I know a few things. After 51 years on earth I’d have to. Two of things that I know more than almost anyone I know is bicycle design and skateboard design. I’m pretty good with a couple other things. This is about skateboards.

Sadly, while I’ve been making some serious progress with producing some important innovations understanding bicycles, I haven’t done much with skateboards. I’ve cut a few decks and figured out a few cool setup details in the past five years or so but it’s been 20 years since I produced the PVD R3 trucks. These are still the most cutting edge and innovative racing skate trucks ever produced but that doesn’t do a lot for kick around boards that I actually use several times a week.

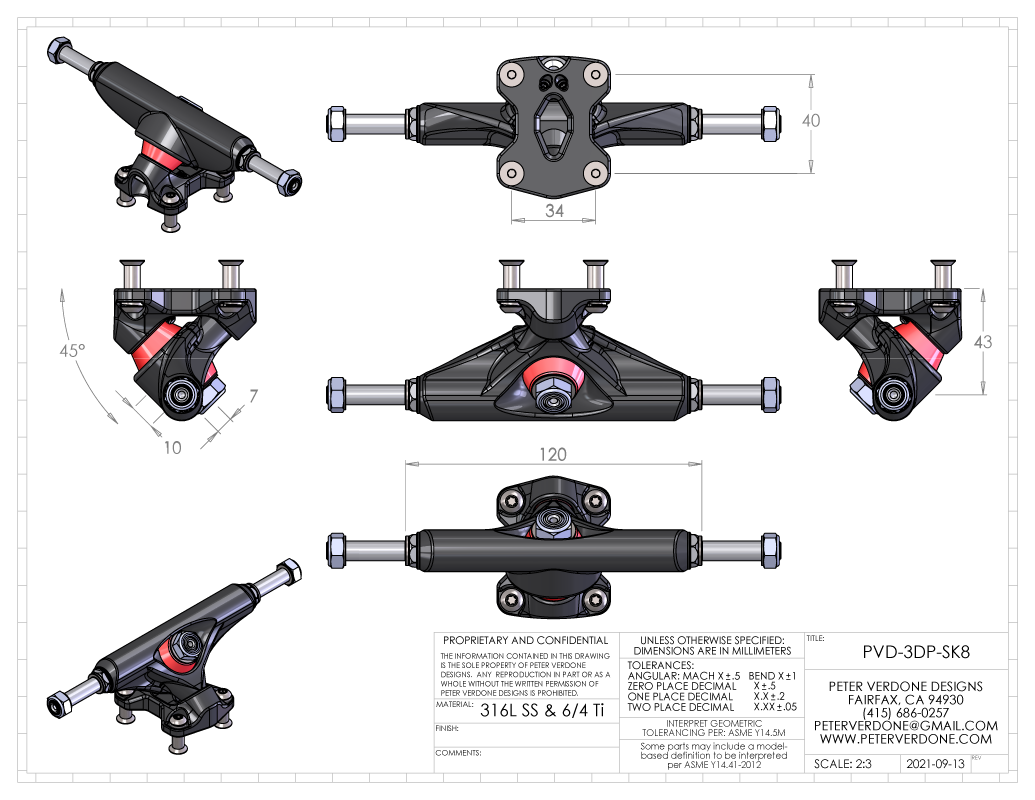

While others have cut trucks from billet over the years, very little has been done developing skate trucks since I last did. The time has now come. The designs shown here are preliminary designs for a new cruising truck. I’m hoping to start ordering the parts this upcoming week.

The goals for the project are pretty obvious if you know my work.

- 120mm truck hanger width for a deck width of 185mm.

- 45 degree steering angle for a wheelbase around 485mm.

- 43mm truck height to keep the deck top low, especially when used with 64mm and 66mm wheels.

- 42 degrees of pivot span producing 15 degrees of deck tilt and sub-meter turning radius for great high traffic sidewalk navigation.

- Turn limit adjustment system for maximum turn and safety

- Precision 8mm axles and spacers for skateboard or rollerskate spaced wheels.

- Titanium hardware throughout for light weight and corrosion resistance.

- Very precise and tunable steering feel options with Riptide APS Cone bushings, 0.5″ top and 0.6″ bottom.

- Compact footprint and elegant presentation.

- Super lightweight design from traditionally produced parts.

The hangers and baseplates will be printed in stainless steel and the axles machined by CNC.

The design of the pivot system makes use of geometric properties to produce a progressive feel in the action.

Turn limit screws make it possible to use extremely loose setups or very aggressive riding technique without the risk of wheel biting. This can be seen as a safety device or a performance feature. Regardless, this allows the truck to work in a way unlike anything else.

A few years ago I did some work with producing wheel wells for these types of skateboards. I was able to get something usable and good from a traditional sense. For these trucks, I want to move to another level. As I’ve improved the modeling of the wheel well cuts in the decks, I can now get a crappy desktop CNC router for a few hundred dollars and actually surface mill them into the boards. This will give me more space for turn without removing any more material than is needed.

I’ll also need to make an updated drilling fixture for the modern mounting hole pattern and hardware I’ve designed into the assembly. This should be pretty basic but the 6.5mm drill bushings add up in cost.

If all this goes well and I remain excited, I’d like to produce some very lightweight and waterproof carbon fiber decks of a similar shape. This is a whole new level of carbon work and engineering for me so I wouldn’t expect to do this for at least 6-8 more months…if I do at all.

Please don’t bother me about buying these. They are not planned for sale.

Anyway, it had been a while since posting here and I wanted to share what’s been going on.