I wanted to improve on what I was doing with head tubes. It was May 2023 when I had moved to a modular system for IS41/IS52 head tubes. This allowed me to easily fabricate a nice head tube of any length.

The issue is that all of my bikes (outside of road) use the same size tube, 85mm. I realized that for the cost of two press fit head tube ends, I could just have a whole 85mm head tube machined and reduce the OD some.

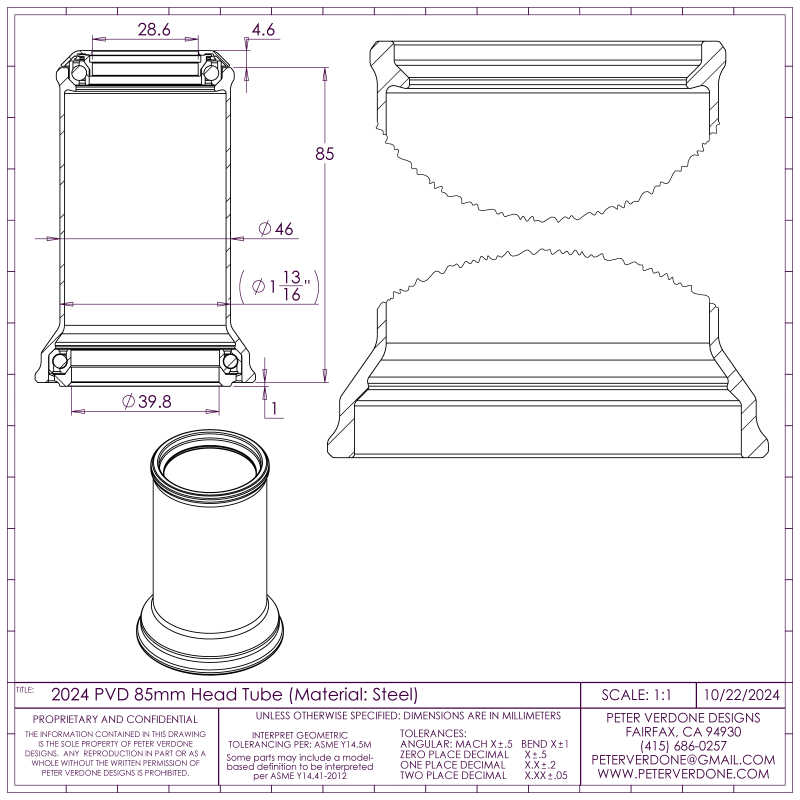

This new tube allowed me to reduce the OD of the main tube section from 50.8 to 46mm, a 4.8mm reduction. That’s not trivial and lightens the look of the front of the bike. While I could go even more narrow, that would move the bottom flair higher up the tube. This is a balancing act that has to be just right.

This new tube allowed me to reduce the OD of the main tube section from 50.8 to 46mm, a 4.8mm reduction. That’s not trivial and lightens the look of the front of the bike. While I could go even more narrow, that would move the bottom flair higher up the tube. This is a balancing act that has to be just right.

The flair on the bottom of the tube reaches out to match the crown of a typical RockShox fork. If the tube is being used on an all-road bike, that can be trimmed down quickly on a lathe to match the crown on that bike. I screwed this up on the last round of lower head tube inserts. Now I got it right.

The expanded ring at the top adds to the texture. It makes the part come up at you. I need to think more about how to describe it. Optimal fit has a Cane Creek Hellbender 70 Slam, IS41/28.6 Top Assembly (BAA2164K) in place.

The machining of the part is magical. They arrived to me feeling so soft in the hand with a luster like jewelry. I’m going to feel bad as I get medieval on it in production.