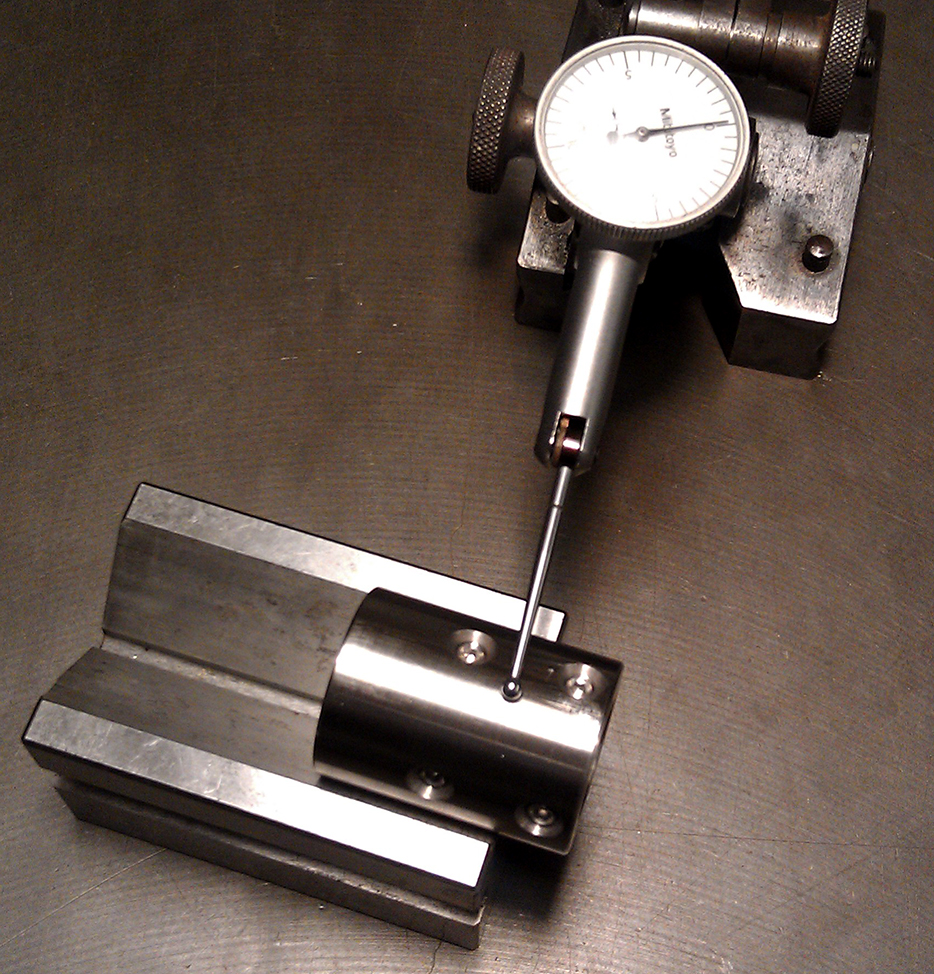

I made a neat little spider chuck. It’s for machining the bolt of the 308AR for accuracy.

A spider chuck allows me to locate the bolt exactly according to the several features that I decide are important regardless of the shape of the part. Since these parts are forged and then machined in very elaborate ways, it’s very difficult to reference and hold typical and easy ways.

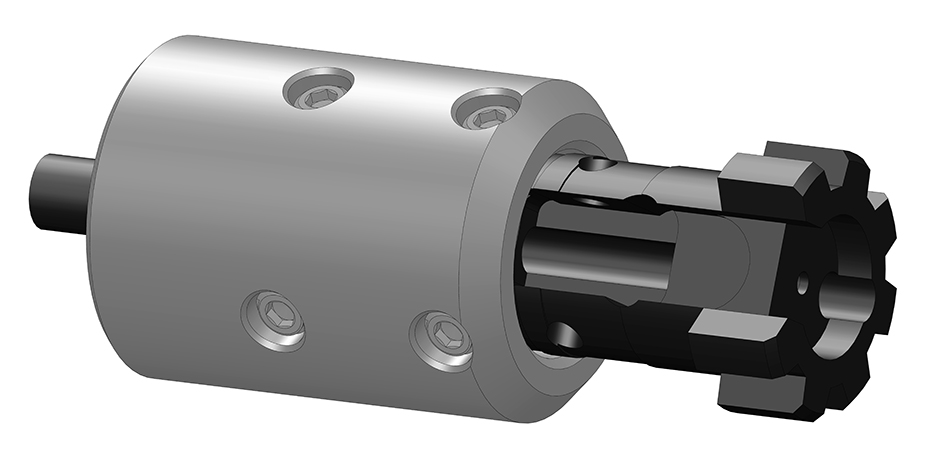

This tool is machined from 1.125″ ground 303 stainless steel shaft, 1.5″ long, with 8 stainless steel flat bottom set screws. It fits perfectly inside a cheap 1 1/8″ 5C collet that makes accurate machining very easy on the Hardindge lathe.

Later I’ll make a larger version for working with rifle barrel breeches and muzzles.