I tell people all the time that I’m not a very good welder. I know good welders. I am not one.

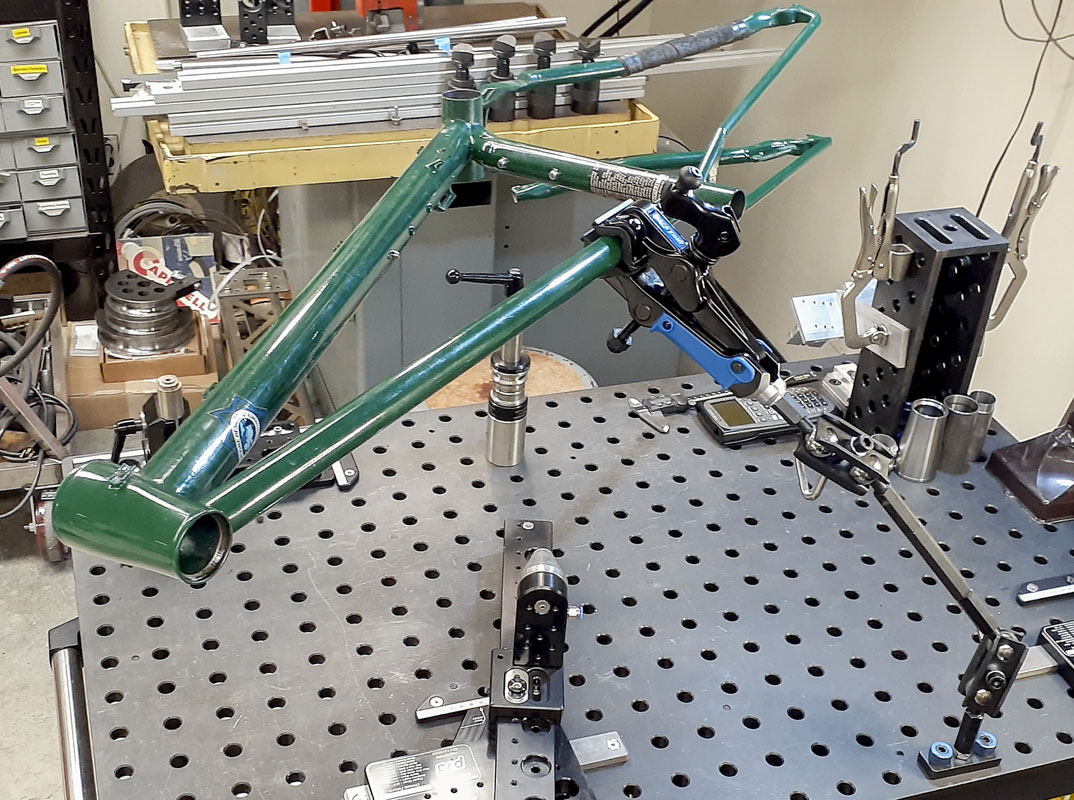

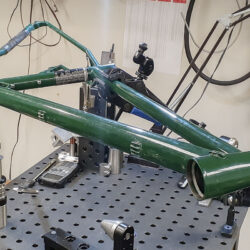

Still, I need to get metal connected and I can use all the help that I can get. When welding a bicycle frame, it needs to be held in a lot of interesting positions to get into the tighter spots.

In a recent post, I share a visit to Brad Bingham’s shop. There, he has a great pillar for holding frames for welding. This is a freestanding unit. I show the base here as it’s pretty slick.

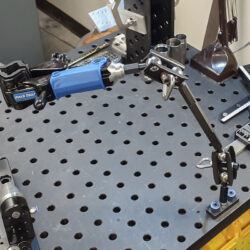

As I’m doing all my welding work on a BuildPro RhinoCart table, I have nice options for quick mounting to the surface. I can use a magnet or clamp directly to the table. I currently think that directly mounting to the table is the way to go as I can be totally secure there and focus on the arm as the weakest link.

I got a cheap arm from the BuildPro catalog, HAS40, for $36.68. It’s ok. I wouldn’t say that it’s the best thing but it’s cheap and will get me up and running before I work to find a better solution.

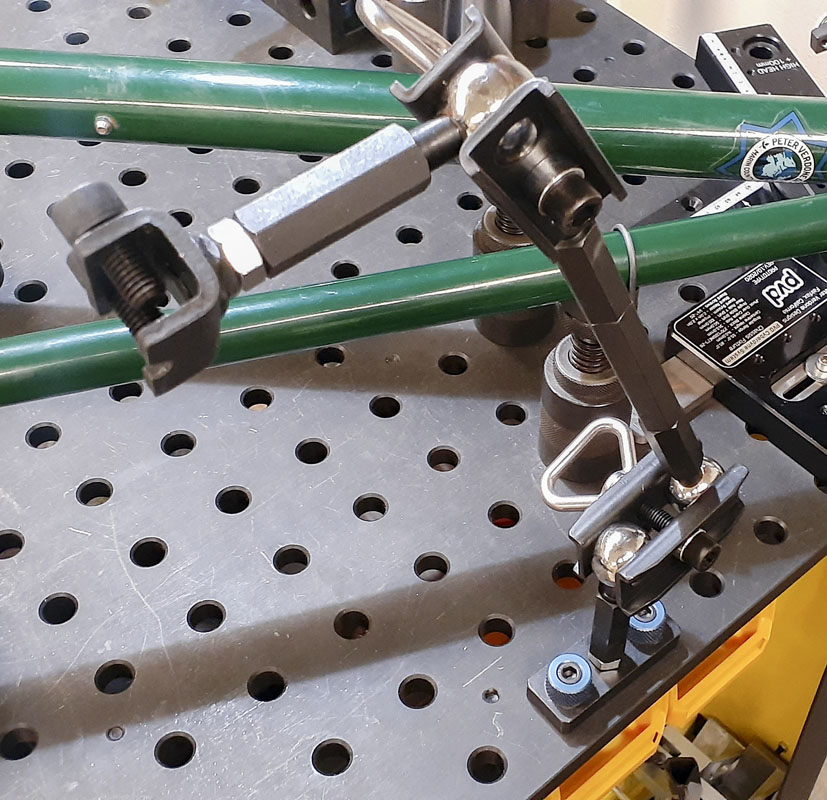

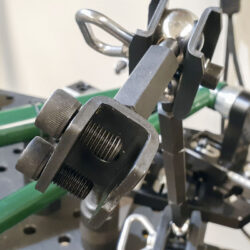

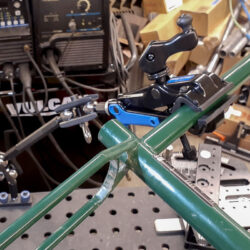

A user on Amazon suggested a great and cheap upgrade for this. Reverse the clamping bolts and replace the M10 nuts with eye nuts. This is what the tool should have come with originally! It makes tightening the clamps very quick and easy at high torques.

- 304 Stainless Steel Eye Nut M10 Triangle Ring Shape Lifting Eye Nut Set Threaded Nut Fastener 6PCS, $14.69 on Amazon

I have a few options for improving the flexible arm. These are much more expensive solutions and something that I’ll hold off on trying until I figure more out with the cheap stuff. I like the Swivellink stuff but it can be expensive with quick releases.

- Noga Power Arm, 510mm (PA1500 or similar)

- Swivellink mount assembly.

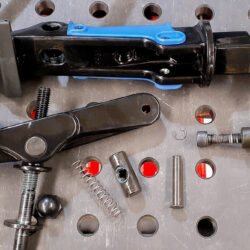

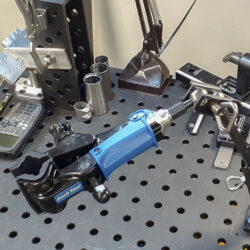

I have a clamp for the end of the arm, the Park Tool 100-25D Micro Adjust Clamp. I really tried to find something better for grabbing hold of all different diameter tubes and such. This is a pretty good option…with a few modifications.

I trimmed the back end of the tool to make it less cumbersome and cleaner to mount to an articulating arm.

As configured, the arm is just capable of holding a frame in space over a table. It isn’t super solid like this. It’s fine and solid enough with some part of the frame resting on the table. I’m considering spending more for an improved arm. I just need to look around for options and what that should be.

Stay tuned and you may see the final draft of this.