I’m not good at leaving well enough alone. I get these itches and all I can do is keep scratching at them. I keep doing the work long past when the first round of payback is had, maybe getting to more unforeseen value. Everyone else gets to benefit from that. I just keep suffering.

As discussed in the previous post and others, lasers aren’t very good for high levels of precision on the fabrication table. That had me chasing for better methods and manners for solving the calibration problem.

Lasers are pretty handy though. It’s nice to have a little green dot to locate a point in space.

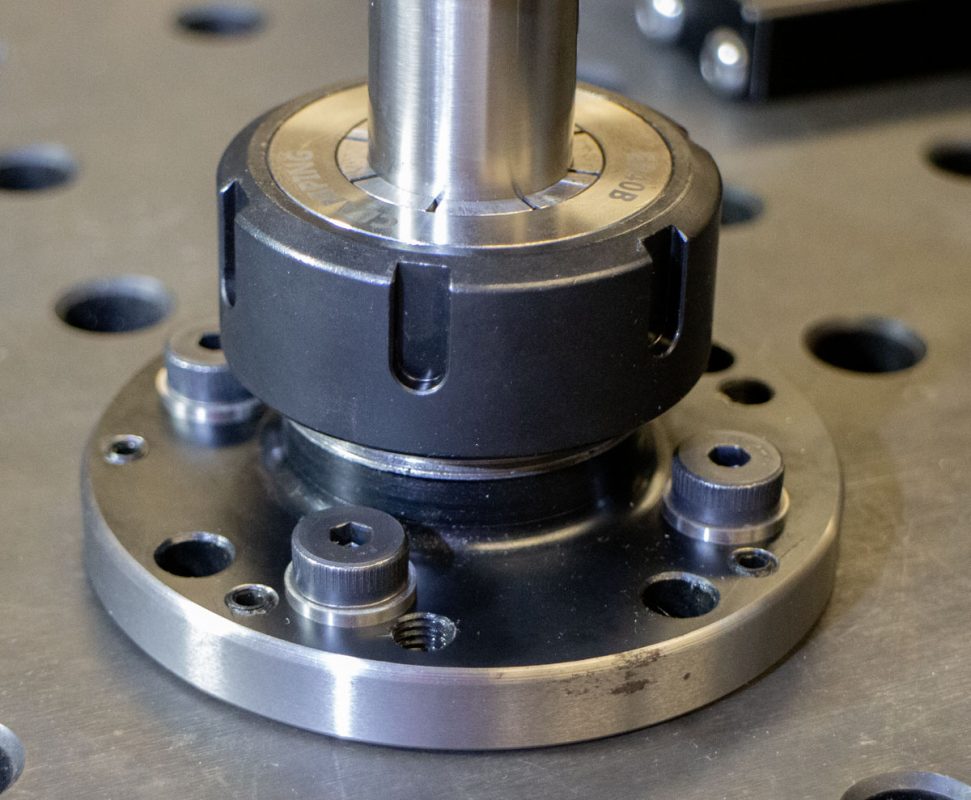

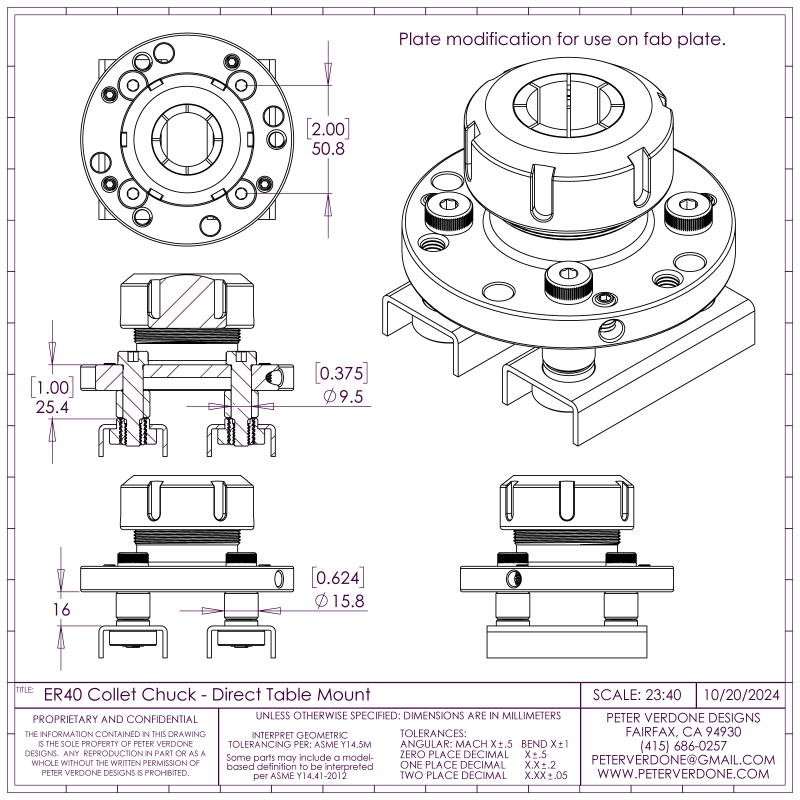

To that end, I found a way to modify the ER40 collet chuck for use directly on the fixture table. This uses shoulder bolts and sleeves to keep a fairly tight control on position and has 4 calibration screws in place.

This gives me the ability to mount a vertical shaft of any diameter (up to 29.5mm) centered between the holes of the table raster. I can mount my laser scope to it at the height of the center plane or any small holding fixture. This can make for a quick but precise setup at some point in time.

In time, I’m hoping to discover new and different ways of leveraging this option. This is an incredibly rigid interface. Not the very most but pretty amazing considering the pillar diameter can be changed out to almost any size in less than a minute.

To fit the fastening elements, 3/8″ shoulder screws are located on 2.000″ centers. Bushings align them in the table holes to locate the plate very specifically. Then the bolts thread into BuildPro TXT5203 loaded with 5/16-18 threaded inserts from E-Z LOK (329-5IC).