Last week, I had a tool fail in the shop. A shaft. A flexy one. A moment of carelessness combined with over a decade of use snapped the end of the shaft where it connects to the motor of my Foredom SR flexible shaft tool. This can happen as it is the consumable part of the system…other than brushes and burrs.

The replacement part is a little tricky go get as I have the 66″ shaft option on my unit. So it’s not widely available. The replacement part is the S-93-99 inner shaft. So I had to order it factory direct at $19.22 + shipping. Not bad considering how important this tool is in my shop.

I was sharing photos of the broken parts on Instagram and some folks sent me questions about it all. So, I’m making this post about this crucial yet little discussed corner of the shop. The shaft area.

I call this my “six axis machining center” as it can be used in all sorts of complex situations to cut material from a part. I can work as a jeweler or sculptor in the machine shop, removing the smallest amount of material from a very specific location. That is, provided that I have a the right burr on hand and can see what I’m doing. I have other spinning shafts around the shop from die grinders to angle grinders that get used in this way as well. These tools are important.

Because on the Foredom I’m controlling the speed of the burr with my foot, both of my hands can be used to hold the cutter and the workpiece. Also, since the motor is well away from the work area, my tool is light and easy to control even as some serious torque can go through the system.

This is why you don’t see a Dremel tool in my shop. Those are toys and have little value in my world. They have little range of shaft diameters (1/8″ max) and generally are bulky and heavy in the hand. I really hate when I’m forced to use one of those things. The worse part is, if you get rough, the burr snaps.

I have six handpieces for my flexible shaft tool along with a 9″ extension for 1/4″ burrs. The burrs come in a variety of profiles, diameters, cut lengths, and overall lengths. Most often, the burr is solid carbide or has a carbide cutting end. These things eat steel for breakfast. McMaster or Amazon have a huge selection that have affordable prices.

For remote work when I need a high power tool, I keep a Makita GD0800C 1/4″ SJ Die Grinder at home. Yes, this is a big heavy electric die grinder but when you need to send splinters flying, this is the tool for the job. It was an emergency purchase years ago. It got me out of jail, figuratively speaking. Now, it is my ace in the hole.

I have a collection of standard to small pneumatic die grinders and cutoff wheels. The cool ones are the MAC AG14 and AG14AH. These are such tiny little things that fit easily into a tool box and in the hand. They are for tight quarters work. Pneumatics are very inexpensive and if you do have access to air, there’s no excuse for not having them.

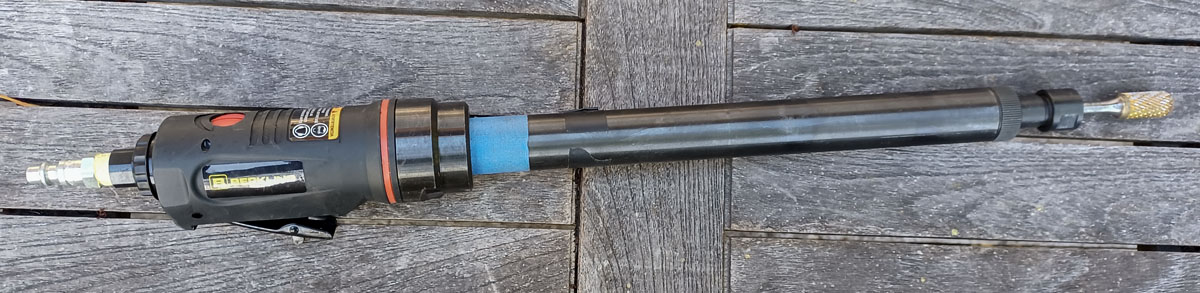

A very cool tool purchased from Amazon is the Berkling Tools BT 6321-12, 12″ Extra Long Extension 1/4“, Straight, Air Die Grinder. This solves an amazing problem cheaply. You can reach deep into a tube to do work. Get one!

The wrenches that are typically supplied with these tools leave a lot to be desired. They are most often cheap stamped steel that open up as they get used. I got some thin Facom Midget double open-end wrenches to keep in my stash to help prevent a future problem. Decent cheap thin wrench sets can be found most places.

So there it is. My collection of surgical tools that I use when making bike frames and other things.