I had a problem a couple of weeks ago. I was coming off of a ride on the M2-F2. What developed through the ride was a feel coming from the cranks that was horrific. It was grinding and feeling lumpy as I pedaled. I was lost as to what it was. I put the bike away and spent some time on the Millennium Falcon. I just wasn’t interested in fishing gremlins.

That was until I got eager to ride the M2-F2 again and test the new bar-in shapes. So, now forgetting about the issue, I took the bike for a ride around town. Again, lumpy grinding. Can’t focus on development. Ugh. The hunt for the gremlins started in earnest. I even chatted with Henry at Splitrock about what might be going on. We were both at a loss.

So, as I dug deeper in the shop, I found the issue. The drive side BB cup was loose. It had been tightened but that seems that it wasn’t enough….or I just fucked that up entirely.

This is where the wrench comes in.

I had been using the typical socked type 52/16 tools that are commonly available from Park, Wheels, Enduro, etc. These seem nice but they just don’t play well with the 2.0mm flange that is on the T47 bottom brackets. What happens is when torquing with the wrench, it wants to peel off. The vectors are way out of alignment. This makes it a challenge to get enough torque to be done right. The tool manufacturers do sell additional systems to help hold this tool in place, but that seems to be a forced fit rather than the right solution.

For the last decade or so, I’ve been using the PF41 system with thread together cups. This was a pretty nice system. It’s compact, durable spindles, it lasts, it’s really good. The problem was that the industry doesn’t care about that and they’ve moved away from 24mm spindle cranks. It was clear that I’d have to move on to another system. Fighting the industry takes a lot of effort as I know very well. I had lost this round. After some deep thought I decided that the T47 in 85.5 and 89.5 was the way forward for me. The Millennium Falcon was the first of my bikes to use this.

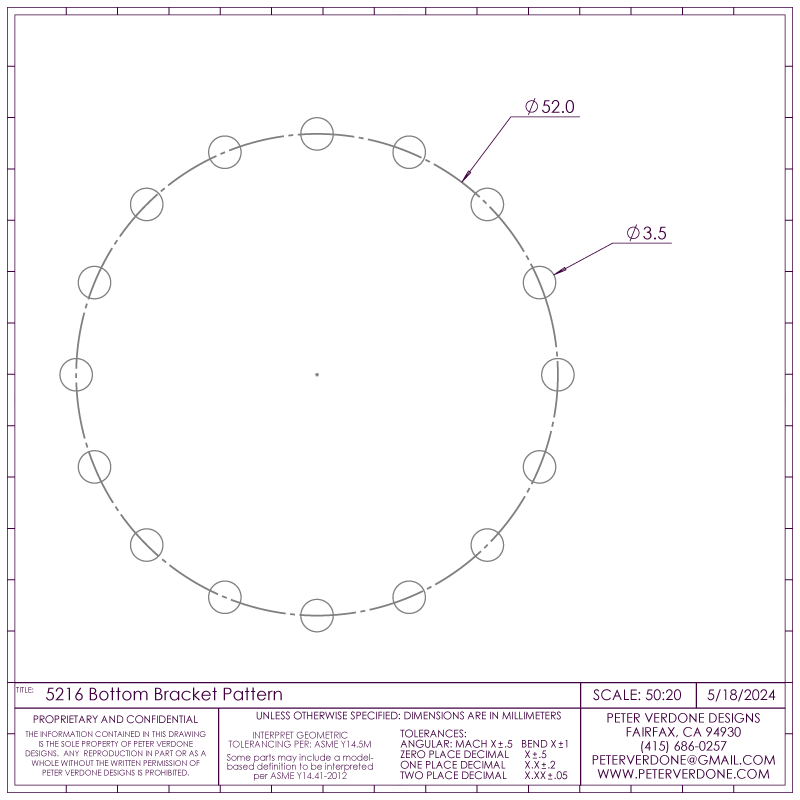

This is the print for the 52/16 pattern. Just so you know. I may have the exact diameter mis-stated so let me know if you are sure.

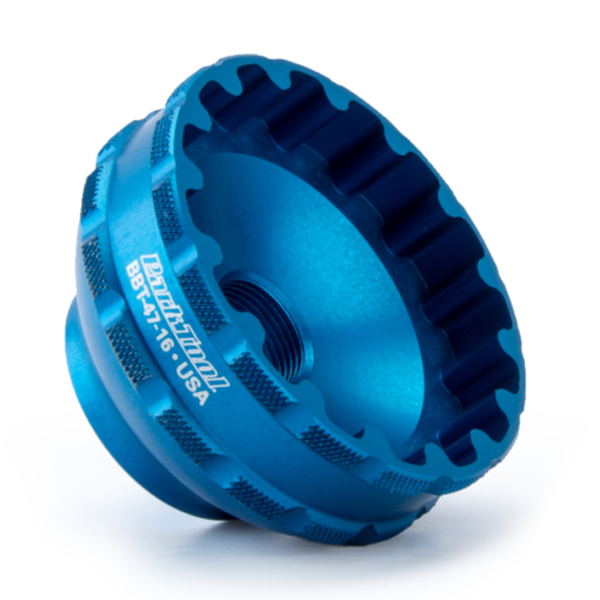

We need a better wrench. What makes this special is that the tool doesn’t cam off the cup flange. The vectors are aligned. A huge amount of torque can go into the system with little effort and without slippage. From what I was able to do with the socket types, this is a significant improvement.

Here’s the right tool to get if you are working with T47. I purchased this tool from Amazon. It cost under $20 and was very precisely cut for fitting the cup. I’d call it a very high quality tool given what it is. Strangely, the only way to get one of this type is through Asian suppliers. The brand name tool companies don’t sell this.

Get one of these. They are cheap. It’s the correct wrench to use for TH47.