On Wednesday (06/19), I was doing a ride around the Tamarancho loop. Simple stuff for an end of the day ride. I was a bit frantic, though, as I was working hard trying to keep ahead of a group that I had passed earlier.

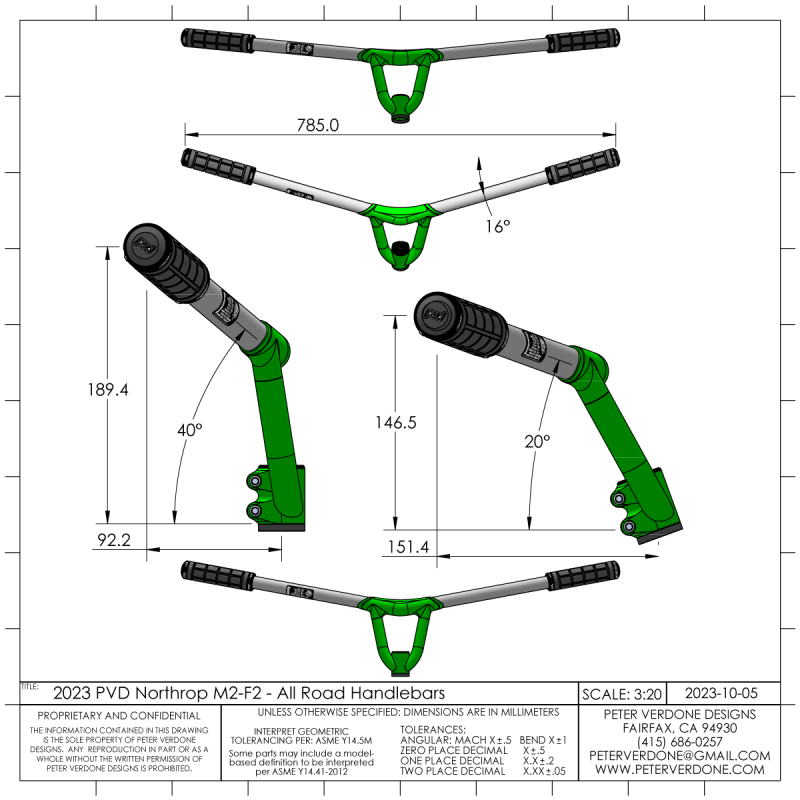

I was on my 2023 M2-F2. I love this bike. It’s ugly as hell but works incredibly well. It rolls so well. The feel is crisp. I’m sure that I do over half of my rides on it.

Clockwise, and working my way down Wagonwheel, I had just gotten up the little ass kicker and was bridging to the start of the big rock garden when my left handlebar end snapped. Quick and clean. I hit the dirt hard. My right side took the hit. Flesh torn. It ground my knee up good. My elbow and back got it good too. It was rough.

Once again, I was on a long walk back home from the depths of the trail. I was in good spirits though. Engineering a fix for a failure while still in the moment on the trail is a fascinating experience. It takes a bit of time to walk your shame to the road. Plenty of time to go down a few rabbit holes.

I feel terrible about what happened in a few ways. Obviously, it sucks to have another failure. Yes god, I suck. Worse, I had felt something in the bar earlier. I’ve learned to recognize the start of a bar failure but I was so busy trying to outrun the other group that I didn’t stop to check it out. I paid dearly. Lesson learned about working with prototypes: protocol first, everything else second.

This is a new type of failure in my handlebar development. The titanium tube failed. I discuss this at length in the accompanying video.

We have a combined set of conditions that produced this. Just one on it’s own may not have done it but the mix ensured it.

- The internal support was short and didn’t support the correct location in the design

- Without support, the stress riser in the lug scallop had magnified effect

- The tube is very thin, leaving very little safety factor

- All bar flex is being done at the transition to the titanium tube (unlike the mtb bars)

- The quality of the titanium is expected to be low.

I should be able to keep this assembly functioning with just removal and modification of the titanium strut.

- Proper length and placement of the internal support.

- Reshape the lug to minimize the stress riser in the scallop.

- Increase the tube wall thickness.

In new versions of the all-road/klunker bar design, I will:

4. Improve the lug profile to increase the flex that can happen in the main structure so that the duties are shared like on the mtb bars.

I’m working on finding a source for better tube material:

5. Source high quality material

This sucks…but lessons have been learned. This is development. Love the game.

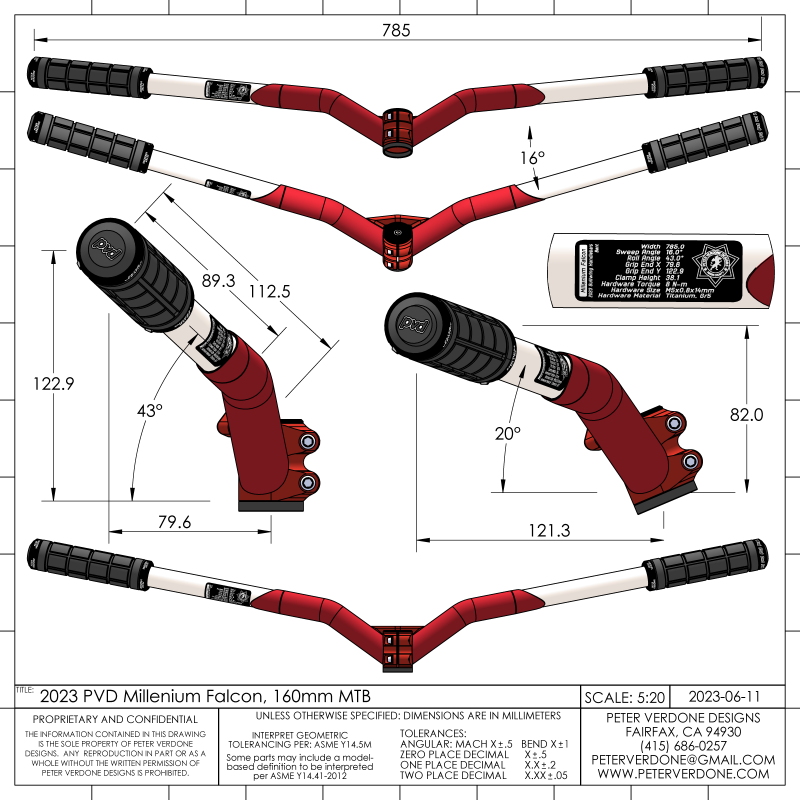

The design of the bar lug for the M2-F2 differs from the mountain bikes as seen on the Vega and Millennium Falcon. Since there isn’t as much vertical translation done in the bar so there needn’t be the upright struts that contact at the end of the lug. There’s just more opportunity for the lug to flex before transitioning to the bar end on the mtb bars.