The initial prototype of the new skate truck had seen enough riding and evaluation to go to the second round. The trucks were working out pretty well but were still not really where I wanted them to be. I’m looking for a real premium experience with these and the work has to go on until I get there. This is how things like this go. The first prototype may work but has several issues and changes are needed.

Issues with the first round:

- The truck was still far from the weight that it needed to get down to.

- The pivot cup had been designed around a urethane part similar to an Indy/Ace would use. This was instantly overwhelmed causing a course result from the steering input and needed a modification to Delrin.

- The pivot action was far too sloppy as my goal was for the truck to be an analog to a precision truck.

- The new mounting hardware was proving to be a pain when working with varying deck thicknesses and had been tabled for now.

- The baseplates were not optimized for traditional type hardware use.

- I had tried to build in some progressivity into the steering resistance. I had done too much and it needed to be lightened

- The limit screw system worked but needed a complete revision for ease of use without removing the trucks from the board.

- Steering angle needed to be increased for slow speed maneuvering.

- The baseplate at the kingpin needed optimizing.

- The trucks were too low for the given rate of steer and needed to be raised 3mm to get what was needed.

The first issue to address was improve the precision of the truck. Reshaping the pivot and the change to delrin helped considerably. Finding better ways is the trick here as the traditional systems really aren’t that great for precision. The refinement has really added a great feel to the steering as the loading of the system is really good now.

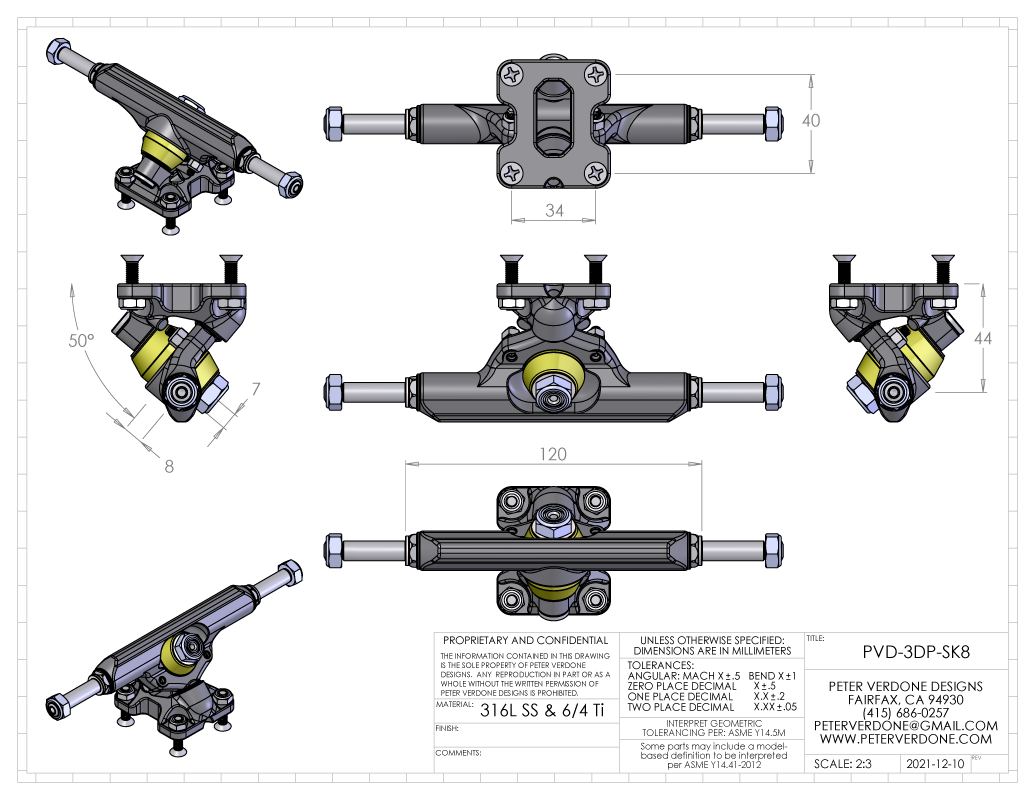

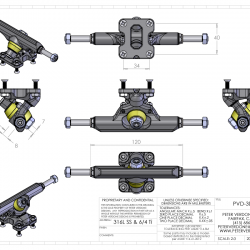

I spent a ton of time reducing the scale of the truck and reducing the weight. 80 grams reduced on the set. 486.7g to 382.7g. This may not seem like much but doing this from a fairly mature model is insane.

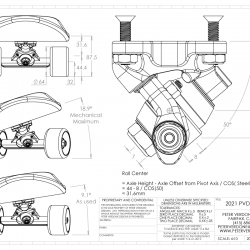

The look of the truck is so miniscule that it’s shocking. From the tiny footprint of the baseplate to the sculpted ‘motobilt’ arms, is just wild.

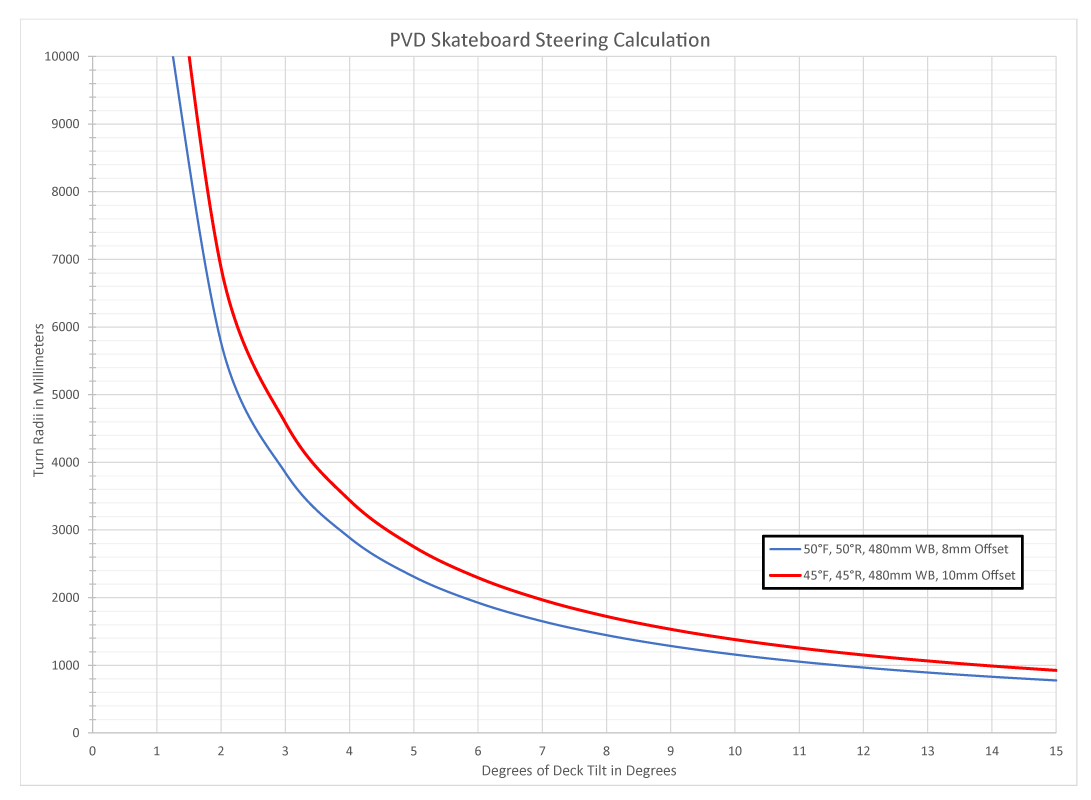

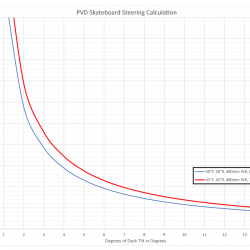

Changing the angle to 50 degrees was a bit of a risk. If I was able to reduce the steering slop and make this change, would it be too much? I think that it is better but may de-tune the rear some in another round. I need more time on the trucks to know.

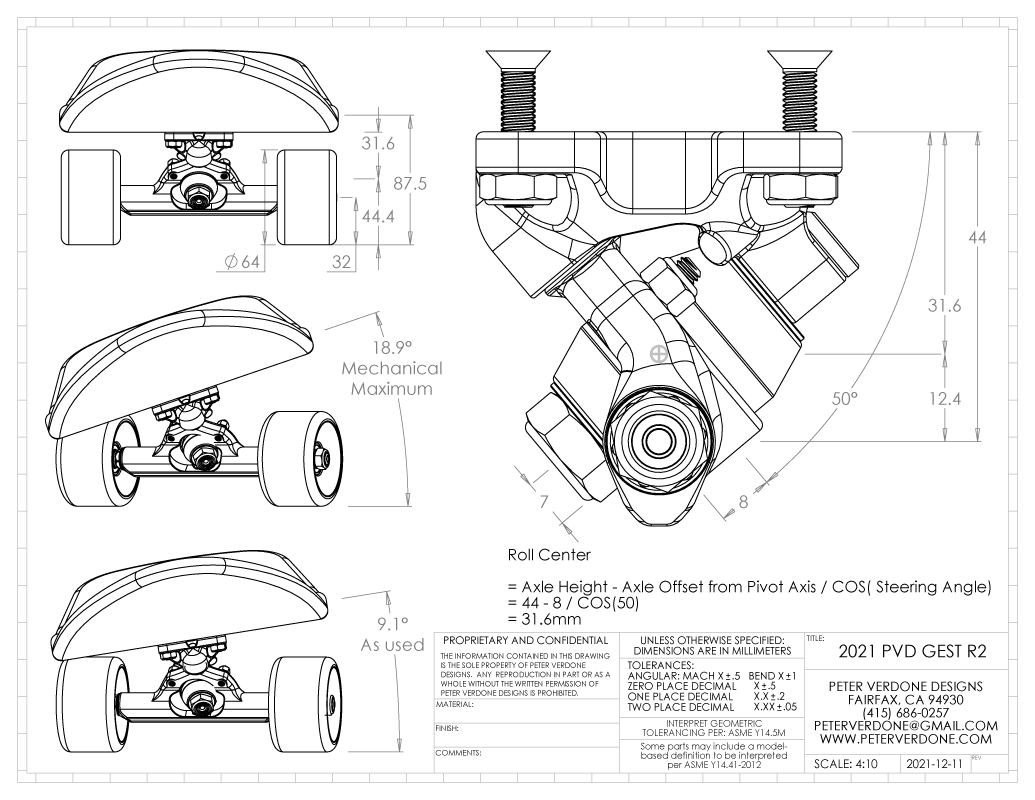

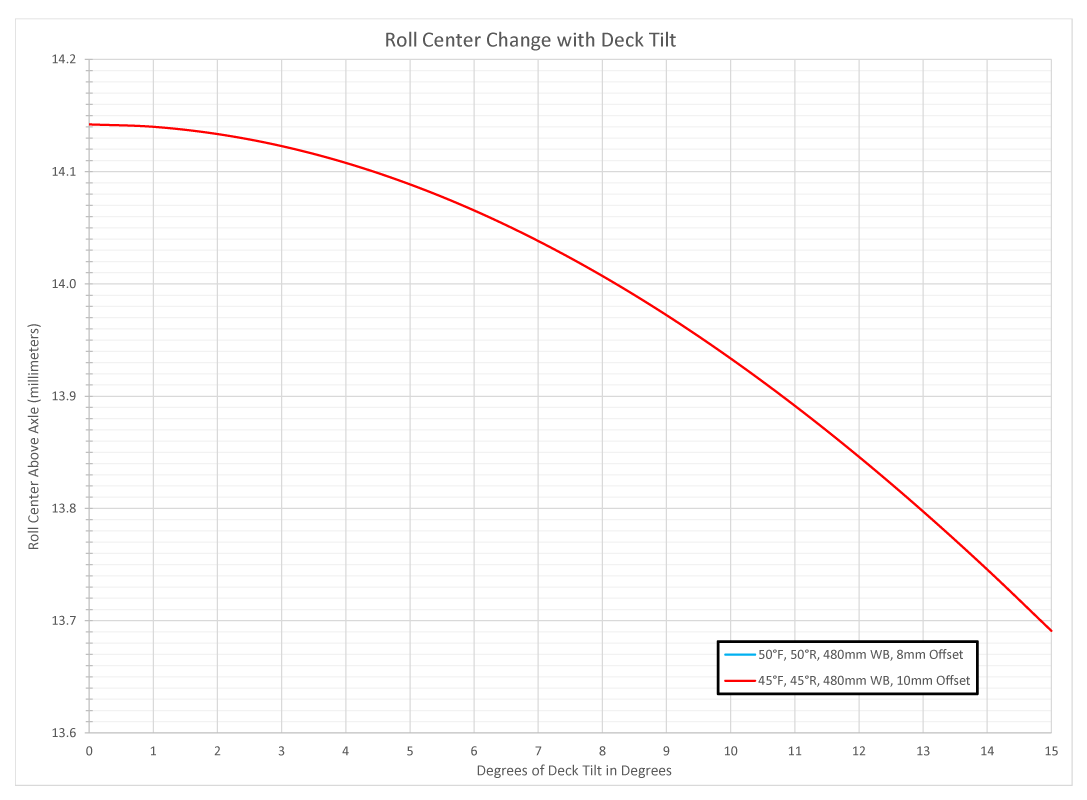

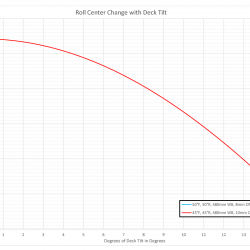

The revised trucks have an internal working angle of plus/minus 28 degrees (18.9 degrees of deck tilt). While this is huge my any measure, in reality the internal angle used ends up being about 14 degrees for a deck tilt of 9.1 degrees. Still, this is theoretical and flex within the system produces significant change from this state. Anyone that has used hard limited skate trucks knows that there is a big difference between what the limit screws are set to and when the board bites the wheels. Everything is flexing so we test the screws into position and this is about where mine ended up set at with this setup.

Given that I increased the steering rate, I only raised the truck height 1mm from the previous version (from 43mm to 44mm) and this seems to have been a good call. The low feel of the deck is superb.

When testing the first prototypes, I felt that the steering was way too progressive. This was causing a lot of confusion when looking for info about what was happening with the limit screw interaction when in full tilt. I moved toward securing some softer bushings from Brad at Riptide. I was on the 90a (yellow) cones. I reduced that progression in these trucks and now the 90a bushings feel just about perfect with a nice easy touchdown to a hard stop at the end.

I changed the orientation of the limit screw locknut at final setup from what it had been in the design. It’s strange how we can’t see some things until we finally can.

Notes for the next revision:

- Optimize limit screw land for expected use rather than max condition

- Re-shape hanger area by limit screw nut to better reflect new orientation

- Reduce limit screw extension

- Source M4x18 stainless flat set screws

- Hex socket on inside of axle on hanger side

- Increase stiffness of hanger toward axle end

- Add chamfer to baseplate cutout similar to R1.

- Figure out a more captive system for top and bottom of bushing stack.

- Riptide ‘hard-cores’?

- Clean up pivot cup push hole chamfer in baseplate

- Reshape pivot pin, cup, and socket to reflect new shape method.

- Invert kingpin

- Add range of lower bushing options to allow barrel shapes in addition to cone

- Improve axle thread interface at hanger

- Increase filleting that may contact bushing (near limit screw)

- Improve tooling for post processing pivot cup bore

Casual initial testing is going well. The trucks are functioning at a very high level. The issue that I’m having is pushing the board hard at the limit of the turn. Unlike commodity trucks that fold over and bite at the limits, these don’t. The truck turns predictably and solidly up to and against the stops. That is where my issue comes in as I keep falling off the board on the low side. There is a way to do this, hitting the limit and really loading the energy into the deck, but I’m not there yet. Then the issue of traction. Pushing that hard at the bottom of the turn is problematic with harder (64mm, 82a) wheels.

I’ve got a challenging modification to do to the pivot cup area that should help me tighten up the precision. I’ve been revising this area over the last month or two and it keeps getting better, but slowly. I think I have it figured out and have just enough metal that I can remove to make it possible to make the most of this iteration. The cutting tool has been ordered but is a week out so I won’t know for a bit where this goes.

Regardless of this, the feel of the system is pretty amazing. The load bearing of the truck makes input so crisp. The (theoretical) deck height of 87.5mm means that kicking is so relaxed and easy. This really is a winner for commuting skating.