In the world of flat bar all-road bikes, it’s certain. Bar-ins are REQIRED for performance riding. I wouldn’t have been this absolute a few years ago but it’s now become the primary hand hold on my bike. Facts are facts. When covering ground that isn’t extreme, this is the more relaxed and efficient position for me to be in. It feels good. It’s more aero than in the grips and my wrists get a bit of a break.

The magic of the bar-in is that using them has no effect on downhill or technical navigation on the bike. I’ve had zero issue with them regardless of the conditions that I try to squeeze my bike through. It’s a small weight penalty but real gains for huge parts of the ride.

For reference, the mounting lugs are 510mm apart here.

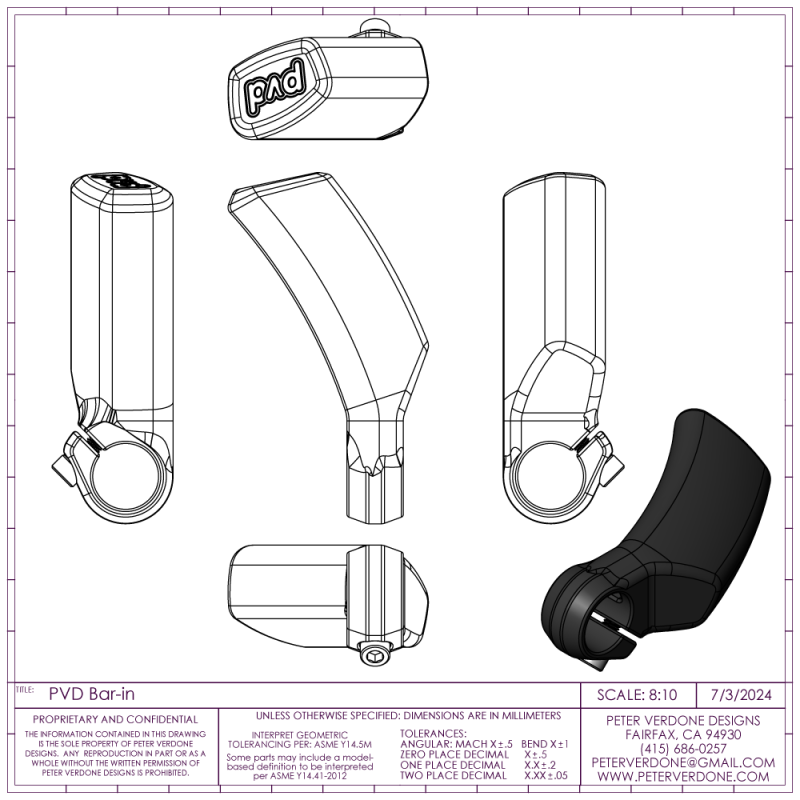

I’ve shared some of my preliminary work for a bar-in design over the last few months. I’ve done some basic testing with a commodity bar-end and then with some 3d printed plastic to sort out some basic geometry. That can be read about on another posts. Work was done but it was time to move the project forward in important ways.

The restrictions of using existing parts meant that the geometry was nowhere close to optimized for the 16 degree sweep and 20 degree roll of bars that I’m currently using, not counting real comfort goals. The bar-ins needed a much shallower sweep and some profiling to work better with the hands. The broad tops that were tested proved wonderful for reducing hot spots and this needed to be increased in a more solid way.

Ok. These are the first prototypes for this concept. I wasn’t trying to make a totally finished product. I may get them powder coated but am waiting for a black color run.

The prints turned out nice enough. They are lower profile and look a lot better on the bike than the testing versions. Still, they are slightly short. The shape is pretty good but needs more work. Maybe 5mm more length would be good for the grip. I think that they could be a little more broad. They’re also on the heavy side as they are made of stainless and on the safe side.

I thought of a couple of interesting tricks for bringing down the weight but only after ordering the prints. Hopefully, they will get down a bit for the next round and maybe titanium will be a good choice. The priority for this round was to get something up and working so I now have that.

More than anything, I got a better color wrap on the new parts. It looked horrible during testing but I didn’t want to waste what little good tape scraps that I had on parts that were just rough prototypes. Now I can allow for more investment there.