Bicycle framebuilding is a particular simple craft. Connect a few bits of material together and strap some wheels to it. What makes good framebuilding difficult is everything that happens around the build.

One of the harder issues to get up to speed on when making bicycle frames on a small scale is the lack of proper tools; are they available and affordable. Large asain manufacturers have decades of large and expensive tooling built up so that they can churn out high quality bikes without much challenge. It’s not like that for the craft builder. In recent years, some good attention has gone to improving the frame fixturing component of small production but we’ve been suffering dearly at the fringe for a long time.

By definition, small framebuilders are at the bottom of the bicycle production food chain. Many are working from the back of bicycle shops, basements, or the home garage. We rely on large tool brands to foresee the need for tools that we and shops use. This only makes sense.

This leaves us to shop from companies like Park Tool of USA, VAR Tools of France, Cyclus Tools of Germany, Silva of Italy, and Hozon of Japan. Truly, this is the market that these companies profess to supply. They make the special tools for producing the proper cutting of the frame to size for the headset, seat tube, and bottom bracket.

It’s important to have tooling that is available locally as service may be required from time to time. For folks in the United States, these are the tools that will generally be needed for building modern bike frames:

- PF41 Crank Shell Reamer (40.98mm) (Park # 744) $149.08

- EC49 Head Tube Reamer (49.57mm) (Park #758.2) $442.18

- IS41 Head Tube Reamer (41.15mm@ 45°) (Park #756S.2) $227.14

- IS 52 Head Tube Reamer (52.1mm @ 45°)(Park # 738) $157.66

- ZS44 Head Tube Reamer (43.95mm) (Park #788) $152.98

- ZS56 Head Tube Reamer (55.95mm) (Park #789) $206.12

- 31.6mm Seat Tube Reamer (Spiral Flute, Hand) (Unavailable in USA)

It seems that the folks that work to design these tools have no understanding or interest in what goes on in frame design or production. So many past tools have just been insane. This has also cost people lots of money and held product design back.

The Park #756S, 41.15mm Reamer & Facer Set and the Park # 758.2, 49.57mm Reamer / Facer were (and still are) some of the worst designed tools I’ve used in my life. They were designed to be exceptionally expensive and difficult to sharpen. At $442.18, the cost of the #756S killed any chance of the well suited EC49 cup from being used in the small framebuilding world. This is where EC44 lowers came from. The set of #756S nearly did the same for the IS41 headset.

To be clear, most people didn’t choose to use these interfaces because they were bad. They didn’t use them because doing so was financially punitive. That’s a big difference, especially when there was no good reason for tools this bad to be put into production.

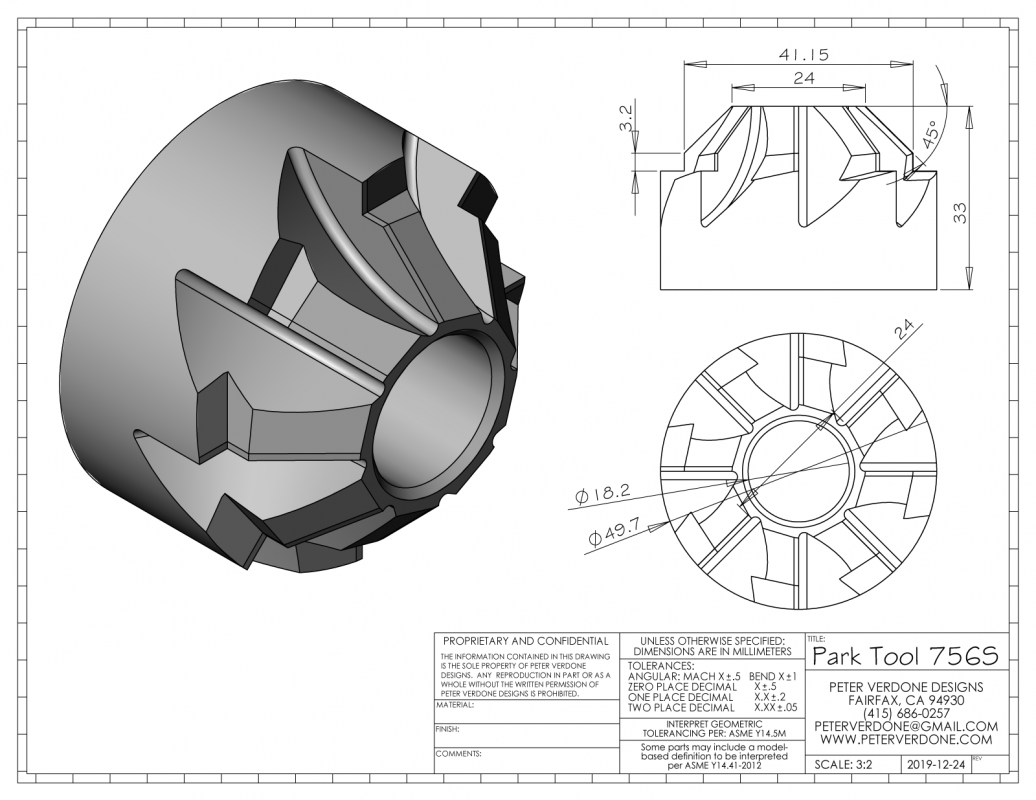

Here’s a print of the 756S. Who thinks this crap up?

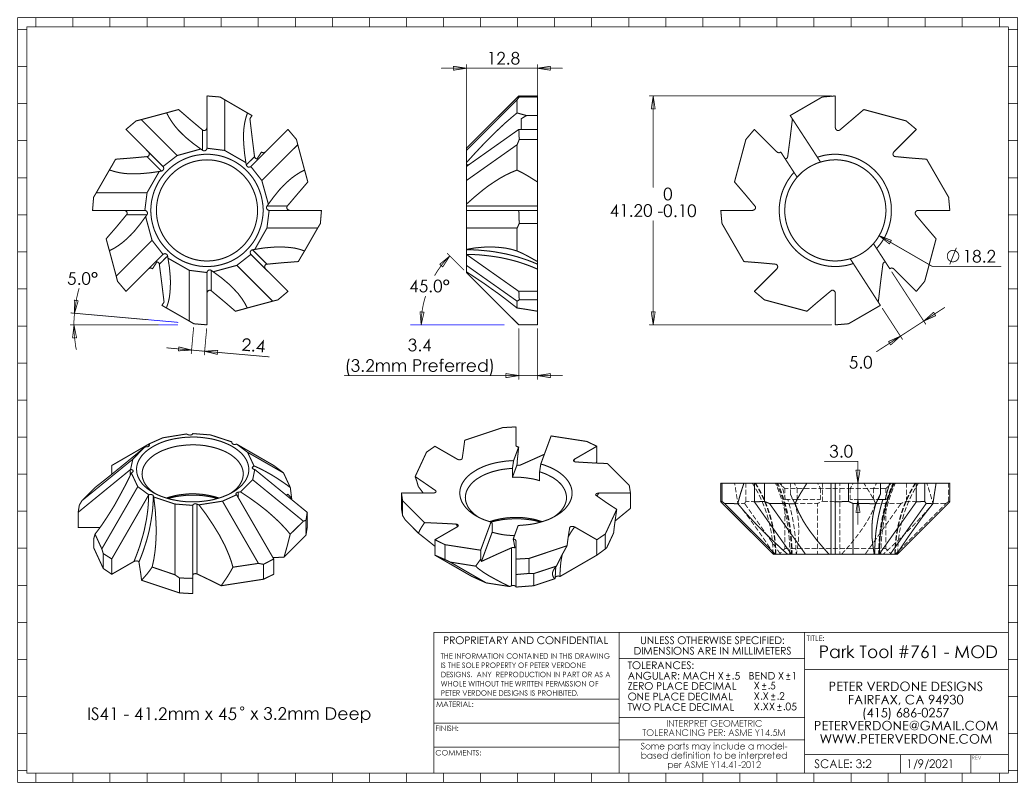

Just recently, I had a #761 (IS42, new style) reamer cut down to 41mm as Park hadn’t released a new style reamer for that to the market. So I had to buy the wrong size tool, and pay to cut it down, because almost nobody uses IS42. Then, (this week?) it seems that the 756S.2 (new IS41)reamer was release. What a total waste! Here is the print that I gave the grinder:

The hardest part of all this is at the seat tube. For seat tube reaming on high end bikes, the only option for the builder (in USA) was purchasing a cheap 1-1/4″ spiral hand reamer and having it cut down to 31.6mm. Amazing but true, this is what needs doing. There exists no better option than this. We don’t use adjustable reamers on frames as they really are for ’emergency’ or roughing. For final cuts, they can produce tapered bores.

Elsewhere in the world, a Cyclus #720061 with a #720101 (31.6mm) attachment can be had for seat tube reaming although not the greatest tool, affordable when close to Germany. It’s not a great tool for production, but it’s possible for finish work, I guess. Silva Supposedly has a Seat-Tube Reamer Kit, locally, Torch & File (the USA distributer) doesn’t have it in stock.

Dispite PF41/86-92 being on of the more popular crank shell interfaces in the last decade, it was only a couple of years ago that I was able to buy a cutter from Park Tool for this cut. Until then, I was forced to use a gigantic 41mm hand reamer (custom ground) in a lathe (rotated by hand). This makes no sense. Again, another great interface that struggled in the cottage industry due to lack of tooling available to the masses.

A few years ago, I even needed to make a proper conical pilot for certain operations. Why hasn’t this been added to the kits, over a decade after the need began? This is such a simple par of the system but continues to be ignored.

Tool companies really need to take a serious look at the reamers that they sell and what they support. Decisions made by people without real understanding of the full picture has a huge effect on the progression and possibilities in the most creative segments of the market.