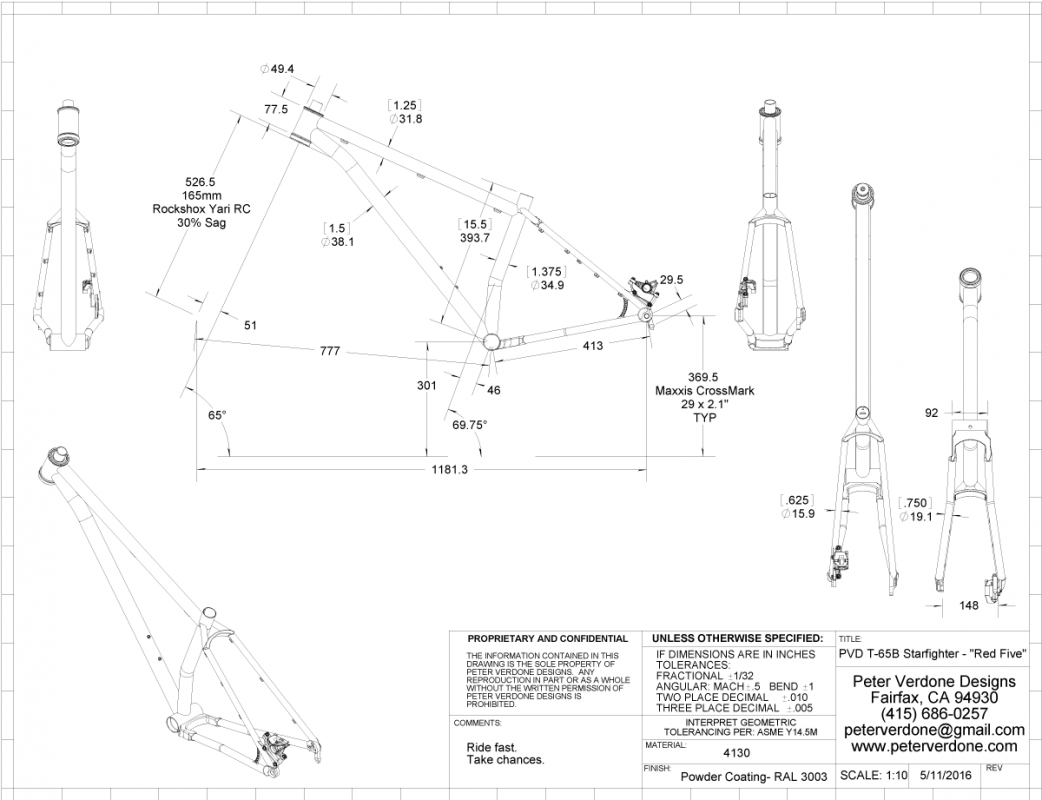

The Incom T-65B X-Wing Starfighter in the Red Squadron of the Rebel Alliance. The call sign of this fighter in the Battle of Yavin, Red Five, became the ships name. This bird flies circles around Imperial TIE fighters and blows up Death Stars. Boom!

I like to think about out running TIE Fighters and blowing up Death Stars when I ride. Like the Sheriff and rangers guarding Tam.

Rebel. Alliance.

It’s been a while since I built a proper trail hardtail. A long while. Framebuilding isn’t my thing. I kinda hate it. I don’t find it fun, or fulfilling, or even much of an achievement. What I want is a bicycle. Not just any bike, the right bike. That’s changed over the years as trends, my riding skills, and my own understanding have changed.

Why so long? My heart wasn’t in it at all. Some depression. Distracted by other issues in life. Dedicating myself to the project was the last thing on my mind. What was best was to get out riding so I did.

Also, I was learning more with store bought bikes. Big full suspension bikes. Small full suspension bikes. Squeezing all I could out of the hardtails that I had. I’ve fit and set up a bunch of folks on their bikes. Still, two previous frames got chopped up before coming off the jig. The moment had passed and they were antiques. Antiquated before being born. That’s where we are with mountain bikes. Changing so fast…

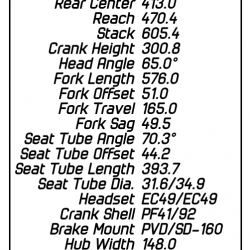

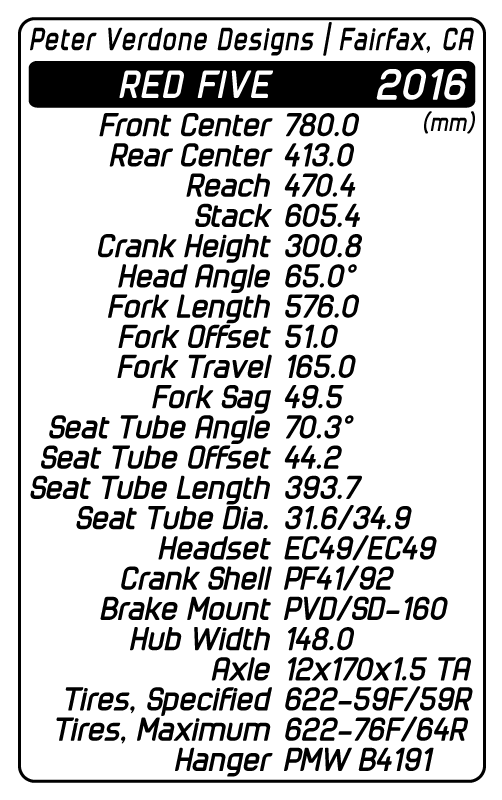

Anyway, I’ve been riding a lot of big bikes and learning a ton about fit and geometry. This bike is the culmination of that. This is a no-holds-barred destroyer of trail. A poaching rig that can outrun rangers and any non-expert on a full suspension bike. It’s put together for Marin singletrack. Lot’s of steep fire road climbing and technical singletrack descents. No gimmicks. No gingerbread. An honest to god mountain bike.

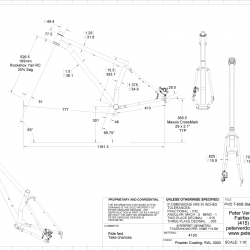

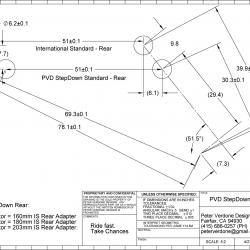

Modern mountain bikes are very short in the rear and very long in the front. Both pushing the reasonable limits of design. We want narrow stances and wide rims. We need to hammer up climbs and dive into rough. We want to go fast safely and slow exactingly. A bike as low as possible without problematic pedal strikes. We want light, cheap, strong, and bling. Getting to this isn’t easy. It’s hard. Especially with steel. Without the investment in costly yokes and bent seat tubes, I wasn’t going to get a result worth working on. I made that investment.

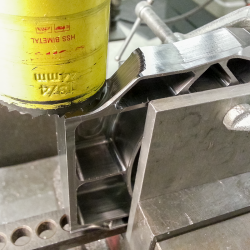

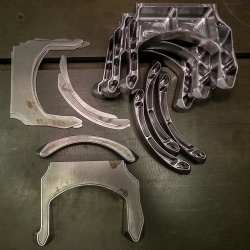

At the NAHBS show, I got to talking with Devin Bodony who makes the Lichen Bikes. The machined parts on his bikes are fabulous. He also has his own CNC Shop, Stirling Machine Works. I thought that Devin would be the perfect guy to make my yoke parts and I was right. I wasn’t looking for manicured detail, price is important for us hobby builders. I needed good parts at good prices delivered as promised. Devin delivered and I can’t wait to give him more work.

Other parts were water cut at my local shop, SMP. Keep an eye out for Keven and his insane SRL machines and shows.

I cut my own head tube, BB, and seat tube insert.

PF41 and 31.6mm seatposts are the best options going for modern mountain bikes. Dropper posts are only helped by using larger diameters and the PF41 bottom bracket shell provided the widest bearing spacing and works flawlessly.

OnePointFive! It’s back. The limitations of 44mm and 44/49mm head tubes become a real problem when configuring a bike for different courses. A 44mm head tube doesn’t allow the use of an AngleSet. The 44/49mm head tube only allows for a lower Angleset. A 49mm head tube allows for a top and bottom gimble in the AngleSet. This is important and is the key to a high performance mountain bike.

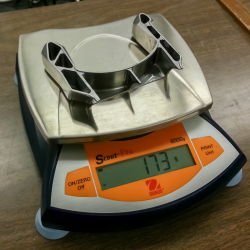

Weight: 28 lbs 10 oz.

One of the greatest things about going to machined parts in the rear end is that I had a single 5 degree bend in the chainstays and none in the seatstays. Easy peasy.

The bent seat tube is another story. 1 3/8″ x 0.035″ 4130 bent at 15 degrees around a 5.5″ CLR. Hammer of fucking Thor!!! Next gen will hopefully have a 30 degree bend.

Paint:

RAL Classic #3003. Ruby Red. RGB 134, 26, 34. CMYK 30, 100, 80, 20. Rad.

Fork:

RockShox Yari RC. My goal was to set the fork up at 170mm. While that could be done in theory, I would have ended up with poor bearing overlap at the very top of the stroke. I decided to back down to 165mm just to play it safe with the new fork. This is a stout fork along with the Torque Caps making it stiffer, it should handle some pretty hard duty with wagon wheels at this extension.

The damper in the fork will allow 190mm of travel. The 29er/27+ chassis is limited to 165mm. The travel is controlled by the spring side shaft. 235 = 140mm travel, 245mm = 150mm travel. 255 = 160mm travel, 260mm = 165mm travel.

Current configuration, 80 psi. 0 tokens. Red Line Blue fluid. Oil height was lowered @ full extention from 104mm to 115mm. Lockout needs coverage at 125mm so 10mm should make up for some slant and sag. Hopefully, I’ll have an easier time accessing the last 30mm of travel and maybe add a token or two. The fork feels pretty great in riding even with the cheap damper. I may try to lower the oil another 10mm.

Wheels:

The wheels are 110/15 and 148/12 spaced. 2.0/1.8/2.0 spokes and black alloy nipples three cross. The rims are WTB KOM i25 front and WTB Frequency i25 rear. We want 29er wheels to be as light as possible but the rear wheel of a modern hardtail needs to be Mack Truck tough. The rear wheel is going to be punished and broken quickly. It needs to be tough. The front will see far lighter duty.

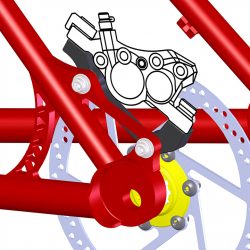

Brakes:

I’m a Shimano fanboy in crisis. For years they have been making the best brakes in cycling, period. Lately, though, many of their corporate and sales practices as well as little drivetrain development in the past 4 years, my foundation is cracking. I recently purchased some cheap SRAM Guide R brakes for a cool experiment. Having those, I figured I’d run them. They seem nice enough on the bench but I really really hate having to play with DOT fluid. I wish SRAM would move to mineral oil like their other hydraulic systems.

Tires:

Maxxis CrossMark EXO/TR 29×2.1″ tires are really nice for 29er duty in Marin. They are fairly light, very tough, and have great traction. I’ll see what effect the improved geometry has on my traction needs but I figure I’m at a good starting point.

Seatpost:

RockShox Reverb Stealth B1 31.6mm, 170mm stroke. The new B1 seatposts are excellent. Surely, the best posts going. 150mm isn’t that much stroke for my big enduro bike so we’ve been moving to 170mm strokes. Hardtail bikes follow.

Hub Engagement:

SRAM 1X11 systems really like high engagement hubs. The large diameter sprockets magnify the movement needed to engage a pawl. This is further magnified by the larger wheels. I’ve swapped out the DT ratchet to a 54t (HWTXXX00NSK54S) to have the best drivetrain performance possible.

Saddle:

I’ve been getting some saddle pain on rides lately. I’m a little out of shape and that may have something to do with it…or I’m just old. I’m playing with new stuff. I’ve been on the WTB Silverado 133x274mm for years. I like the 10mm extra nose in the design. I’m trying the WTB Volt Race 142x265mm. It’s been nice so far. I do miss the extra nose though.

Stem:

Originally the bike was configured with a 30mm stem and 20mm rise bars. In riding the bike, I’ve moved to a 45mm stem and flat bars. I’m waiting on a 50mm stem. That will completely dial in the fit and provide a good foundation to work from for the other frames. Riding is where assumptions and reality fight. Getting a fit from an EWS Pro style bike and conveying it to a trail hardtail is quite the translation. The prints here reflect the change.

This is the first of four 29er mountain bikes using these yokes. I’m excited to get the next few done. There are already several real improvements being implemented to this already sick bike. A new seat tube for smaller riders and more dropper plumbing clearance. Improved chainstay bends for SRAM Q150 cranks. An improvement on dropper line entry to the down tube, possibly through the head tube.

![t_65b_x_wing_fighter_by_woodylwg[1]](http://www.peterverdone.com/wp-content/uploads/2016/05/t_65b_x_wing_fighter_by_woodylwg1-1200x675.jpg)