This is interesting. Running a 220V3P Bridgeport mill from a 120V1P power source. Are you interested?!

Industrial spaces in the United States will have 480V 3-phase power running to them from the utility company. This might be stepped down (delta transformer) to 240V or 208V in 3-phases. In our homes (US) we will generally have 240V 1-phase supplied by the utility with that split to 120V 1-phase power coming from wall sockets. 240V 1-phase often remains available in washrooms and garages. As we live in North America, all of these will be alternating current (AC) cycling at 60hz.

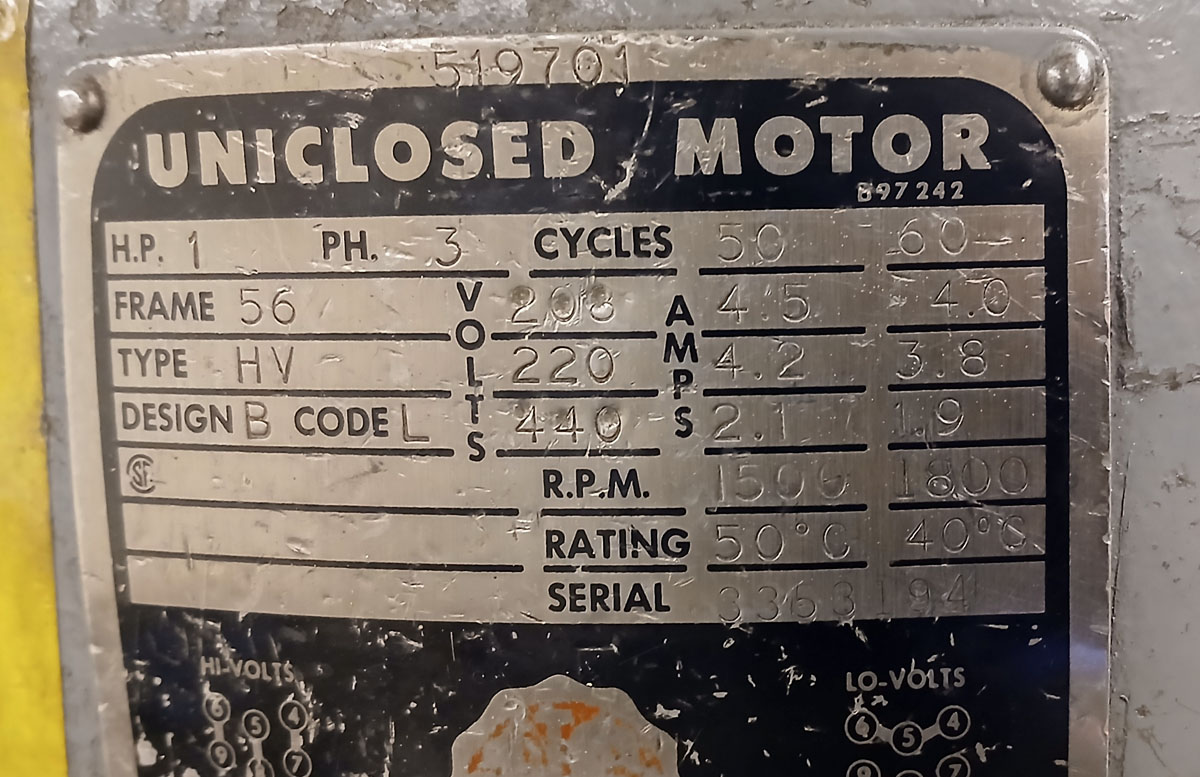

Most Bridgeport milling machines motors that you’ll encounter in the wild are running from industrial 3-phase power. 220V/240V on a 20 amp circuit although permutations exist. I prefer a flexible line that terminates with NEMA L15-20P plug and L15-20R receptacles. These will support up to 250V and 20A.

Here’s the problem, if we want to use a milling machine in a residential homesite, we typically won’t have sufficient power available without considerable work running a special service. We will most often connect to the 240V supply and run a phase converter of some type to generate the 3-phases. I realized that I hadn’t really seen an example of running a full size mill from 120V supply. I did that today.

I have this little Teco Westinghouse L510 Micro AC Drive (VFD) (L510-101-H1-U) in the shop. I’ll use that!

https://www.tecowestinghouse.com/wp-content/uploads/2018/08/L510_instruction_manual.pdf

These seem to have gotten a bit more expensive in recent years (now $200-350). Still, off brand imports show up on Amazon for around $100.

If this is a long term install, it would make sense to start thinking about running a proper 240V 1-phase line to the machine and a VFD that is designed for that rather than 120V. If need be, a transformer can be used at the machine to step the voltage from 120V to 220V. Elegant solutions in any particular case will require some thought.

It seems to work OK without much time spent tuning. As I say in the video, I had to bypass the contactor and give it a real slow start but I was cutting metal. I was looking at another video where they used a 3 second acceleration time compared to my 10 second time. That may be a good place to begin tuning. I’d love to learn what the cool kids know for getting these setup just right. I’m not really focusing on this right now as I’m all about the hydraulics these days.

You can see in the video that the mill is cutting just fine. I could have done more but I was in a rush.