“I would have written a shorter letter, but I did not have the time.” -Blaise Pascal

COVID-19 is a bad thing but many of us keep trying to find and see the good things.

One thing that I have enjoyed about the COVIDs is the time I can spend really savoring the design process. As I wait to go back to work, I have time. Lots of time. I keep filling it, for now, with good projects that I can do from home. I can spend hours in a virtual world, day after day, but resulting in tangible, real world design that will be made and used.

I know that there are many people losing their lives, their family, and homes in all this. I get that. Humans, though, will find a way to escape from disaster and horror to make art, sing, dance and laugh. That is what we need to do as people. If you can’t find something to make you laugh in the worst of times, you probably don’t have your priorities straight.

I like to look at problems in my world and solve them, as silly as they are in the grand scheme. This is my folly. It kills the time in a nice way and sometimes it’s even useful to others (or even my wife).

Since getting back on bike after all my problems this winter, I’ve been very focused on the Spitfire. Part of that is sorting the flat mount calipers that I’ve been using. Finally, as I’ve been getting the klunker up to real speeds in really rough places, I’ve been running out of brake. I need more power and more control.

It’s time for some real calipers and levers that are fit for the way I’m using my brakes. As there are no real gravity oriented options in flat mount on the market yet, I’m going to have to use a SRAM Guide RSC system that is only available in post mount.

This means that I now need to make some adapters for my bike. This is the problem of being a leader in technical developments. I can’t just go to the store and buy adapters for much of what I do.

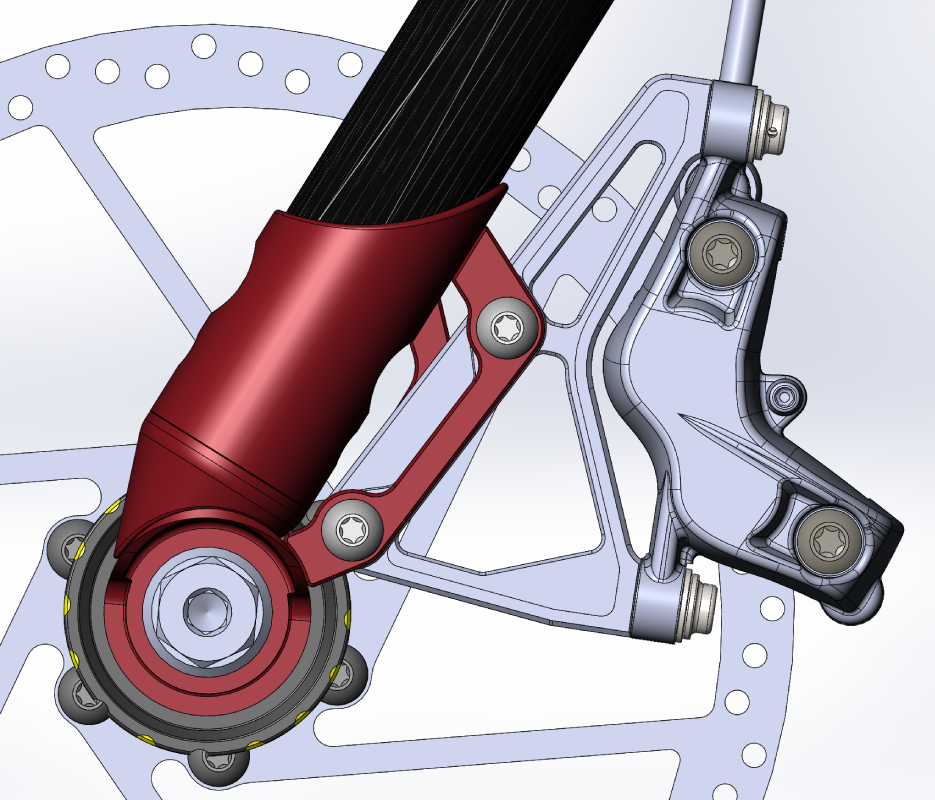

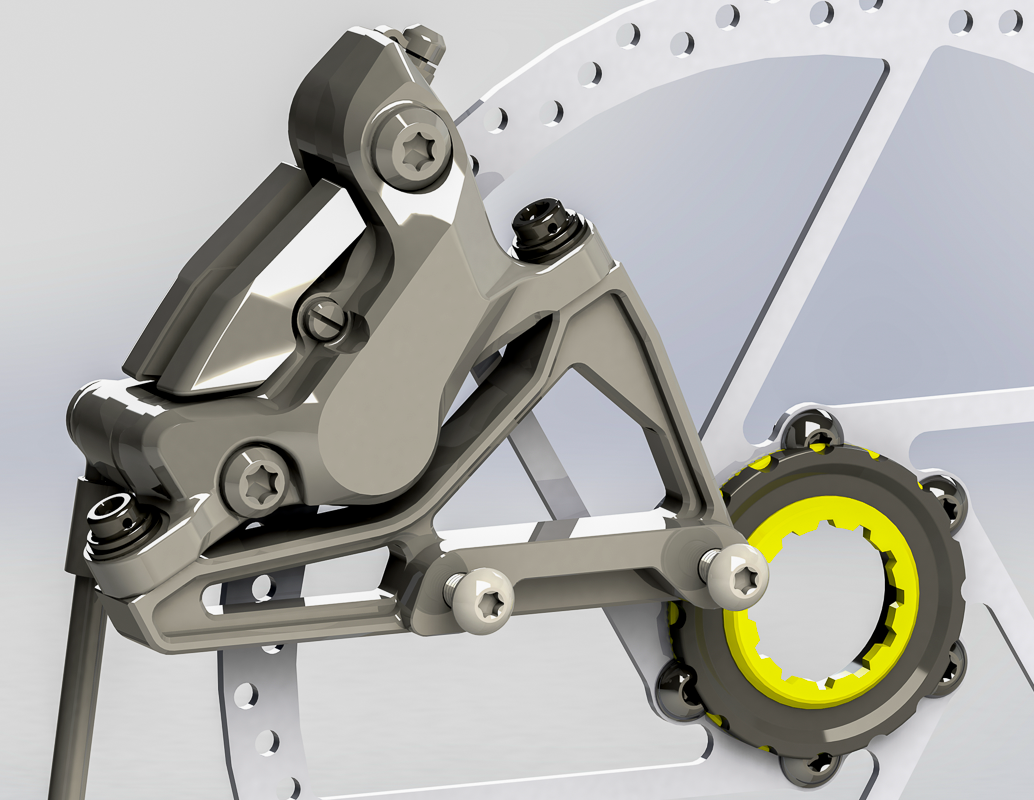

I use a proprietary PVD-Sidewinder brake mount on my fork and a PVD-FM32/160 mount in the rear. I’ve been using 180mm rotors with the Hope X2 master and RX4 slave system. Adapting to a PM60-180 from both of these mounts is going to mean metal chips.

This all stems from a solution I used on a Firefly dropout a long time ago. That became the (now antiquated) PVD/Stepdown, Later, a whole restructuring of how we look at brake mounting. After so many years and iterations, I’ve got a real handle on this topic.

Sidewinder is a pretty cool solution that I came up with for fabricating a composite fork as I did for Spitfire. It’s very low and out of the way. It look nice. It’s simple. It also works with flat mount and post mount calipers of all sizes. It’s worth a look for those who work in this realm.

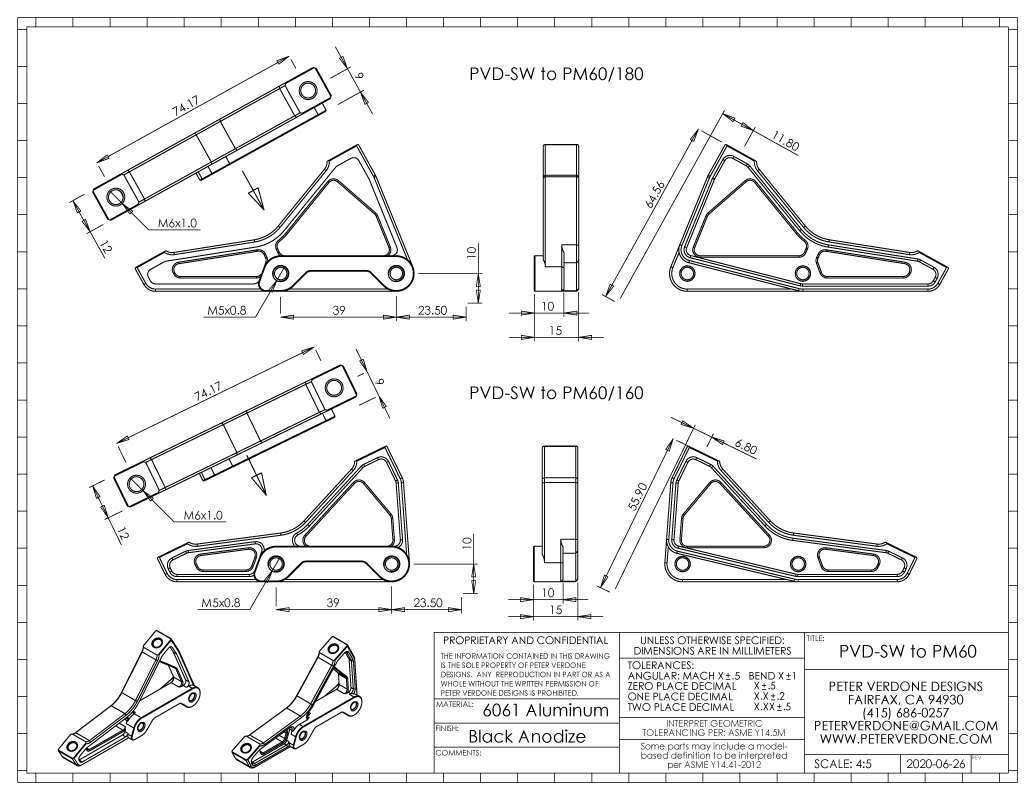

So, I sat down this morning to draw up a pair of adapters for just the fork. They are for use with 160mm and 180mm rotors and post mount 60-degree system from PVD-SW/140. A basic and well defined problem.

Certainly, this part could not have been designed in one day without a full architecture of other parts to model in an assembly. I didn’t have to do this part today. I have many many years of modeled parts in my inventory and 90% bike assemblies to work with. This makes checking fitment and appearance much easier when I want to throw down quickly. I can just jump into existing work and start slashing and burning. This also helps to remind me what I’m forgetting when I see interferences and close calls.

I played a lot of tricks with the design of these adapters. You see it as you keep looking. I’m fooling the part into being stronger and lighter than it wants to be. Design is just coercion. I’m getting a chunk of metal to do what I want it to do and look good to. Sometimes, that takes more convincing than you’d think.

These adapters aren’t even done yet. I still need to check them against other calipers besides the SRAM Guide caliper that I have shown. I don’t like surprises and fitting most common post mount calipers is important. If it’s important, you check. That will be done tomorrow or the next day. Sometime when I get back to this. There’s no real rush. This is COVID time.

This print isn’t even very usable yet from a production perspective. It hasn’t been toleranced. That’s critical to having it produced. It’s going to take some time to check everything and make sure I get that right.

So this is it, two similar versions of the same simple part. No fantastic machine. No wiz. No bang. Just a part that’s almost done. 8 hours of intense design from an expert and this is what you see.

I say this because many people, especially the young, have false ideas of how long design takes. How many iterations a design sees before it gets made. They just don’t understand how many hours of drawing, checking, revising, testing, checking, starting over, and such really happen. I blame Hollywood and YouTube. A 5 minute montage scene produces just the right thing that works on the first try. Pure fantasy but all that the novice really knows.

The final draft of the part, several days of work later. The differences are very subtle but are the difference between good and shoddy design work. Doing deep repairs to my brake system modeling base and checking against several calipers was most of this.