There are a few options for holding workpieces and tooling down to fixturing weld tables. I’m going to skip the most common types.

Since I’m trying to build out precise tooling in this ecosystem, there a few ways of doing this that I’ve realized that solve in quite a few scenarios.

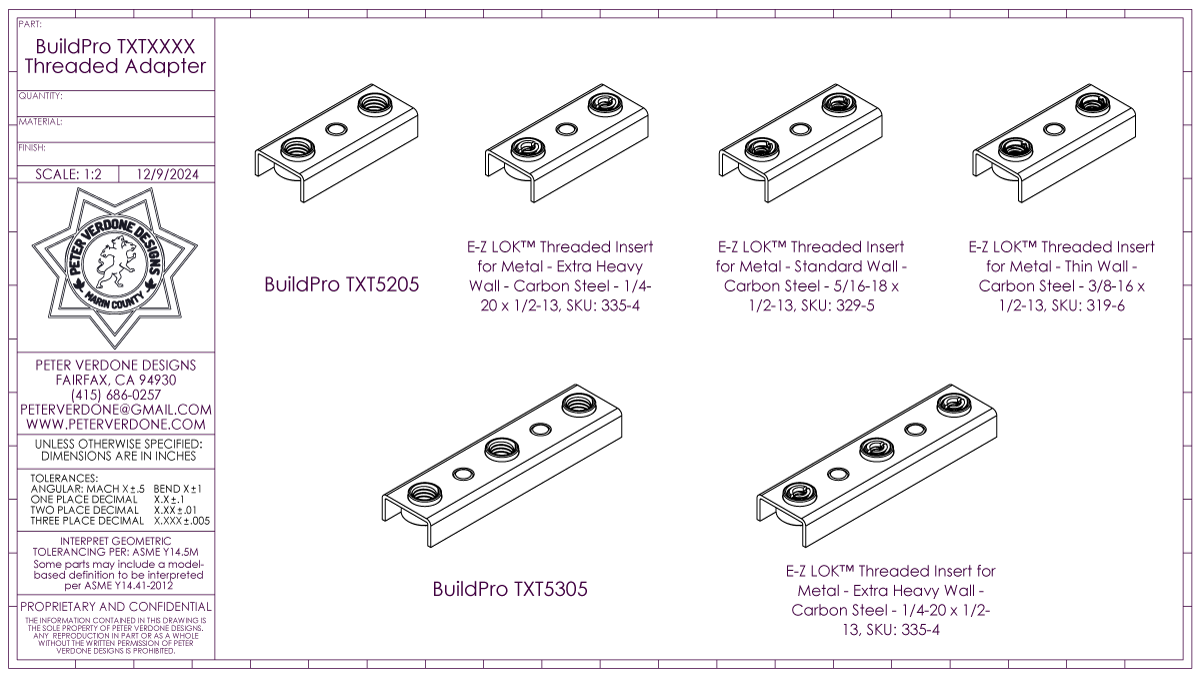

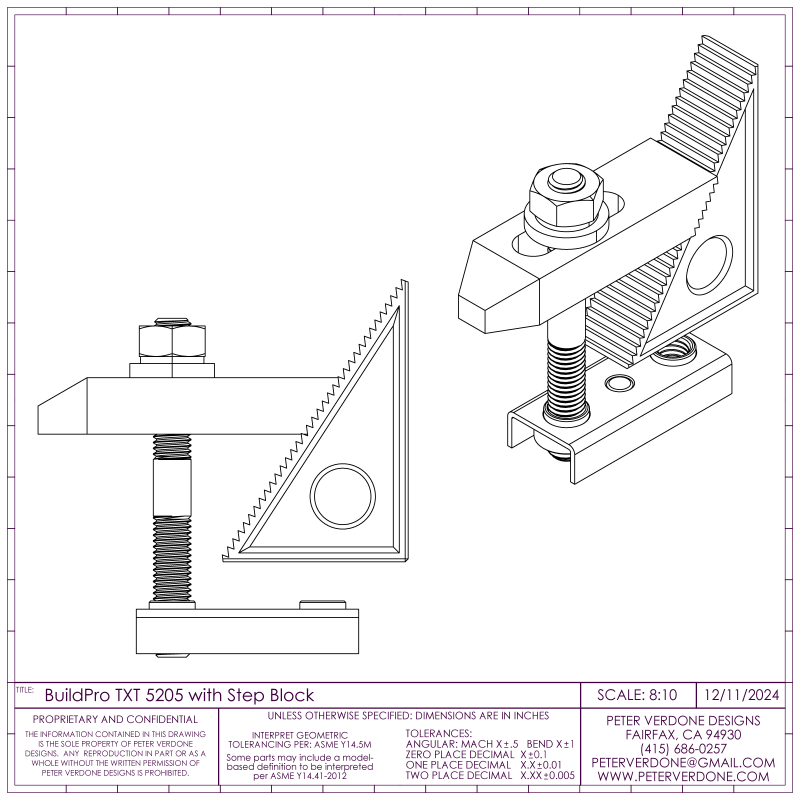

The first step in having options is by obtaining a few BuildPRo TXT5205 & TXT5305 with a 1/2-13 thread. These are relatively inexpensive, $7.80 ea. They make life easy and a lot of things possible. I prefer the double (TXT5205) plates as they are a little cheaper and fit into a lot more scenarios than the triples. I’ve cut most of the triples that I had down to doubles.

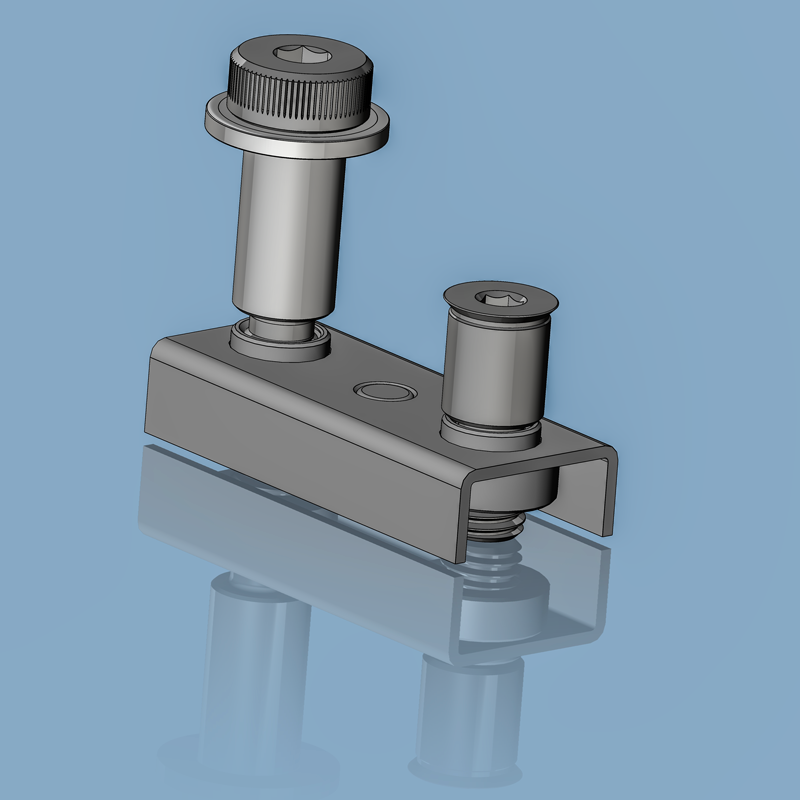

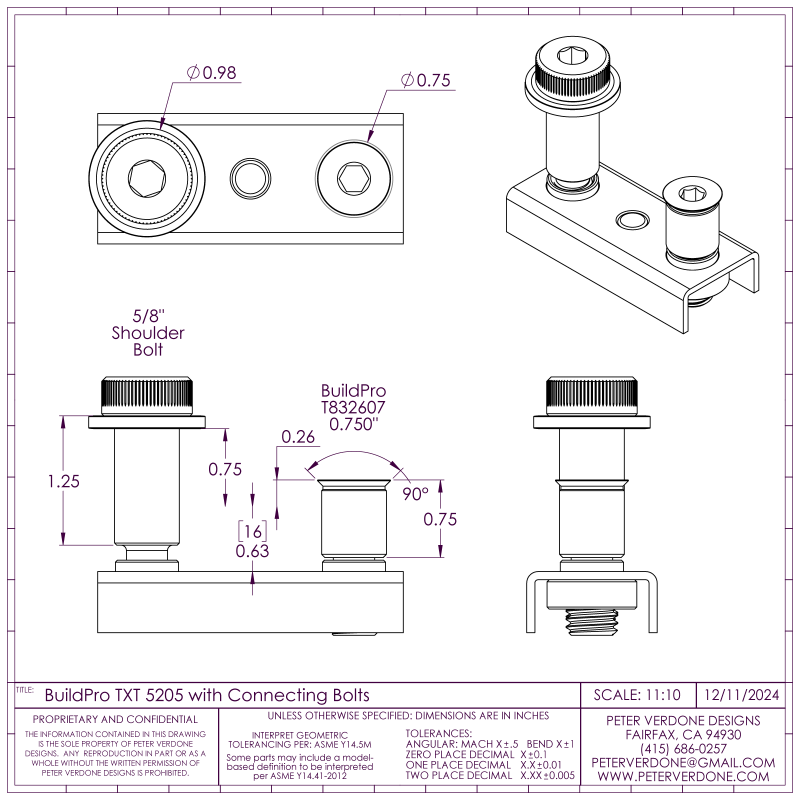

The plates hold to the back side of the fixture with small magnets. A proud section locates the threaded lugs directly beneath the various table holes. This eliminates the need to fuss with nuts and washers on the underside of the table. It’s dam simple.

It’s important to purchase adapters with that particular thread as it will give the most options for fit. We use threaded inserts from there to step down to the smaller threads. There are many EZ-LOC inserts available for the 1/2-13 thread. HERE is a list. Changing them around is quick and easy.

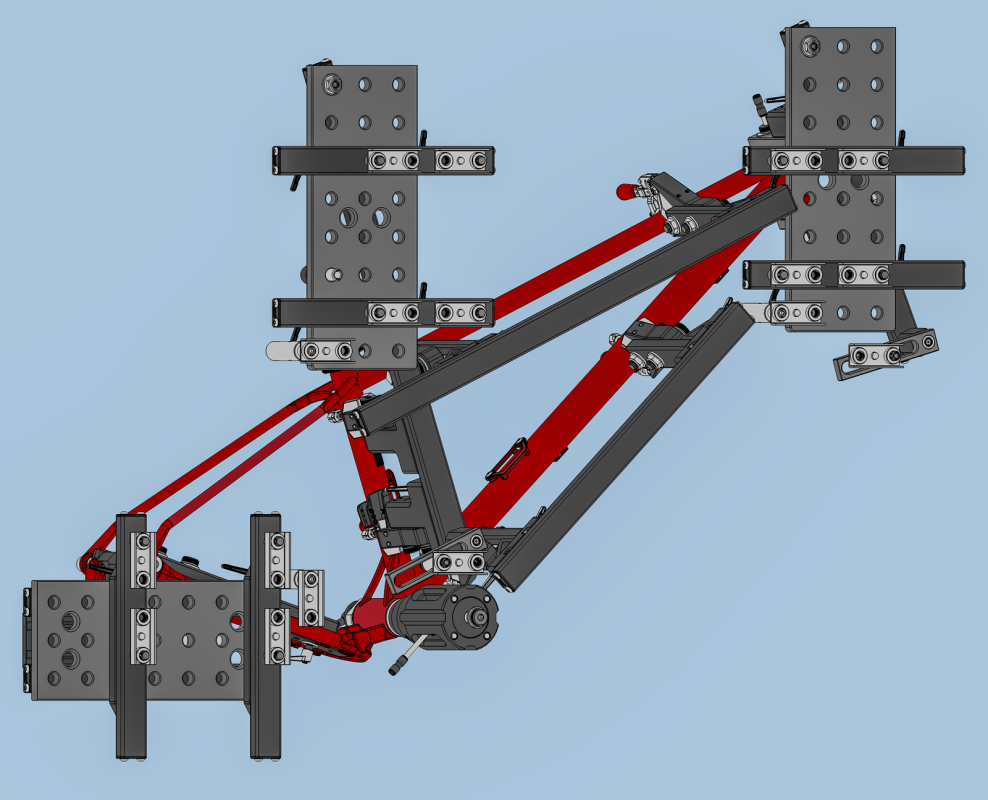

These little plates are very valuable and important to have. You can see here that the Samantha Frame Fixture uses seventeen TXT5205 in a basic assembly.

The real magic here is that 5/8″ shoulder screws have 1/2-13 threads. We will most often use 5/8″ shoulder screws when clamping tools down to the fixture table. This provides a very strong and precise fit for alignment of what is needed. Sometimes, a 90 degree countersunk shoulder screw is needed, like when mounting 8020 rail. BuildPro has these on hand for just this case in the form of their “Flush Mount” shoulder screws: 0.75″ (T832607), 0.875″ (T832608), 1.00″ (T832610), 1.25″ (T832612)

A setup that you don’t see too often is machine shop step blocks. Most machine shops have a number of setup block components near the milling machine. These same components that are typically used along side the t-slot of a milling machine table are just as useful on a fixture table. Extend the value of these tools! Ensure that the threaded rod is 1/2-13 and you can do as you please. Gibraltar & TE-CO Tooling has all kinds of options for this. Hold down clamp parts are available at McMaster-Carr.