The other day, I was having a conversation via Facebook with an old friend, Dave. We were talking about something having to do with his new bicycle. This and that. At some point, he flashes a picture on the message saying “Hey! look.” I was blown away. A world from so long ago…

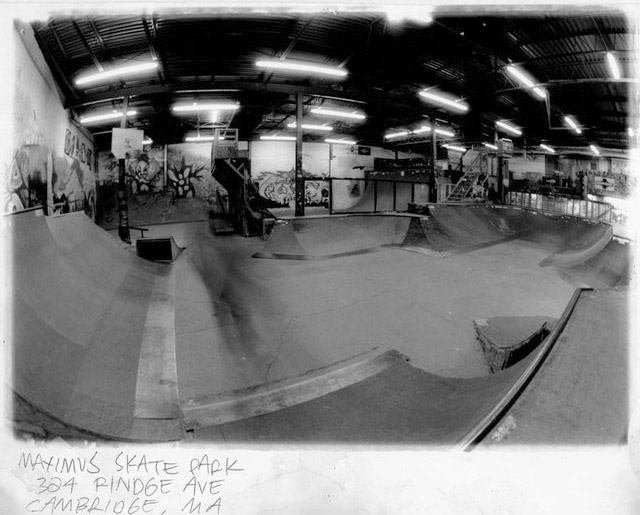

It was an old pot pipe. Eighteen years old to be exact. I know. I made it and a few others for friends around 1994. That was back when I was one of the guys at Maximus Skatepark in Cambridge and working as a CNC machinist in Arlington Heights. Maximus was an incredible place. Magic. A place where the lost boys could go. An island in the ghetto where our rules were the only rules. Of course, in addition to some incredible skateboarding and mischief, a lot of pot was smoked. Special ‘safety’ meetings were conducted in the parking lot that quite a few people are lucky to remember. A clubhouse in a crazy world.

I don’t smoke any longer but I did back then. Kenny, the former owner, was known for his brass ‘modulator’ bats that he’d make and number for the homies. I had been making water pipes since I was about 15. Early versions were rudimentary but after 7 years I had some real ability and discussions with Kenny over the years had taught me a lot about fabrication, metal work, machining, and of course smoking pot. I really learned a lot from Kenny. I think a lot of people did. It was like it was cool to think for yourself and use your brain for something. Very good stuff. RIP.

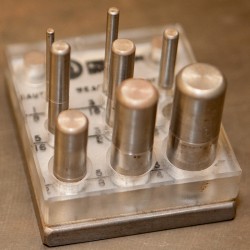

Of course, in time any good student has to show that he is now the master and that there is a new school in session. 1994 was my year. At work I had millions of dollars worth of tooling to play with and real master machinists teaching me their craft. In this world it isn’t enough to know how to make something, you need to know what and why you are going to make it. I knew that a run of titanium pipes with my design details would put me on the map.

A few years earlier I had been working at Fat City Cycles making some pretty wild bicycles for the time. Fat City was a pretty amazing place but that’s another story. Anyway, one day after work Gary Helfrich stopped by and of course that meant that some pot was going to be consumed. Gary IS titanium. He pulled out this titanium pipe that had some styling ques from the clay tavern pipes that had been used during the early American settlements. This caught my eye as I grew up in Lexington, MA where the American revolution got it’s start. I thought it was really cool but it had some design problems the way he did it that I didn’t like. I later made one on the manual lathe and welded the stem on. This was a great pipe that sadly was stolen from a visiting dirt-bag at Maximus a few years later.

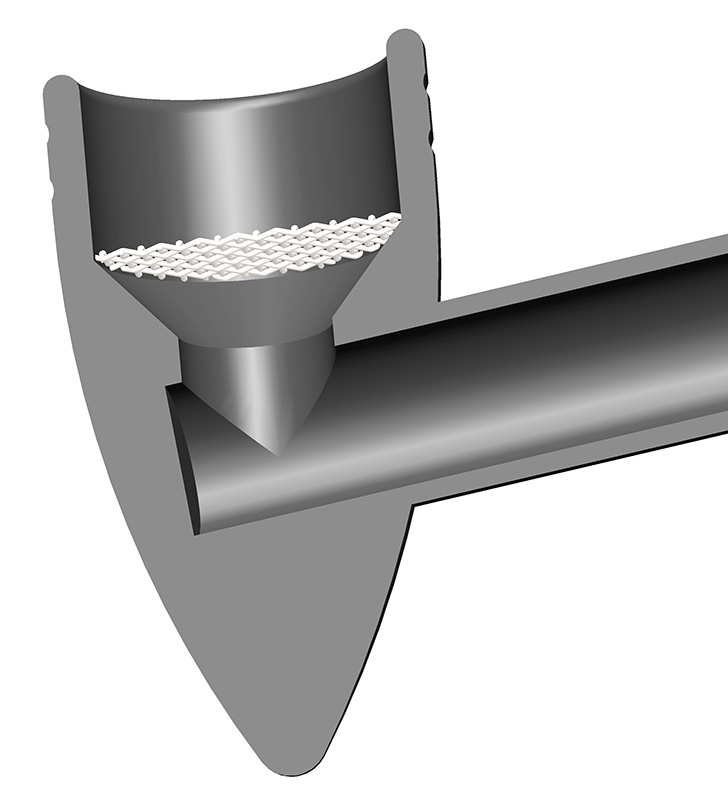

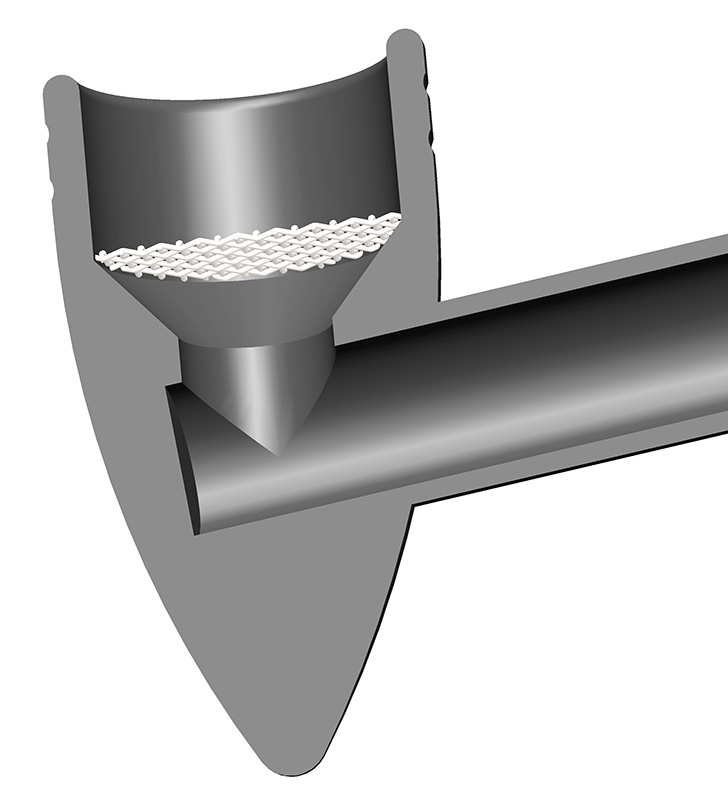

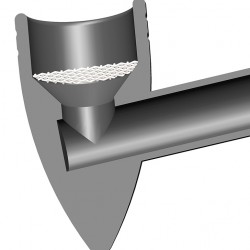

As a machinist, I learned that I actually had to do math. I had really sucked at school growing up but now, with a real meaning, I could command the numbers to do my bidding. I sat in a cafe for a few hours while I taught myself trigonometry, or at least enough to get this designed. The shape of the bowl being that of a spherically blunted tangent ogive, like on many bullets or nosecones (remember, most of us had no idea about this Internet back in 1994, thus no Wikipedia). With my math done, co-ordinates plotted, program written, and material purchased the parts were then cut on the Hardinge CNC chucker. A few operations later and the stem was press fit into position. Fabulous! Polish ’em up and burn…

Of course, there were details of the original ‘manual’ pipe that didn’t come across in the sano CNC versions. Below is a print of where I would take the design next time I do something like this. Essentially, the bowl needed more elongation and the stem needed to be longer. This design may not even be enough. I wish I had that original pipe to measure from.

The real art to this design is the conical area below the pipe screen. This is important in pipe design as that feature is what allows for a full even burn of the pipe’s contents. The larger this area the better.

A few years later I saw some pipes similar to mine that had been made by Mark at Paragon Machine Works. They were ok, but I like mine better.

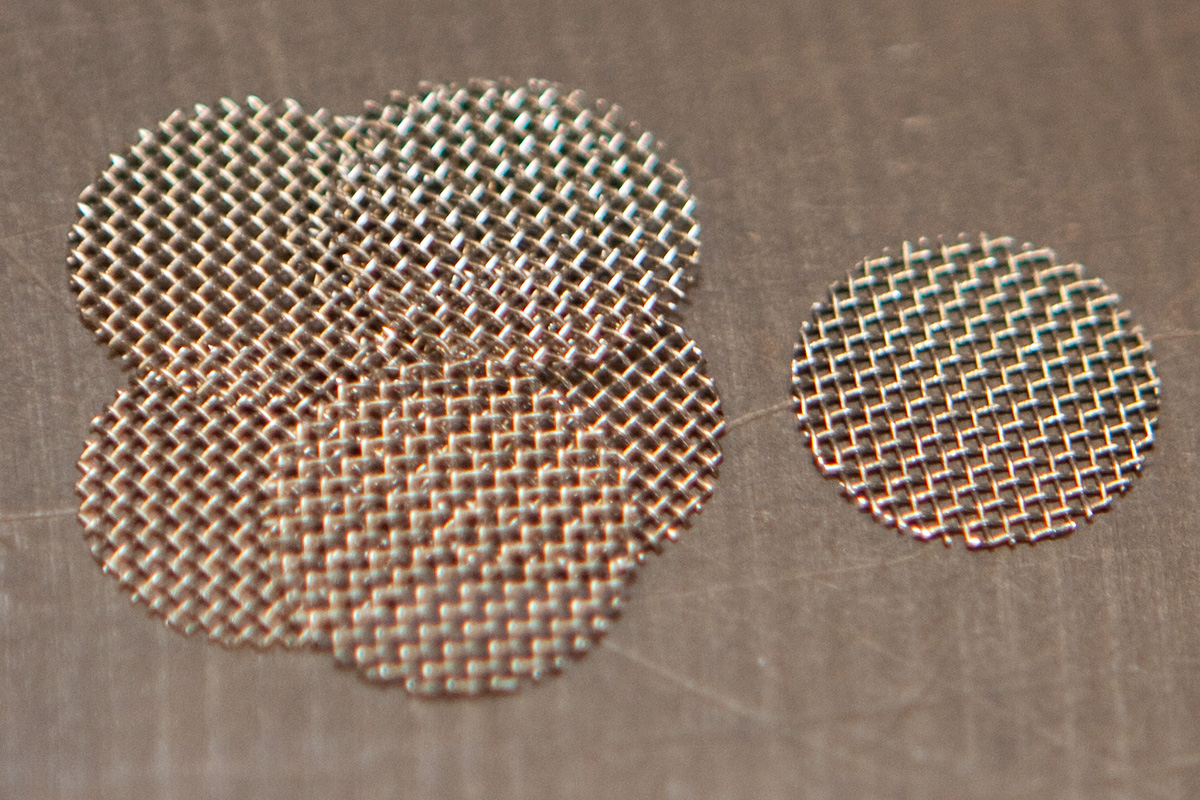

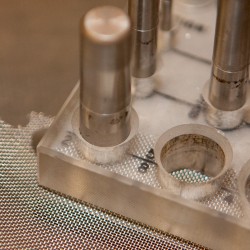

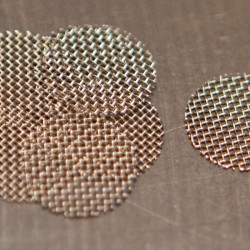

After years of making pipes, I had perfected the finer details of their design. One of the most important of these is the screen. I had ended up cutting my own screens as anything available commercially is just not suited to the task. The mesh has to have just the right size gaps to prevent clogging but also prevent ash from passing. The wire needs to be strong and thick enough to handle multiple heating cycles at very high temperatures and also be scrapped clean with whatever is found around and not tear. Brass is completely inadequate and the standard stainless steel screen from a pipe shop is flimsy and clogs almost immediately. I source 304 stainless wire cloth from McMaster-Carr. Mesh Size: 32×32, Wire Dia.: 0.009″, Opening Width: 0.022″, Open Area: 50.9%. Cut to size using a special shim cutting tool so that they are super nice.