So, I ordered up a nice little 22lr rifle to reduce my shooting costs and light enough to practice some off bench shooting. It’s a Ruger 77/22 All-Weather. It’s a gun slightly more expensive than it’s competition, but it’s got a great reputation for use, it’s made in America, and it looks awesome. Plus, it’s super light (6 lbs) especially compared to my AR-10 (11 lbs).

While I wait for the 10 day waiting period to expire, I was able to get the bolt, magazine, and scope rings from the gun to play with as they are not the numbered action.

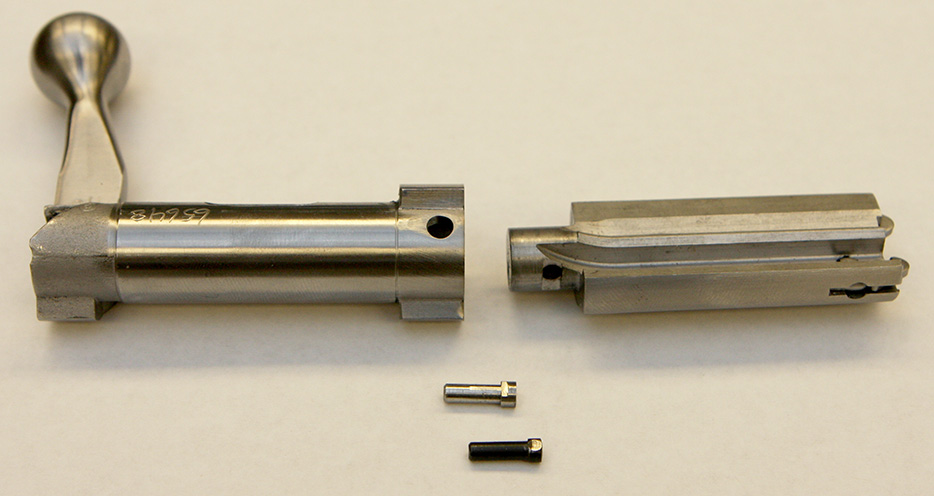

The bolt on this gun is a two piece type. It’s known to work well but can have issues.

In stock form, the two halves allowed for about 0.030″ of play longitudinally. That’s lousy. It makes the gun feel rickety and cheap and it also allows for inconsistency when cambering resulting in reduced precision. Note: Precision vs. Accuracy.

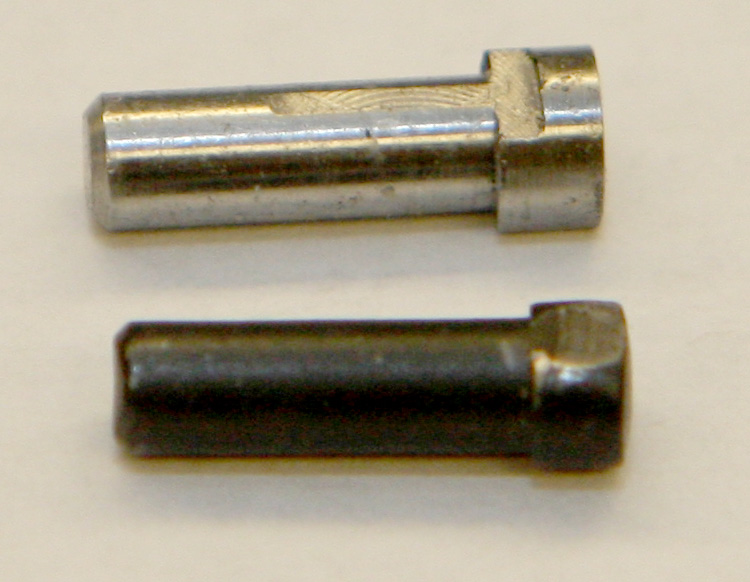

There are two commonly mentioned solutions for this. One is to shim the halves. This isn’t a great choice as any additional shimming will reduce the headspace at the chamber. The other solution that serious gunsmiths will use is a specially made guide pin to replace the stock guide pin. This pin has additional material on the guide side that pulls the two halves together without changing headspace and giving the bolt the strongest structure under fire.

The replacement pin reduced the play in the system from about 0.030″ to 0.002″. That’s a massive improvement. It will be nice to see what this translates to when finally shooting the gun.

I made one of these pins from some scrap stainless steel (3?? grade) that I had around the shop. Once I’ve tested the design I will make a new pin from some hardening tool steel for long life as this is a wear part.