A few years ago, I got a Whiskey No. 9 fork to put on a bike. It was one of the few options for that type of fork at the time. It has proven to be a pretty horrible fork. Not only is it stiffer than a girder and painful to ride but the cable routing is insanely bad, like wtf bad. Since then, I’ve picked up a couple more cheap Chinese forks. They ride better than the Whiskey fork but all share the horrible hose routing. I simply can’t understand what these people were thinking.

I see a lot of bicycles and forks, some very fancy on the floor of NAHBS, with the most atrocious cable routing. It’s as if they had never learned to put a bicycle together before going into business building them. I see routing that produces mechanical problems, opens housing at the stays for contaminates, or routes in the wrong directions. This isn’t restricted to the craft frame market. Try to put an Ibis together and you will live in a special kind of hell trying to route cables. It’s fucking crazy. Companies that spend months dialing in mold shapes and specifying orders only to spend less than 5 minutes on cables. It’s a crazy industry.

These days, we often have brake hose routing and dropper hose/cable routing that often needs to be modified for maximum performance because the bike really wasn’t ready for prime time. I can often wait until a frame is getting repainted to redo the braze-ons. Often though, we have a bare carbon fork or nicely finished mass market frame that has to get routing changes. We need options.

A couple of simple options exist to do a nice job with this problem that don’t require a repaint of the frame and still end up looking very nice.

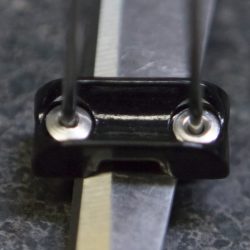

Nova Cycle offer two aluminum hydro straddles, a anodized rivet-type and a weld/epoxy type. Many other suppliers of these parts exist and may be closer or cheaper for you to buy from. There are also other designs that may be just right for you.

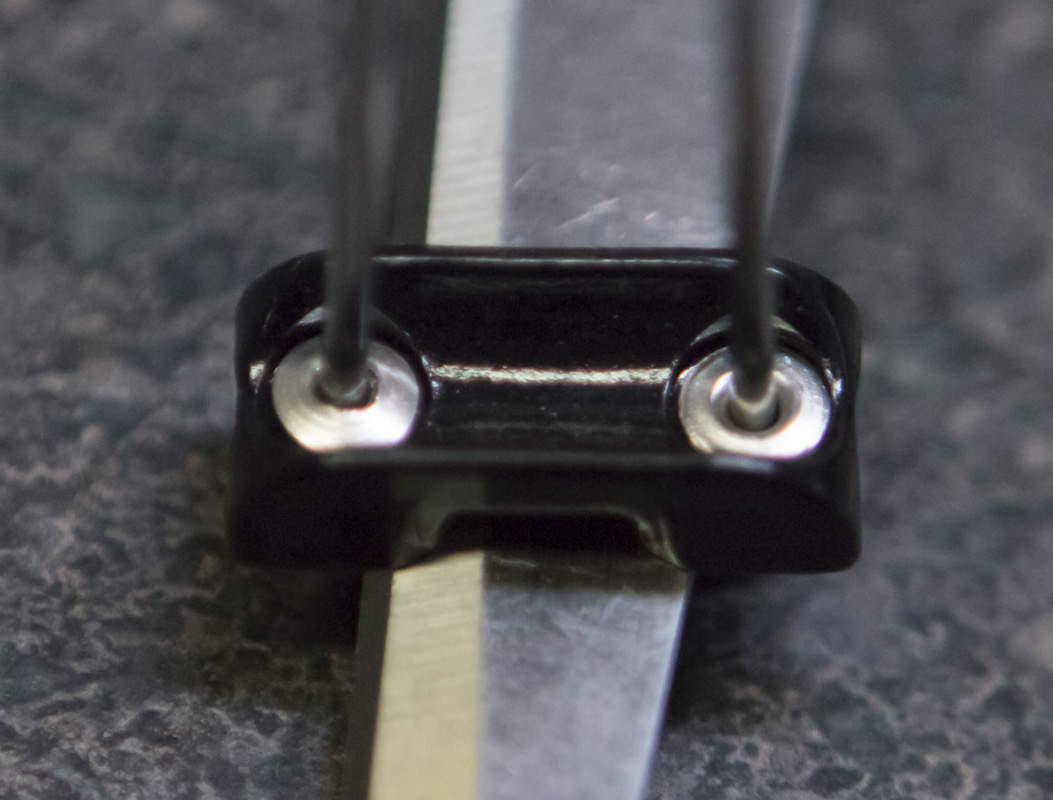

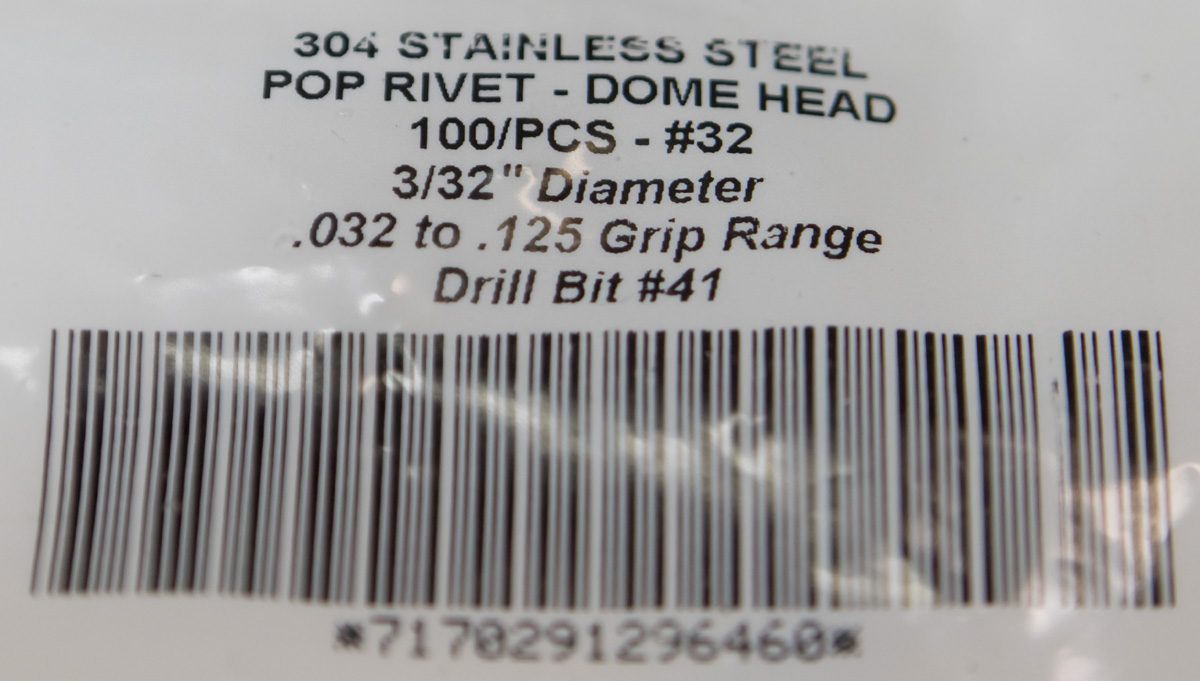

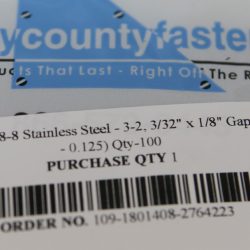

To use the rivet type, simply drill a couple of holes and rivet into place. Measure twice and drill once. This works well in locations that allow for safe drilling and are well thought out. I suggest stainless steel rivets.

The other option is to epoxy the rivet or weld/epoxy type onto the frame or fork. This is preferred when structural concerns override convenience. They can also be removed with minimal effect on the paint. Some yes, but care will reduce the damage.

I used 3M Scotch-weld DP 420 Black (2:1). (PDS). It’s baller stuff and used to hold many carbon frames together. Keeping a heat gun handy will speed up the cure time.

An Applicator is needed with high end epoxies. Any Sulzer Mixpac MA50 type dispenser will be wise to buy. MIXPAC A50 Sulzer MIXPAC™ B-system dispenser . The 3M EPX Plus II Manual Applicator is just that. But the generic MIXPAC DMA 51-00-10 is much cheaper.

Plunger 3M 37ml offset cartridges 2:1, 62-9170-9921-0 (3m) PLA 050-02-3M (MP)

Plunger 1:1, 62-9170-9911-1 (3m) , PLA 051-01 (MP)

Plunger 10:1, 62-9170-9910-4 (3m), PLA 050-10 (MP)

Plunger 2:1, PLA 050-01 (MP)

You’ll need a two part adhesive mixer tip if you want the convenience of a mixed dispense. McMaster sells lot’s of options with the bayonet connection. If you want to step down to a fine needle application, you will want a Luer Lock hub mixer. Then any common dispensing needle with Luer Lock Connection can be used.

Static Mix MA Long, 62-9178-9150-9 (3m)

Static Mix MA Short, 62-9171-9153-8 (3m)

Static Mix MX 4:1/10:1, 62-9154-9136-9 (3m)

I cleaned up the hose brazes on to ensure good adhesion. I also took out high spots and made sure they were in good shape before sticking them on the forks. You may need to scuff the surface of the frame and/or fork to give the epoxy something to grip. Acetone should be used on all surfaces to ensure a good bond.