I’ve discussed (2) some of the particularities in additive metal manufactured parts in my bikes and skateboard designs.

It’s strange stuff. Since it isn’t (in a macro sense) a uniform homogeneous crystalline structure, it has some strange failure properties. It’s globular. I think of it like Styrofoam. It’s quite stiff and strong but when it fails, it goes quick.

Something just came up that is new in my learning about additive metal, gas permeability. This is the first time that the problem has been this obvious.

My new PVD M2-F2 All-Road bike was getting powder coated and I was waiting to pick it up. It had an hour to go so I went to the Costco around the corner and picked up a few things. As I was starting the car to head back to West Coast Powder Coating, AJ rang my phone. “Hey Pete. What the hell are those cast parts made of?” I told him that they were DMLS printed from stainless. He told me that we had a big problem and I headed there to see.

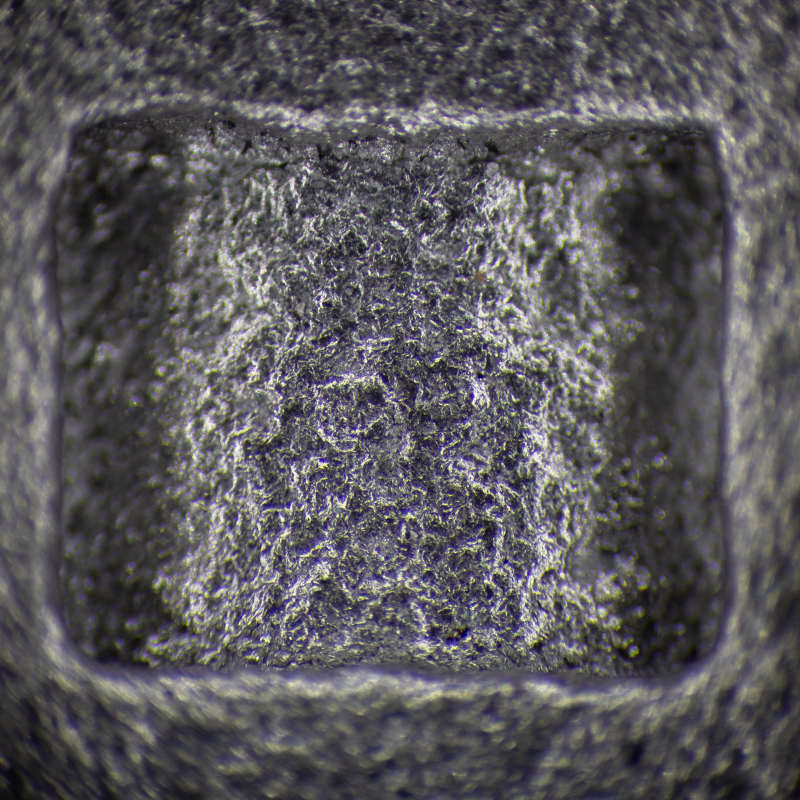

We went to the frame, still warm hanging on the rack by the oven. It looked like cancer. This was bad. All kinds of bubbled clear coat on some of the printed part areas.

I had seen little bubbles on my finishes in the past but figured that it was a pinhole in my weld or some contamination in the area. This was the same thing but at a whole different level. All over.

As an old Fat City Cycles guy, I look to seal tubes from the environment when I make a frame. This prevents water from getting in and rusting the bike from the inside. It’s also just a high quality way of doing things. Never has this been an issue unless a joint has a pinhole in the weld. It was only the areas that were sealed that had this issue. The parts that had ambient pressure on either side came out fine.

I took the frame home overnight and drilled some hidden 1/16″ vent holes for the parts. This was a lot of running around for me and a ton of extra work for the guys at West Coast. They stripped the frame and re-shot it. That produced a perfect coating.

So, venting and a ‘slow bake’ did solve the problem for this coating.

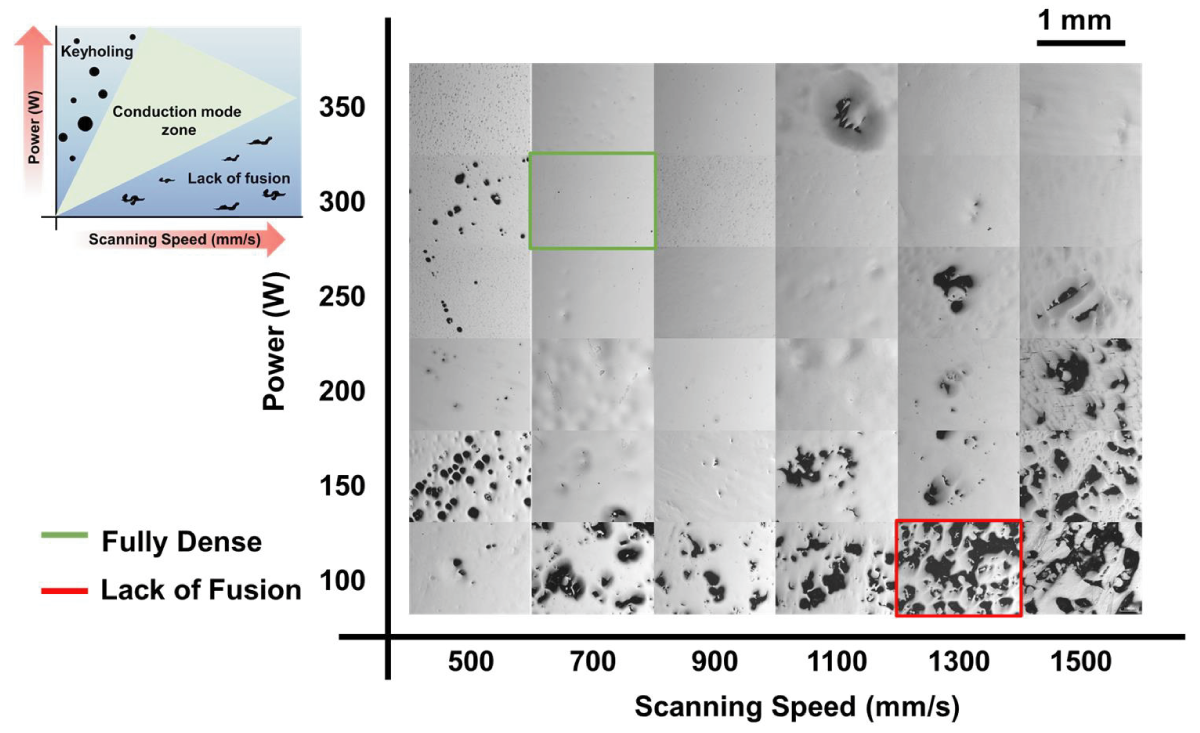

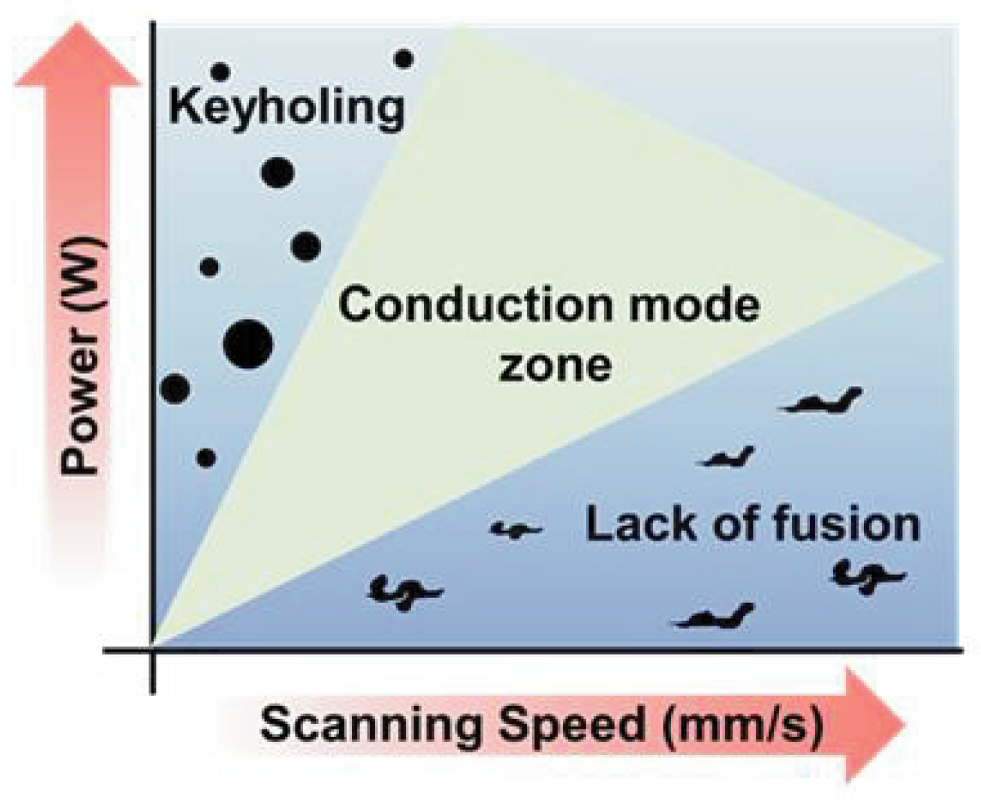

It’s clear that anywhere that sections of the bike were sealed from atmosphere, the printed parts allowed the heated pressurized air inside to release through the prints while the polymers of the coating were still liquid and as they cooled. I’m sure that there is a considerable pressure differential here but to have gas pass through what should be a ‘solid’ steel structure is insane. It’s not off gassing, it permeable material.

Usually, when talking about quality printing, we look for 95% fill or greater, but that assumes true fusion. I feel bad for neglecting to weigh these parts (as I have done for everything in the past) prior to assembly as that would tell us something but if the quantity of material is in place but it is not cohesive, what then?

This is extremely worrying and continues to be debated among folks that I associate with. Are these parts what we believe them to be? Are they as safe to use as parts that don’t exhibit this issue? Am I going to fucking die riding this bike?

Here is a good article on this subject: Lack of Fusion in Additive Manufacturing: Defect or Asset?

I’m still looking into this and will update this page as I learn more. I’ve contacted my printer.

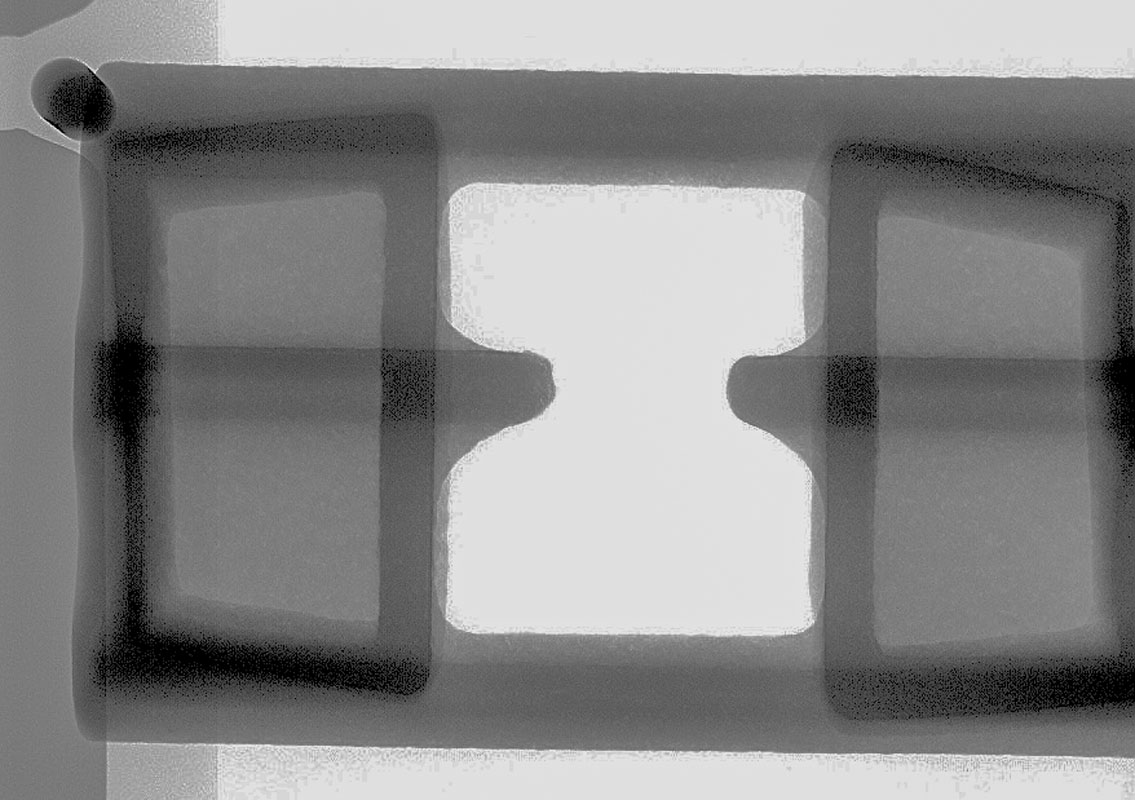

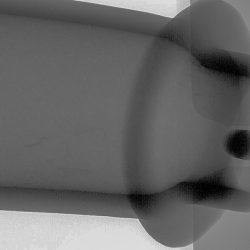

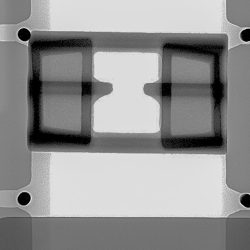

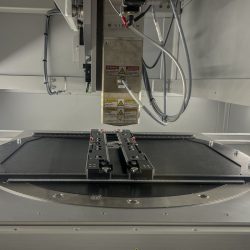

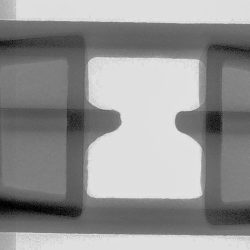

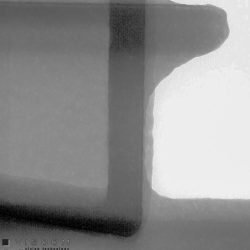

In the meantime, we had a few of our printed parts x-rayed to see if we could learn anything. We simply didn’t have the resolution required to find voids of the size we need in this case. It may be time to cut one of these parts and get it under a serious microscope.

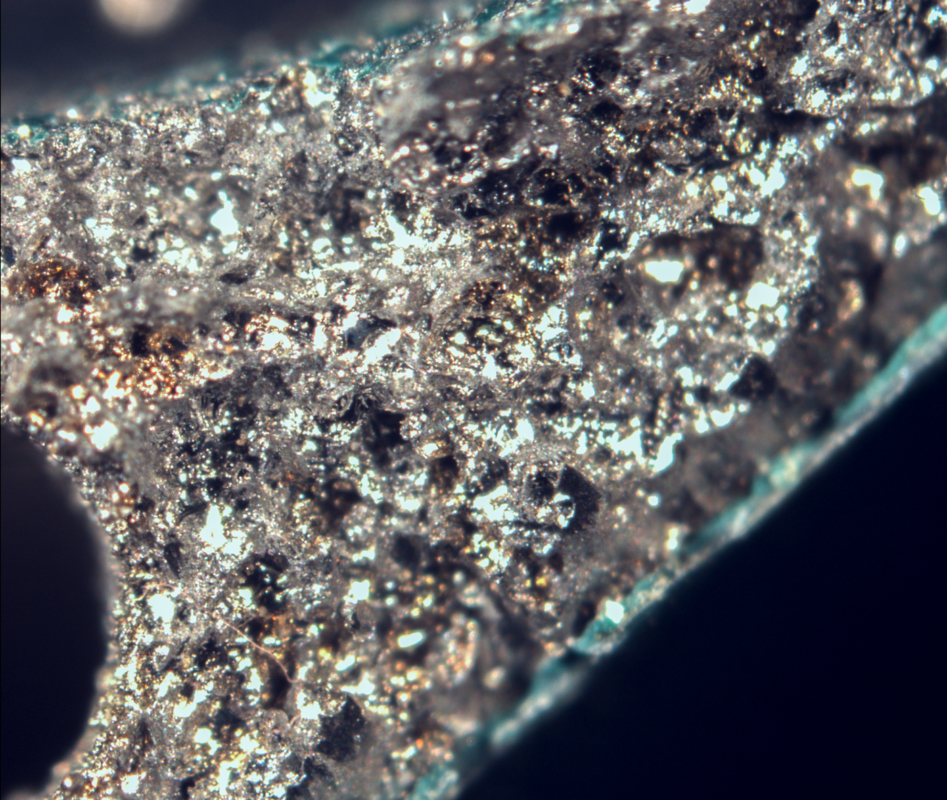

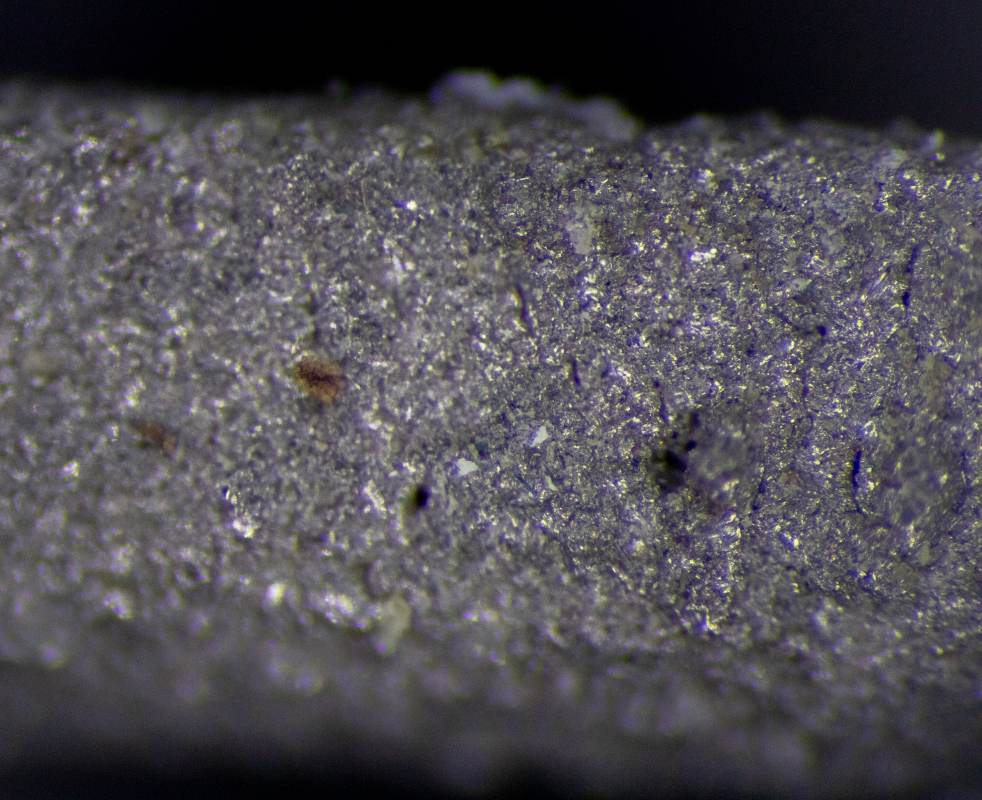

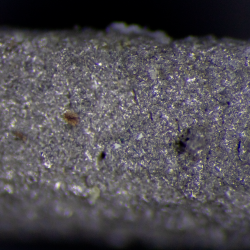

90x on another part. My first time looking for decent pics from the new microscope kit so bear with this image. Still, the surface is terrifying…even worse through the eyepeice.