I chose ‘Gulfstream G650’ as the namesake for this bike as that plane is a sleek and fast corporate/wealth jet that is designed for fabulous people to move about the world quickly and without any hassle. It’s the benchmark private jet for the most elite of us equals. This bike is a road+ design that is set apart from all the rest. Class, style, speed.

This past May, I built Windy’s new road+ bike, the Electra. I was shocked by how excited that I had become with that build. Like a palate cleanser, working with the road+ bike has given me a refresh of thinking in contrast to all of the dirt bikes that I’ve done in the recent past. It was encouraging and felt new. I figured that doing another road+ bike for myself would satisfy a need (I currently lack a nice road bike) and give me a second chance at improving on a few of the details and decisions that I made in the design and production of Windy’s bike.

It’s a challenge to jump from designing one type of bike to another. Bike types are all very different from each other when we get into the fine details. Since I’m not an enthusiastic roadie, it’s even harder to move into that space in an effective way. Settling in with several iterations of road bikes helps with this; fine tuning the current design as well as what’s to come. Everything is fresh in my mind for what ‘could ‘ have been for the Electra. Taking intricate notes in hopes to some day implement arrangements. That day came soon.

Iteration is crucial in the bike creation space. I know that it is in many other arts as well. The process strengthens the ability to think and build critically and make future informed decisions. We never get it right on the first try. We still aren’t close by the fifth try. Changing and testing fine details at the scale that I work at takes a lot of time and money. I build two, maybe three, frames a year. That means that I need to keep up with all of the extrinsic changes (like UDH and crank shell systems) and find intrinsic improvements (moving the hose routing around five more degrees). A substantial amount of that work happens in the computer and in the head, rather than when in the shop pushing metal.

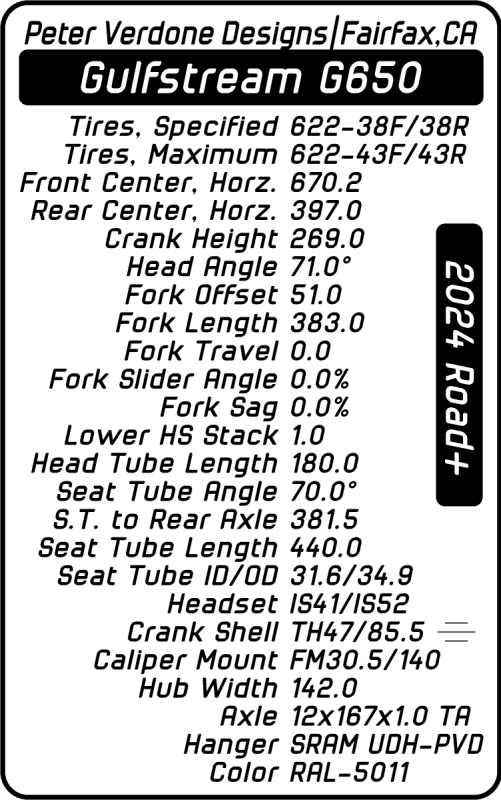

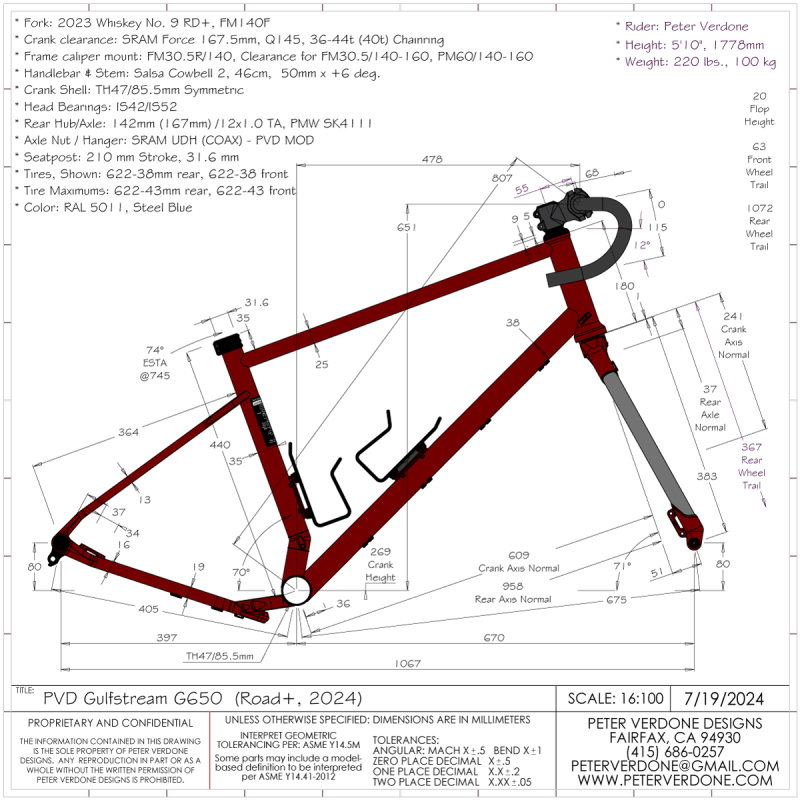

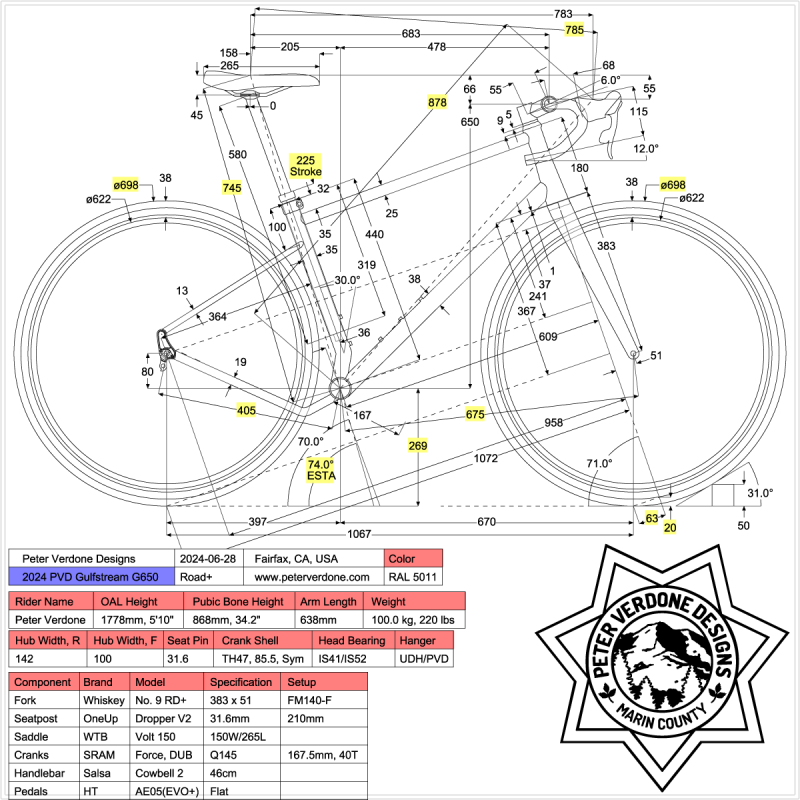

Those familiar with my work might notice a few changes in the frame definition that I’m showing for this bike. The front and rear centers are now being described horizontally. In my head, I’d been bouncing back and forth between the radial measure and the horizontal measure for the past few years. The problem of choice here is not simple. The radial measures are quite easy to discover simply by measuring the axles to the crank on the bike. The horizontal measure is not as simple. But it is the true description that describes the contact patch distance from the crank normal to earth. This is not a pedantic point. When I change geometries or tires between different designs, it’s the horizontal description that has the most meaning. For example, if I think about a change to a 584mm BSD wheel in the back of this bike, the radial centers will not be the same for similar behavior. The axle height will have changed 19mm which would necessitate a 3.3mm increase in radial chainstay to produce similar behavior. These are small but not insignificant values. I describe this further in another post.

The hardest part of this frame design was developing a workable modern geometry that fit me well and is aligned with the cutting edge of what I’m trying to do in the road+ space. I didn’t have a test bike with drop bars to ride in anger and I was getting very old information from my files. I’m trying to keep enough space in this design for fine tuning. Just a few millimeters too far and the bike goes from profound to garbage. I hope that I pulled that off. The 55mm stem is a reminder of that. I hope to be using a 45-50mm stem. I might end up with a 60mm stem. Ambiguity is hard to point to so I drew that in.

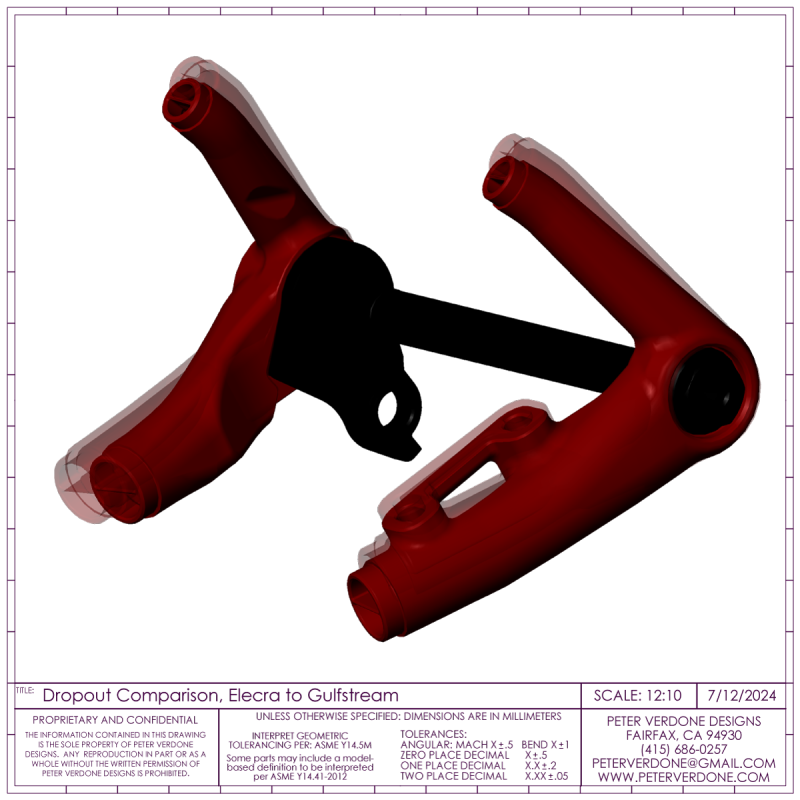

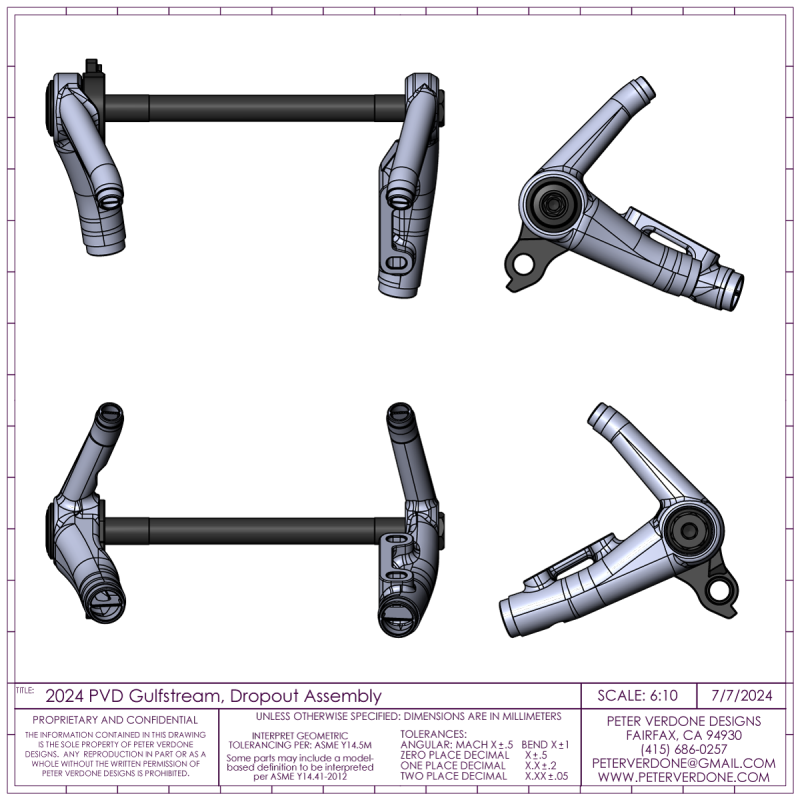

I wanted to focus more on improvements to the dropout design. That’s been where the action has been on my recent bikes. Heel clearance is still the primary focus but dropping the stay at the axle is a goal as well. Gaining just 1.5-2mm more clearance took another major redesign of the files. A few days in the CAD hole produced a bit more space. Moving metal to more advantageous locations makes a difference elsewhere. I believe that they are structurally stronger now also. The brake mount is FM30.5/140, so there’s some choking up toward the axle. They also look good.

Here’s a drawing that compares the dropouts as used in the Electra to those of the Gulfstream, both fairly similar in that this part of the bike. Subtle changes like we see here come from significant work and investment of time. What did I get here? Could it be better? Just a couple millimeters here and there but that’s exactly what separates very high end design from not.

The wildcat UDH spec that I use has been developed farther. I’ve been removing the fin from the insert for a while. Now, I’m lowering the chainstay into a space off limits in the official specification. It seems like I can trespass without cost. Once the bike is on the road, I’ll take another look at how well this works with the Eagle, Transmission, and GRX derailleur to see if there is more space to use here.

The chainstay yoke has clearance for a road double and 45mm chainline single chainring with Q145 crank. Obviously, this configuration would force the use of a smaller than maximum tire but this option may really help in a future case. I’d also have to produce a special mount for the derailleur to do this but that’s trivial.

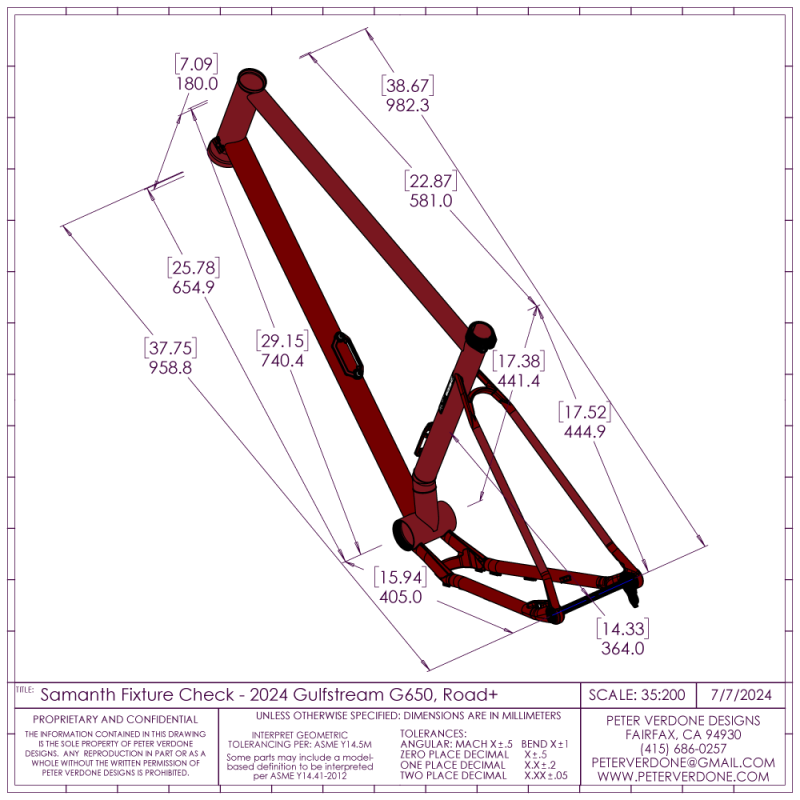

Here is the SolidWorks print of the model that I generally work from in fabrication.

The Setup print from BikeCad. I need to figure out a better way to show drop bar setup measures that have the most meaning. Better drop bar specifications could give proper reference points.

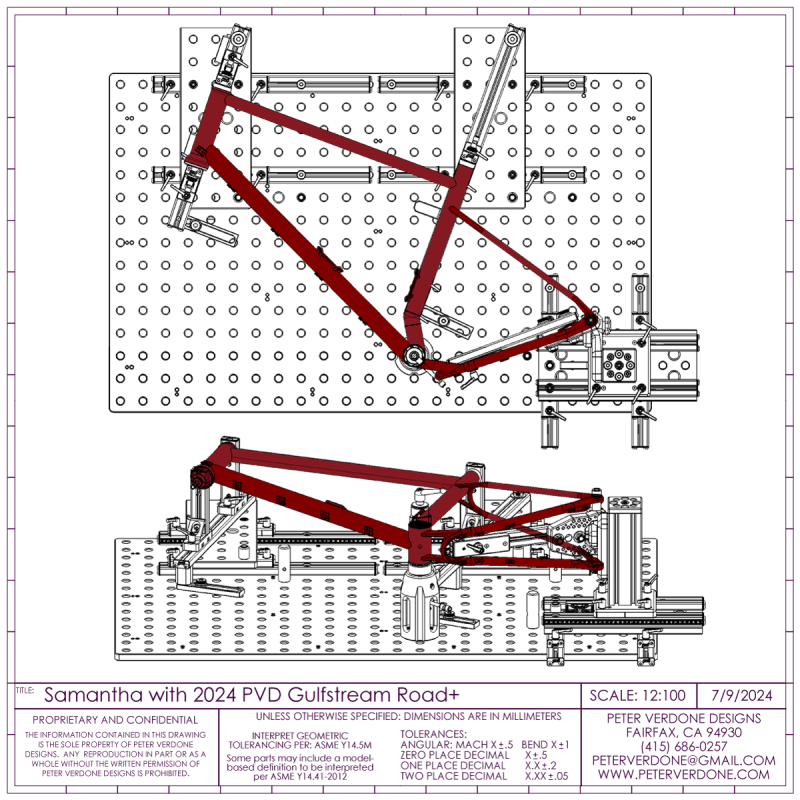

Setting the Samantha fixture was a delight. The calculator keeps getting better. I love it. Everything fit up as it should. New info in the calculator refers to frames with suspension forks so there’s only placeholder there for this bike.

Confirmation measurements were spot on in the fixture. It’s been interesting developing these measures and they prove to be very valuable. This is something that any builder could use on any frame fixture. More, I could develop another spreadsheet that worked in reverse, where a few measures of a bike in place could produce proper (and accurate) geometry values. Another project on the list.

The Gulfstream set up on the Samantha Frame Fixture. (It did not get painted red).

I chose RAL 5011, Steel Blue w/ Axalta Crystal Clear PFC400S9 clear coat. I’ve been doing a lot of lighter colored bikes lately and wanted to explore some darkness. I still want color though. This is one of those shades that will look black in the shadows but blue in the sun.

The initial build for this frame will include my old 46cm Salsa Cowbell 2 (now Cowbell Deluxe) handlebars along with a cheap Whisky/Salsa stem. I’m hoping to move to the new Whiskey Spano drop handlebar as they have a much shallower 100mm drop once I get to fine fitting and shaking down the bike. The 115mm drop of the Salsa bars shouldn’t be a real problem given the relaxed fit of the frame but I think the shallow drop and carbon bars will be rewarding for me.

The need for a real dropper lever and hydraulic brakes forces a single choice for left brifter, the Shimano ST-RX820-LA. We were forced to this on the Electra. Since I’m more informed now, I decided to also use the GRX 820 12spd shifting to match the set. The right brifter is ST-RX820-R. Because I’m starting with a 10-44 cassette, I chose the RD-RX822-GS (medium) cage to tidy things up. I would have preferred have a SRAM x-horizon rear derailleur in place but SRAM has no option for cable-actuated droppers with drop bars.

I chose to draw the bike with a 210mm dropper post. An off-road bike would take a 240mm dropper but a road bike gets less. Shorter droppers are much lighter and should be fine in this use case. Still, I kinda wanted the 240mm option after the die has been cast. The bend in the seat tube was moved higher than I do for mountain bikes to improve looks. I may see if I can get a 220-230mm setup in place. Cutting some 15mm pins will give me a 225mm drop in a 240mm but that depends on the bottom routing. I guess that I should have kept the 35 degree bend instead of mellowing out with the 30 degree. It’s a bad time to change my mind. I ended up just using the 210mm.

Brake rotors are 160mm front and rear. I’m moving to 2.0mm thick SRAM HS2 rotors for my recent bikes. I’m interested in braking quality and I’m heavy, so there.

I’m setting this up with Race Face ARC i25 front and Race Face AR i25 rear rims. Tires are WTB Exposure 622-36 x 700 Light/Fast 120tpi that measure 40mm wide on the i25 rims. This seems like a punky little setup without getting too absurd. They look nice. The frame and fork will still have ample clearance for 43mm tires with mud room for bigger adventures. As I’m mostly going to be riding around town with this, the wheels will be set up with tubes.

I’m going to try shorter cranks. It’s the trend. 167.5mm for road. I’m going to see how long I’m going to be able to handle it. Years ago I did some long term testing on crank length and found that the 172.5mm was what I preferred. Still, that was years ago. Everything changes. Maybe I’ll like the shorter cranks now.

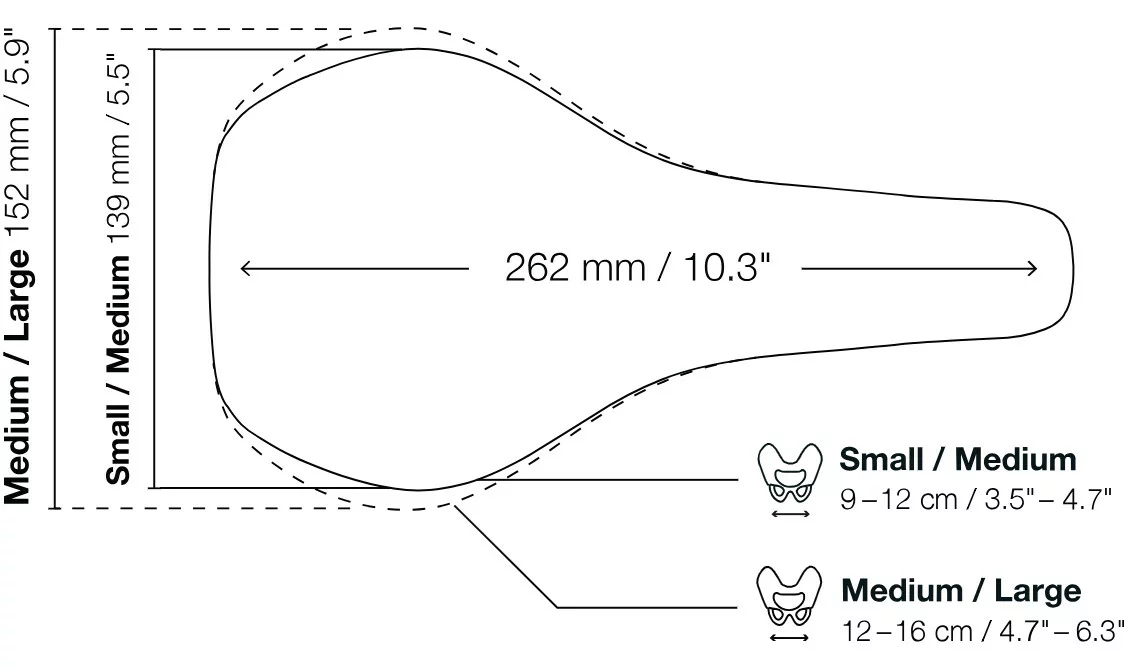

A new saddle for me, the Ergon SR Allroad Saddle (M/L). Not sure about it but trying something new.

The bike is being set up with flat pedals. The horror! My switch to flat pedals on MTB a few years ago has been fun. I like how I approach most things now. Playfully, without so much care about absolute speed. I want that on the road also. Like the all-road bike, this will use the HT Components AE05(EVO+) pedal. These are nice and narrow flat pedals, lending themselves for this use. I wish they spun easier but everything is not what we get.

I played a little it with the pedal pins. A little shallower than MTB pins. Just thinking about what might work best for road. Fresh territory.

It’s odd that it’s so hard to find the Fizik 2mm Tempo Microtex Classic Bar Tape these days. I did find some but it was shipped by slow boat. I like how rugged this tape is. I can crash and still have something workable. Generally I use thin tape and pad specific areas of the bar to keep the grip diameter down with the same cushion as thick tape. I would prefer this 2mm microtex tape in a soft touch but that seems out of fashion these days.

The initial build seemed to feel right with a 50mm stem. Shake down ride is tomorrow, I might bring a 40mm with me in case. I’ll update the prints when I’m done shaking down.

2024-07-26 – Shakedown 1, Bofax to Ridgecrest and back.

This was a small ride but has a taste of everything and at extremes. Serious climbs and descents with gnarly corners.

I was prepared to make changes needed by bringing a 40mm and 60mm stem along with me. The fit was pretty close to perfect with t he 50mm with a comfortable feel. The bike climbs just fine but the comfort position is battling the aggressive climbing needs, I’d like to get up over the front better when out of the saddle. It’s the descents where it really lights up. Initially I was noticing the lack of a 240mm dropper but started getting used to the 210mm. It really flies. I get that ravenous fire in my eyes and just want more and all there is. Good stuff.

- I ended up keeping the 50mm stem but lowering it with the 3mm spacer. That was all I could do given the tall headset cap. I’m swapping that for a shorter type so that I can go down another 3mm at least. It’s a testament to my method that I can come this close in fit without every advantage in testing.

- The saddle it fucking horrible. I don’t know what it is, maybe I bought the wrong width but it feels like knives on my sit bones. I’m switching to the familiar WTB Volt Wide.

- The gearing range is a little narrow. I’m well centered but noticing on either side. I may need to move to a 10-52 cassette. Will also get a 38t chainring to play with.

- The handlebars feel totally antiquated. The lack of a wing top is pathetic. I prefer ergo bend bars and would like a shallower drop. The width seems fine but more reach would be good for climbing.

- The tires and tubes aren’t light but are utterly confidence inspiring and solid.

- I had the pump mounted to the seat tube but that got in the way of my leg while doing weird positions around town. I moved it to the down tube and it was fine. The clip held it fast without issue.

- The flat pedal pins were very nice. I felt like I had all the grip that I needed and they would be good for all day comfort.

- The chainstay is as low as it can go without interfering with the GRX derailleur cage when in the 10t cog. This is a pretty large cage section. On the next draft of the dropouts, I’m going to raise that up about 1mm for a little comfort.

2024-07-27 – Shakedown 2, Bofax to Alpine Dam and back.

Another test on Bofax. I had been thinking of the Paradise loop but that seemed lame. Still, weather was odd and it was looking murky and cold as we got close to the coast. My ass was still killing me from the day before but the Volt wasn’t making it worse. So we figured that we’d just go out to the dam and back.

I made a snap decision to start the ride with a 60mm stem. I’m looking for a better feel when climbing out of the saddle. Since I lowered the stem a bit more than yesterday, this was a significant change. By the end of the ride, I determined that this would be my most aggressive position. Old age does that to a man. I’m just not tolerant of that extreme of a setup here and I was just about loosing feeling in my hands as we road.

I was starting to dive in a bit harder on downhill corners. The tires feel good and planted. Geo is for speed. Still need to feel it out there but the longer stem helped me get a bit more weight on the front.

I’m really just chasing down a rub noise in the front wheel under heavy power. Probably just a caliper adjustment.

2024-07-28 – Shakedown 3, Bofax to Azalia Hill.

These rides seem to be getting shorter. Dang. I was really dragging today but I did some time in the shop to sort out the rub. The caliper was just slightly off center and the front wheel spokes weren’t as tight as I like them. I addressed both points and the bike is dialed. Dead silent even in the most angry of states. Now the bike is going into service, mostly for commuting to and from work. Such is the life of a road bike.

I nudged the saddle just a little more forward to help me dig out of the seated position when attacking climbs. I have some range to move back from this as well as room for a shorter stem with more spacers for longer easier paced rides. It’s nice that I have a setup that is pretty well sorted for adjustments like this.

Here’s the final setup print that reflects the bike today:

2024-08-01 – Shakedown 4, 3 days of bike commuting to work

I spent the first half of the week riding my bike (intermodal) to work. This gives me a lot of conditions, especially in San Francisco. Steep hill, wet roads, and hard braking mix every section up. With the 40mm tires, the bike was super nice and rock solid. Those tires do feel pretty sluggish along with the overall weight of the bike. Great feels, tough work.

I decided to swap the big tires to something smaller. Tires are WTB Exposure 622-30 x 700 Light/Fast 120tpi that measure 35.5mm wide on the i25 rims.

I also got quite sick of the feel of the Salsa Cowbell bars and was driven to order the Whiskey Spano 46cm bar. While this reduces my handlebar drop 15mm but most importantly gives me a wing/flat top to the bar. This should add significant levels of comfort.

Ever so slight changes to the print. I’ll be able to give both these changes a feel on Friday.

2024-08-02 – Shakedown 5, Friday bike commuting to work

The tire swap is nice. The bike feels a little crisper and faster. No idea what the actual numbers are. It’s just feeling better.

The handlebar swap is huge. I love the shape of the top wing on these. So much more comfortable than the old Cowbell. They have a subtle ergo bend which is helpful. There is some shaping to the lower bar which may be helping but almost makes a new hot spot. I did wrap some padding below my contact areas but that hasn’t mellowed this out much.

Now I need to do some more riding and figure out how I want to expand the gearing range.

2024-08-03 – Geometry Comparison

I figured that it would be interesting to look at a bike that others may be familiar with, the OPEN WI.DE. Here, size large.

I’m shoehorning myself into a large here and it’s still got a 61mm shorter front center than the Gulfstream. I could use a dropper but it would have to be 110mm or shorter and would have to be a crappy 27.2mm type. The 120mm stem is a decades antiquated choice. The cranks are 5mm higher and the rear is 16mm longer. Of course, this doesn’t have a UDH interface, so modern shifting systems aren’t compatible. More, you can’t even use a double chainring.

This is a terrible bike. A 56cm Specialized Crux is a far more advanced bike. It’s faster and has more room for setup options. I fail to understand what makes this bike a real choice.