I’m a very lazy mechanic. I don’t want to do any more work or pay any more attention than I need to when I’m repairing something or tuning a system. Because of that, like most mechanics, rather than use a torque wrench on every bolt I turn I’ve learned a feel for the metal, parts, and tools that allow me to do good work. Sometimes, we really do need to use a torque wrench. Engine work, some specific bolts, and when the customer is watching over your shoulders.

The bicycle is one of the easiest systems for someone to work with. Nothing on a bicycle needs to be tightened with a torque wrench. Good hands and wise eyes will get the job done well every time. Still, recent product developments have produced tools that might allow me to work quicker and taking less care to get just the right torque. Specifically, cheap low end preset torque drivers. I bought a few to see if I could form a habit around them.

Park Preset Torque Drivers, PTD-4, PTD-5, and PTD-6.

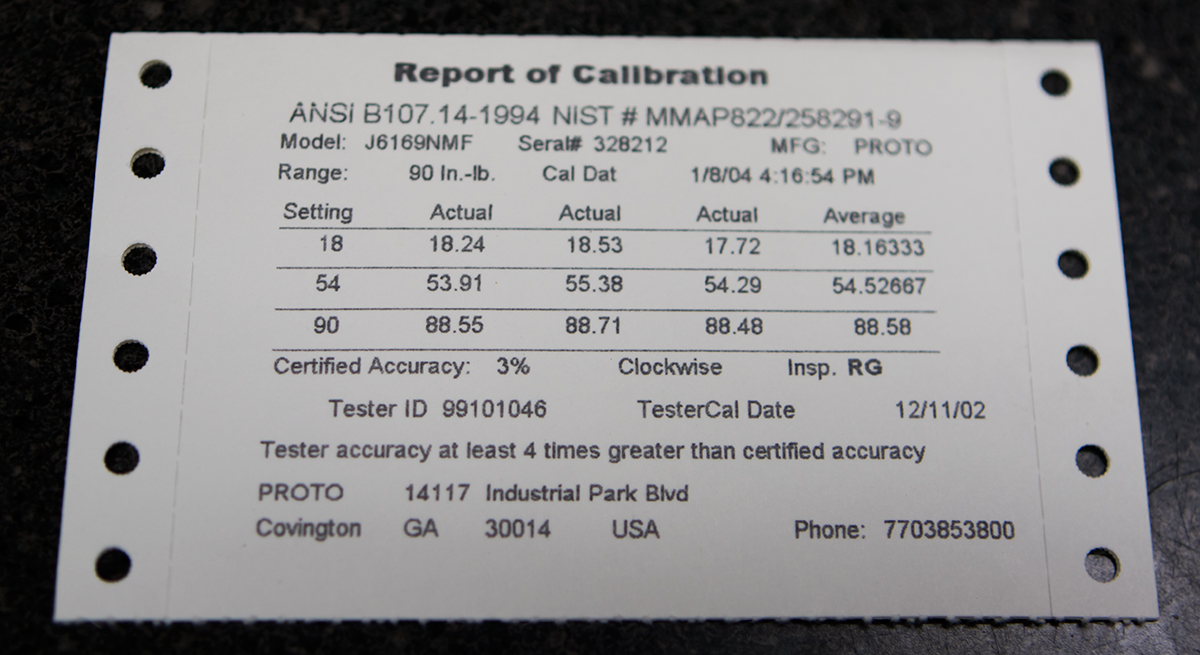

Of course. I don’t use any measurement tool without comparing to a standard. For this grade of tool, comparing against a high quality torque wrench would be fine to validate the tools. I used my Proto J619NMF (Proto catalog p. 542). It’s a very nice fine indicating wrench from an awesome company. It’s supplied with a calibration card as well. That’s pretty good for basement work, eh.

The results were very good. I was surprised. I expected far worse.

My measures: (note that in photos, true measure is one click below what shows)

PTD-4 : 4.0 N-m

PTD-5 : 4.6 N-m

PTD-6 : 6.0 N-m

Since the PTD-5 was torquing low, I pulled it apart and adjusted it to turn 5.0 N-m. It’s an easy process. Simply move a set screw in and out. I’ve got another one of these on order for a total of 4 wrenches. I’m going to reconfigure them to my own torques for fasters I typically work with. Some will be up to 8 or 10 N-m another down to 2 N-m.

I’ll be checking these numbers again in a few months of use to see if and by how much they change. Fingers crossed for good cheap torque tools.

TORQUE:

We can’t discuss these tools without discussing torque on some level. I’ll skip the academic explanations as you can find all that on Wikipedia. What I will provide are torque conversions and recommended torques for various screws.

A motorcycle mechanic needs at least 2 high quality torque wrenches.

- 50-250 in.lb. (.5ft/lb) 1/4 or 3/8 Drive, Dial Type

- 10-100 ft.lb (1 ft.lb.) 3/8 Drive, Micrometer “Clicker” Type

High quality torque wrenches are available from many companies. I tend to recomend SK/FACOM or Stanley/PROTO torque wrenches, although many other brands are just as good. They are very rugged and finely made. They come with calibration cards and have a vast support and dealer network. You should expect to pay between $150 and $200 for a good wrench. Many online dealers sell these wrenches for far less than MSRP. I tend to shop for torque wrenches at ToolSource. They have one of the best selections and decent pricing on over two hundred different wrenches.

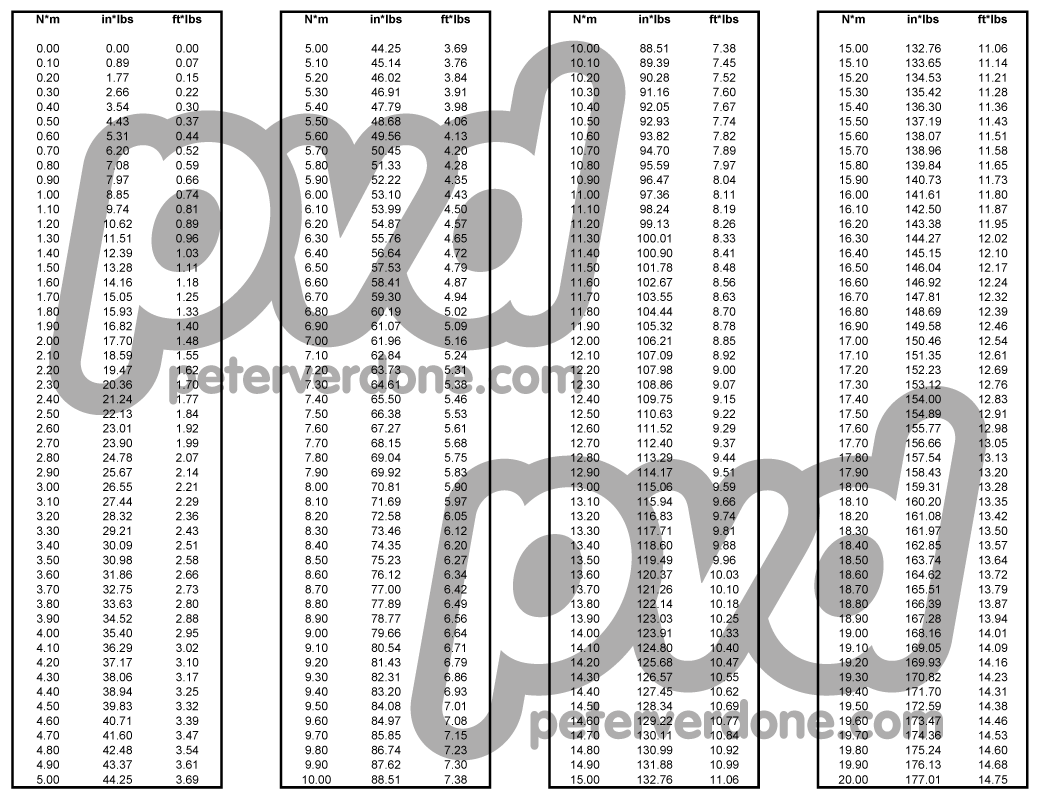

I have made three handy torque conversion charts that I keep with each of my wrenches. They convert between the three mainly used torque scales, in*lb, ft*lb, N*m. CHART 1, CHART 2, CHART 3.

Here is the chart most handy for the bicycle mechanic:

For fastener torque recommendations, Holo-Krome has a handy chart here.

Maryland Metrics has another very good chart here.

For bicycle specific torque recommendations, three sources are very good: Park Tool and BicyleTutor.

Projects:

Back in 2007, I made a cool tool for adjusting Shimano SPD pedal release torque. It was nice and comes in very handy when setting up race bikes.

I made an improved version of this in 2018.

I DO NOT recommend Snap-On torque wrenches for the casual or semi-professional mechanic. If you do not handle a tool several times a day, then you are wasting lots of money paying for Snap-on tools. Snap-on makes very high quality tools and special tools for automotive and industrial applications. They give very good direct support for their product, but they are priced at an absolute premium for the support they give. Often, a tool identical to a Snap-On tool can be found from another supplier for about half the price. The same things can be said about MAC or Matco tools, but Snap-on tends to ride at the top of the list.

At the opposite end of the spectrum, I do not recommend Craftsman torque wrenches. While the are widely available at any Sears or Orchard Supply Hardware store and are inexpensive compared to most torque wrenches, but they should not be purchased. They are poorly manufactured and designed. The plastic parts tend to break and the tool becomes useless. They are also not available in specific ranges that are truly useful. These are really a waste of money on every level for the motorcyclist.

Here’s a really nice tool. The Proto 6106 Torque Screwdriver. The range is 2-36 in-lbs (0.25-4 N-m). It’s for very very fancy work.