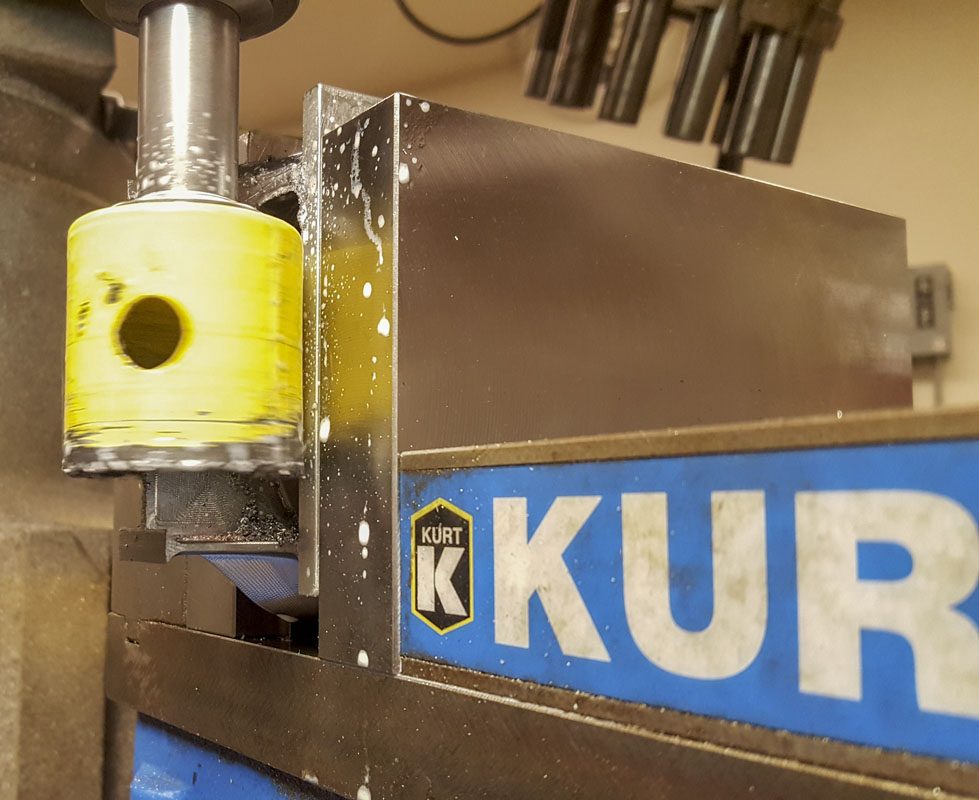

I’ve needed this tool for a long time. I knew I did but never really went down the road to it. Moving a nice Kurt D688 vise to my shop from another had me looking at my setup.

Much of this late winter has been devoted to improving my CAD models and tooling. Much of the design is around 1/2″ solid aluminum optical breadboard. I started buying this material from a low cost supplier but have found that the product from Newport is much more dependable and accurate. Well worth the extra cost.

I needed this tool to integrate that breadboard to the mill for machining use as well as hold some tricky parts.

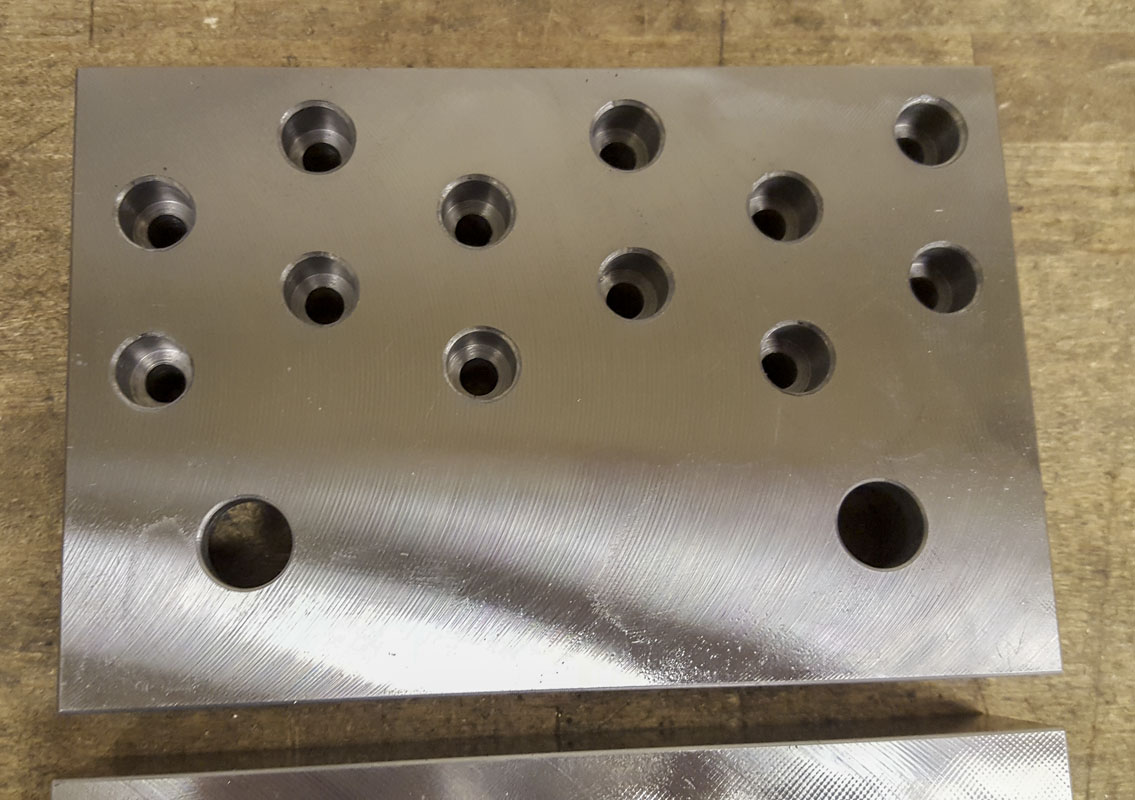

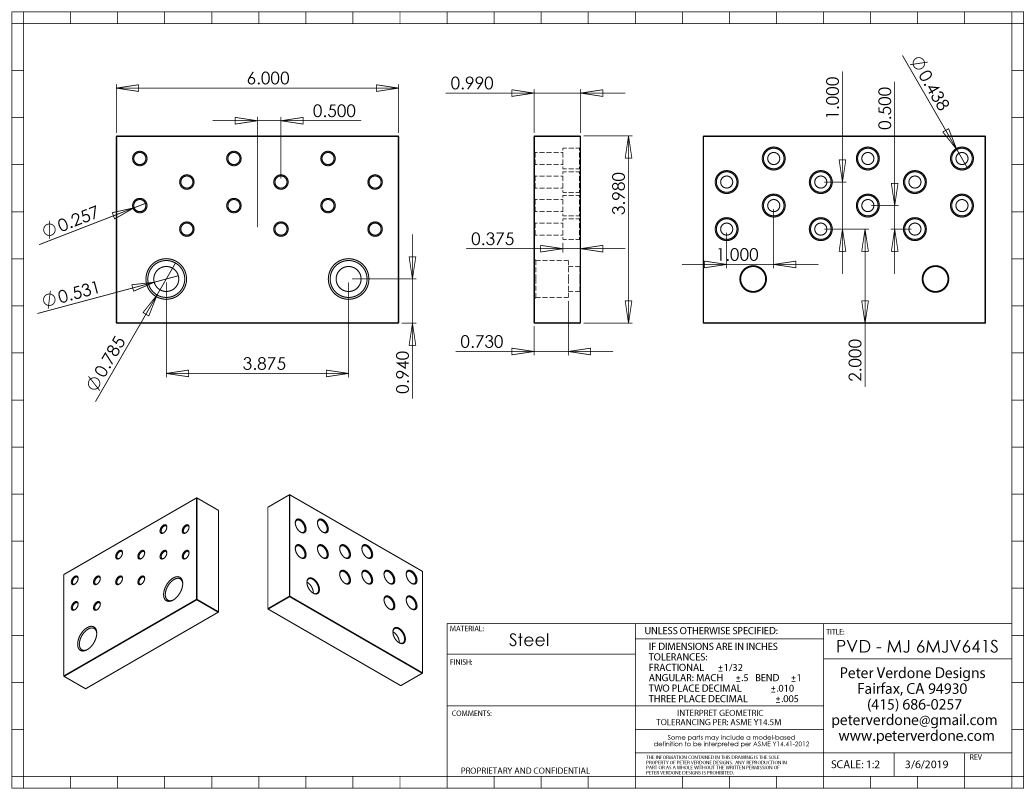

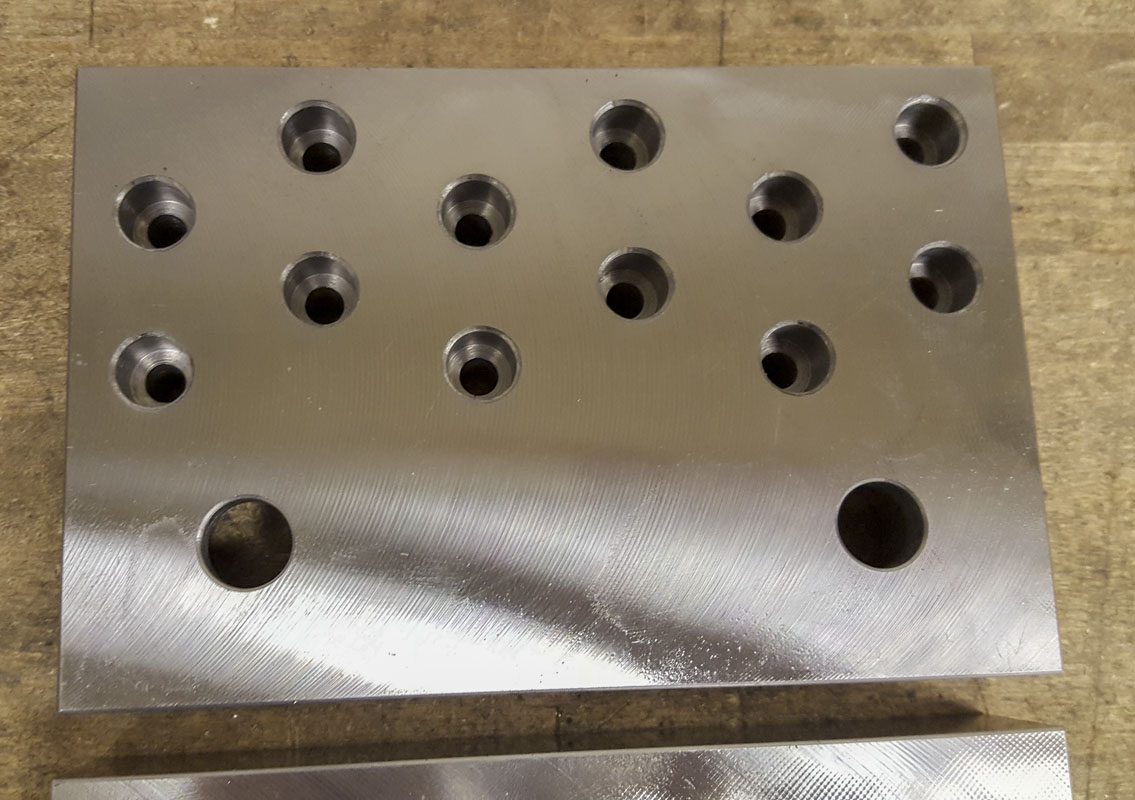

Here, 4″ tall steel vise jaws from MonsterJaws (6MJV641S) for 6″ Kurt and the like. The jaws only cost about $50 and are well worth it. I wish they were offered at 6″ tall x 8″ wide for 6″ vises with a 1/4-20 pattern as well as a countersunk clearance pattern (on the same plate?!). That would be a super useful tool for a lot of folks!

But I don’t stop with wishes! I added the breadboard mount and I now have a very rigid base to mount all sorts of tricky jobs to the vertical mill.

Mitering chainstay yokes, for example, is now so much cleaner and smoother than the old rickety way I was doing the job.

Not to mention my new chain and seatstay tooling. So much more rigid than a lot of other setups outside of a horizontal mill setup.

I encourage anyone working with bicycle and oddball setups on a vertical mill to get setup like this. I really regret not doing this a long long time ago.