob Removal Jig – Angled Handle. That done, I just needed to figure out how to align the handle for cutting. I figured out a way to center it on the free axis. The other axis didn’t provide any space for that. Maybe I will modify the tool next time I do this.

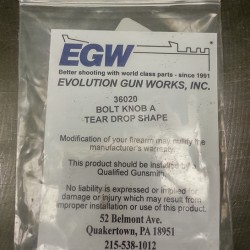

I got a nice simple teardrop knob from Evolution Gun Works. The Bolt Knob A-Solid Tear Drop Shape. I wasn’t looking for anything fancy. Just easy on the hands and eyes.

Once I got home and installed the bolt into the rifle, I was a little let down. I hadn’t cut any more from the length of the arm than I needed to get the job done. The knob was a bit clunky and in the way. Granted, I haven’t benched the rifle yet but it is far longer than I need. I should have cut another 3/8 – 1/2″ into the arm. That would have minimized the protrusion.

I’ll make an attempt at jumping into the thread again on Thursday to see if I can get this done.