Careful readers of my blog will know about the ‘bean can’. It’s a simple enough device that protects the delicate top tube of a bicycle frame when proper hand grip placement may produce damage in a crash. When everything goes ass over tea kettle, the front end swings around wildly, looking for something to stop against. If that’s the shift levers, brake levers, or even the bar end against the top tube then that’s what it’s going to be. Metal frames can be dented. Carbon frames destroyed. It’s bad.

These show up on my bikes from time to time. I came up with it a very long time ago. In fact, I first posted about it in 2013, 9 years ago. Still, most folks are happier destroying frames in crashes or ride with incorrect hand grip placement than apply this solution.

Early versions were exactly as the name states, a cut up corrugated bean can. Over time, I started using cut steel plate, stainless steel coupons. Just before this, I was trying thin aluminum.

These had become very elegant and simple enough to produce…for round tube bikes. On those bikes, I can just bend some metal over a form and it’s done. On shaped carbon fiber and hydroformed aluminum top tubes, it’s a pretty complex bend to do at the level that I demand. I had got close in the past but not in a way I would brag about.

So, I had posted about Windy’s new bike on a PinkBike forum to show off the neat bike it was. A user, eshew, brought up the bean can and suggested using Kydex thermoplastic (thermoplastic acrylic-polyvinyl chloride). This is the same stuff that a lot of modern formed holsters, sheaths, and tactical trickery is made from. Sekisui Kydex (PDS)

It was immediately an idea worth trying. The question, how thick will be required to offer the protection that will be needed? We want it as thin as possible to look somewhat decent on the frame. Even thin plastic is going to be a lot thicker than the metal that I’ve been using.

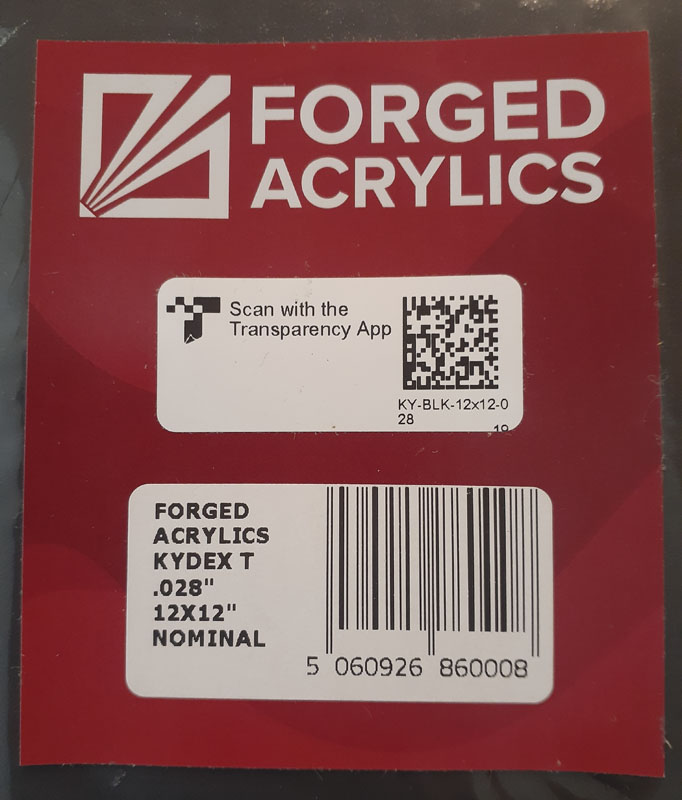

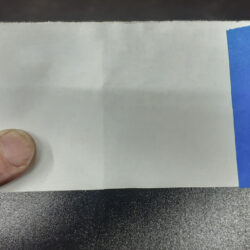

I ordered some 0.028″ and 0.040″ sheet from Forged Acrylics for options. Looking at what I had, I decided to take the risk with 0.028″. I’m hoping that it was the right choice.

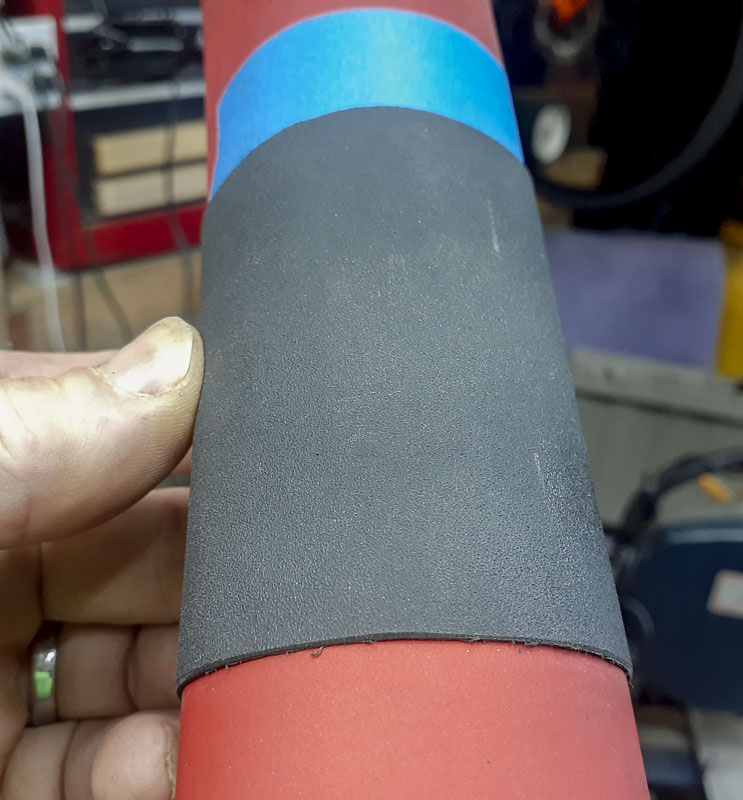

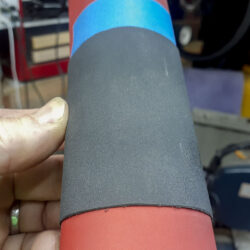

I prototyped the size I’d need with some cut paper. That gave me good information for what to cut from the sheet with little waste. With some tape, a heat gun, and some time, I was able to form the plastic very precisely to the carbon top tube of this bike. I’m sure that there are better ways of doing this with a hot pad and pressure but this was my first. I’ll get to something cool later.

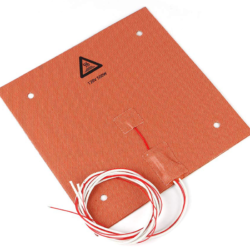

I was very careful to not overheat the carbon fiber of the frame while working with the heat gun. The last thing I want to do is upset a critical material balance with some unusually high heat. I figure that a decent silicon heater pad pressed against the Kydex with a thick rag between should produce excellent bends on complex surfaces. The sheet needs to come up to 165-177°c (or 330-350°f) but this seems a bit high compared to what I was doing. Something to try next time.

Before taping in place with PVC electrical tape, I took the part to the belt sander to soften the edge. I also slightly trimmed the plastic at the seem as it does stretch as it forms. It’s also laying far better than the paper.

The Kydex bean can turned out excellent! It looks far better IRL than in my photos. It fits so snug to the tube, even with my novice skills. If the 0.028″ provides the protection, this is the way to go.

A little show of the utility of the bean can. This shifter will cause some damage without the bean can. With it, it my be fine.