Not really, just some fine tuning.

This is my first real “cuttin’ metal” modification to my AR-15 platform. I’m playing with the stock trigger mechanism trying to make it work well. Similar to my work with motorcycles, I’m trying to focus on modifications and cash outlays that actually make a difference and return on the investment rather than make me feel like I spent a bunch of money and don’t know why.

The trigger had been lightened up a little already from 6.5 to 5.5 lbs by using a cheap Wolff ‘upgrade’ spring. Simple enough. $5.99 spent.

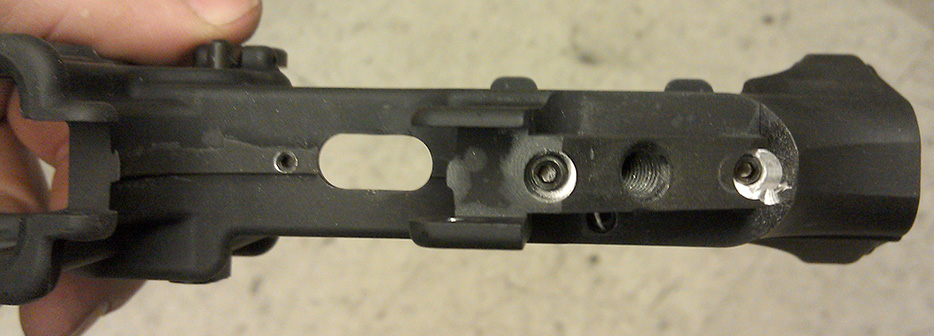

The modification that I’m doing here essentially adds limit screws to the trigger. The front screw controls the over travel of the trigger when it is pulled. The rear screw controls the initial position of the trigger and therefore the amount of pull prior to release. Only the small front screw is visible when the gun is assembled.

Another set screw was added farther to the rear of the rifle to act as an adjustment to reduce play in the take-down pin area. Rattling receivers is a pesky issue with cheap mis-matched upper and lowers.

After fitting everything together I can make this assessment:

* The screw for the take-down play is challenging to get fine tuned and gets mixed results. I’m going to try a nylon tipped set screw to see if I can get better results. I’m waiting for that in next weeks mail.

* The front (6/32) limit screw isn’t super important but it’s nice. That screw would handle over travel of the trigger. Over travel on the AR15 is minimal but it does exist. This screw gets rid of the majority of that travel and produces a nice feel at the seer break.

* The money shot here is the rear trigger limit screw. Wow! What a difference. The trigger feels amazing now. This screw controls the beginning position of the trigger. I haven’t shot it yet so there could be some issue but it’s just dramatically improved. It takes just the right amount of movement and effort to release the hammer now. Just a short stroke and very controlled. Combined with the over travel screw, this is a beautiful modification.

When doing this again, I will probably change the rear trigger adjustment screw to be an #8-32 screw. The #10-32 is a bit larger than need be and the smaller #8 could provide better positioning.

This is a must do modification to AR-15’s using stock triggers. I did have to trim about 5/16″ from the pistol grip screw for clearance due to the crossing paths of the threads but this is not a concern unless swapping grips and hardware.

Holding the receiver in the mill vise is tricky. It’s a flimsy part and has an odd shape. At one point milling the counter bores the part slipped. If I do more of these operations in the future, I’ll make a special ‘take up’ tool to give the part some girth and allow me to clamp it well.

Screws: 1x 6-32×1/4″, 1x 10-32×1″, 1x 10-32×3/4″