One of the most important characteristics of a skate truck, but almost totally ignored, is the roll center. I was one of the first people to discuss this back in 2000 (20 years ago!) and I’ve seen a few people replicate my explanation but not many. As I’m wrapping up the design of the new trucks, I saw an opportunity to show this in the context of a complete skateboard model and discuss the math.

What is the roll center? Simply, the roll center of a skate truck is the point that the board and hanger actually pivot over each other. This can effectively be seen as a static location but like the wheelbase, this point will lower very tiny amounts as the board is tilted.

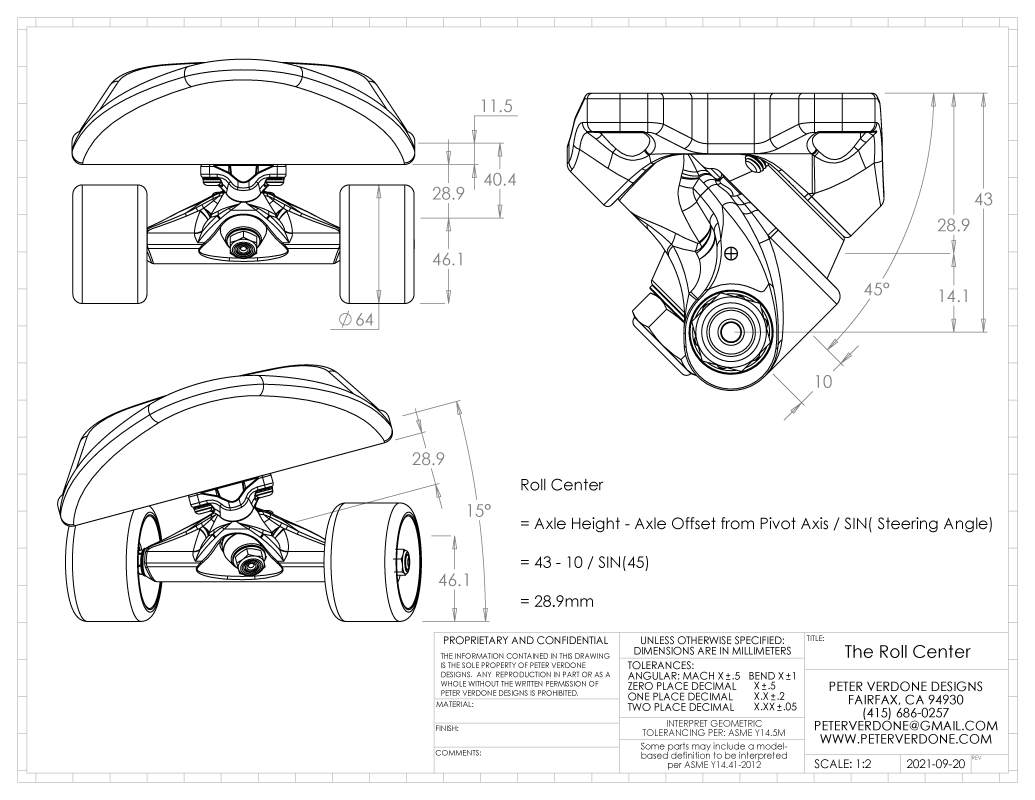

Geometrically, the location of the roll center is vertically from the axle and intersecting the steering axis.

This is important to the rider as it will effect the feel of the skateboard. A roll center that is very close to the deck top will result in a tippy feel. A roll center that is far from the top of the deck will result a swooping feel. In terms of grip, the closer the roll center is from the ground, the better as the inside and outside wheels will be loaded more evenly. Depending on what the rider is looking for from the skateboard, this would be important to know.

In the example below, the roll center is 28.9mm from the mounting surface of the truck and 40.4mm from the top of the deck. Sadly, we don’t get to make a lot of choices about some parameters when others are more important, the overall height of the truck, steering angle, and the ability to block the tail. Packaging is always the most difficult problem in engineering. It is what it is at this point in the process.

Roll Center = Axle Height – Axle Offset from Pivot Axis / SIN( Steering Angle) = 43 – 10 / SIN(45) = 28.9mm